i want calculations for w x h x d ( 80 x 10 x 1.5 ) mm thick copper bus bar. Hi, pls post the busbar sizing calculation, Thayathidavan Gopalan Bsc Engg (Hons),MBA,FIE ,C Engg.

I want to learn how current capacity is decide based on cross section or dimensions or vise versa. thanking of you. thanks.

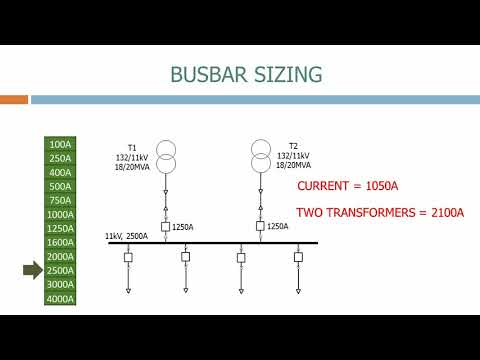

Limited Time Offer (expires soon): Save 15% on Pro Plan with code: NTX78. Consultant Recommended Busbar Size based on the 'THUMB Rule' We noticed, Busbar Size is Low to Carry 6300A.

Hi, can you help me regarding how 1547A value came ? Please, how do i select the correct size of a bursar for my feeder panel. I'm running 8x230 cells in series, max continuous is .5 capacity, so 115A continuous if the battery is full capacity. Is it possible that it is for AC? and pls share the formula.

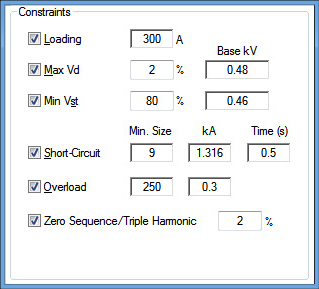

Dear Sir - Can you provide me Temperature rise calculation (inside Enclosure) for considering 35deg rise above 50deg ambient temperature. While Practicing 'THUMB' Rule people should aware the Quality Standards of Aluminium & Copper Bar. Any suggestions or thoughts on how to improve The Book Of Engineering would be much appreciated. [Either ACB or MCCB].

Thanks I would use existing bars and have a second battery in parallel. Comparing 'THREE', the most dangerous one is 'ACCIDENTAL'. Calculation as a whole is not having any clarity. Here it is not the case for the carrying Short Circuit Current. Consultant Challenged Contractor that, His recommended Size of Busbar will carry full load Current, then Contractor approached 'CPRI Testing for their internal verification.

Here Electricity plays major role for the Fire Accident most of the Times. [Ex. Thanks for dropping by! I want to learn how current capacity is decide based on cross section or dimensions or vise versa. Generally there are 'THREE' Factors are involved for the Fire Causes.

K3 is a Function of the Mounting Arrangement.

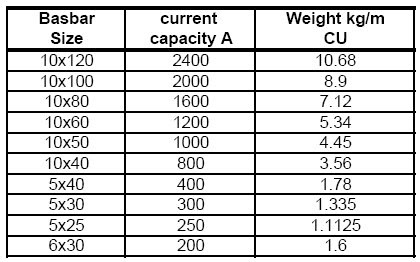

Panel Fabricators should not take responsible in case Panel gets fire due to the Busbar Under Sized. The Design Engineer should consider the following points while doing 'BUSBAR SIZING CALCULATION': Maximum Permissible Temperature Rise for bolt - connected devices, including busbars. This is anecdotal, so take it for what it's worth You must log in or register to reply here. Sol Ark: Ultimate Code Compliant Inverter, Grid Tie Solar Advisor (If you do not want to DIY your system, use this tool), Electrical: Busbar - DC Copper Busbar Ampacities, Busbar Current Calculator Online | Electrical4u, https://www.westmarine.com/WestAdvisor/Marine-Wire-Size-And-Ampacity, What Busbar size for 600A in 3P4S 816AH 12V, different sources different sizes and different ratings, 32x EVE LF280K pack configuration - need second/third opinion. That Source should be Top in the above list. Under Sized Cables]. To Carry the Current of 1067 A, One Run of 80 x 10 mm of Copper Bar is enough. e) POOR QUALITY IN DESIGNING.

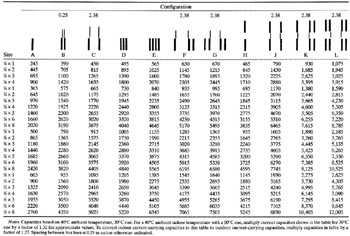

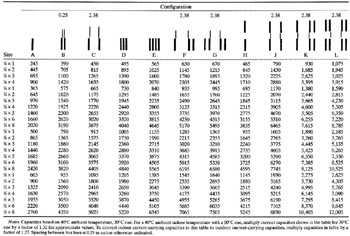

When are you visiting our place next? I'm noticing conflicting calculators (top 2 google results) and wondering if anyone can help explain the differences: The following tables have been provided by the Alliance for Telecommunications Industry Solutions (ATIS), T1 Committee, and represent ampacities for busbar sizes and arrangements typically found in the telecommunications industry. The Book Of Engineering material is copyrighted, however it is provided with NO WARRANTY or LIABILITY. People not have that much Patience for the Practicing Calculation. There are 'THREE' Elements must be present, for a 'FIRE' to initiate.

The content is copyrighted to EEP and may not be reproduced on other websites. Tell us what you're thinking. I want to connect the low voltage side of the transformer to a feeder panel with three busbars for the three phases and one bursbar for the Neutral that feeds risers. These are Oxygen, Fuel and Heat. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Sorry, preview is currently unavailable. The copper.com page specifically says it is for DC bus bars.

please explain in detail.

Thanks, this clears things up a bit. Avoidance of mechanical resonance under normal operating and Fault Conditions.

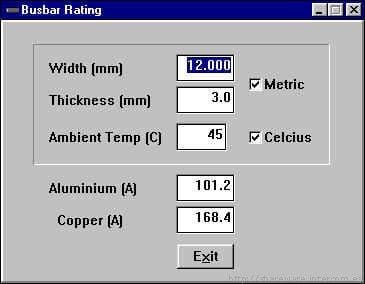

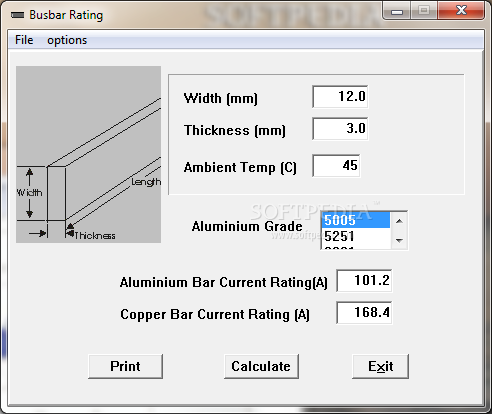

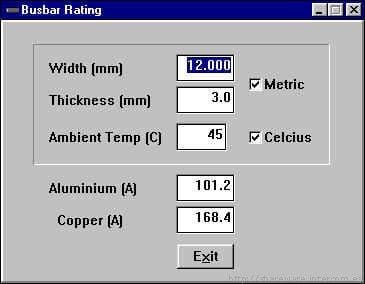

Bolting Arrangements for Continuous Busbar Connections. Then press the calculate button, you get the aluminium or copper busbar. 16S bank layout and bus bar sizing questions. +966-538436912. So, the bus bar 100x25x1.5 is suitable for =(100*25*1.5*0.8)=3000A incomer current. To view or add a comment, sign in

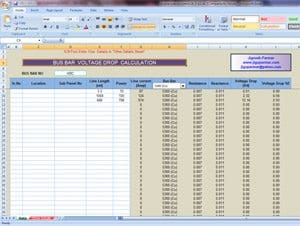

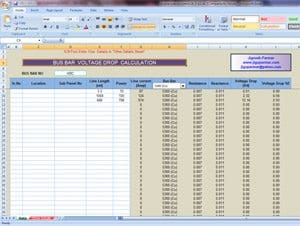

Can you please send to me the calculation of bus bar riser voltage drop. Thank you, je narrive pas tlcharger les fichiers excel.

If we consider 80 x 10 mm of Copper Bar, How many bars required to carry full load current of Transformer Secondary End ?

Selection of Adequate Busbar Insulator Standoffs. Correct if I am wrong. Study specialized LV/MV/HV technical articles and guides. Final calculation of current 1547 is confusing. Because some case people will add Tolerance in the Positive End.

You can then calculate bus bar rating based on the total connected load supplied by the bus bar and rate you bus bar based on percentages of full load current of connected load. Enter the breadth and thickness of the busbar; do not enter the length of the busbar. You have 2500A, 2000A, 800A, 1500A, 600A, 250A, you size bus bar rating based on the three parameters total connected load of the system, fault level of the system, Do I have to subscribe to every download or technical article I need? What is the recommendable size of Copper Busbar in the LT Panel ?? A) copper.org uses Table 5 from ATIS Standard T1.311 and assumes a given temperature rise over ambient. Can u pl explain hot to calculate current rating of bus bar. we need excel sheet to calculate voltage drop in bus bar , kindly send me without protection.

According to the Main Formula, Derived Value will be = 1547A???? Let's have a professional and meaningful conversation instead. Adaptive Relay Scheme with Dual Protection Techniques Based On Differential and Alienation Principles, Medium Voltage technical guide Technical collection Basics for MV cubicle design, Medium Voltage technical guide Basics for MV cubicle design, Power Systems Modelling and Fault Analysis..Theory and Practice-Nasser Tleis, Power Systems Modelling and Fault Analysis, Electrical network protection User's manual 06/2008 Sepam series 40, UNIT -II RECTIFIERS, FILTERS AND REGULATORS Introduction, Copper for Busbars Guidance for Design and Installation, TRANSMISSION & DISTRIBUTION OF ELECTRICAL POWER, DCS800 Hardware Manual DCS800 Drives (20 to 5200 A, TECHNICAL PERFORMANCE AND STABILITY ANALYSIS OF ESKOM POWER NETWORK USING 600KV, 800KV, AND 1000KV HVDC, Catalog HA 40 2 Switchgear Type 8DJH for Secondary Distribution Systems, KAUST Hotel VOLUME 3A (6 OF 6) ELECTRICAL SPECIFICATIONS SEPTEMBER 2017 CLIENT OPERATOR LEAD CONSULTANT INTERIOR CONSULTANT COST CONSULTANT, Shipboard Propulsion, Power Electronics, and Ocean Energy, introduction-to-instrumentation-and-measurements-2-edition-by-robert-b-northrop.pdf, Preface Introduction Quick Current Transformer, Short-Circuit Method IEC 61363 Technical Reference, Electrical installation guide 2009 According to IEC international standards Technical collection, Electrical installation guide According to IEC international standards Electrical installation guide, Catalog 2014 Electronic Products and Relays, Electrical installation guide 2013 According to IEC international standards, Instrumentation for Automation and Process Control for Engineers and Technicians, Electrical installation guide Schneider Electric Industries SAS Technical collection, Aircraft Electrical&Electronic Systems[Tooley], A compact frequency-domain photon migration system for integration into commercial hybrid small animal imaging scanners for fluorescence tomography, Influence of dc Component during Inadvertent Operation of the High Voltage Generator Circuit Breaker during Mis-Synchronization, Deflections of Reinforced Concrete Beams and Columns. According to the Formula as per IEC 62271 - I, According to the Main Formula, Derived Value will be = 1547A. Anything else apart from the Above,.Yes. for the Area 800 Sq.mm [80 x 10 mm], Current Carrying Capacity will be 960A.., Then additional one Run of Busbar needed to carry the Current of 1067A. in case of copper bus bar the current carrying capacity is 1.2(max). For a better experience, please enable JavaScript in your browser before proceeding. Copper.org's table is 30C over 40C ambient that's pretty darn hot! Hi. i.e They used 0.75 Amps / 1 Sq.mm of Bar & 1.4 Amps / 1 Sq.mm for Aluminium & Copper Respectively. aluminium bus bar current carrying capacity, aluminium busbar current rating calculation, busbar current carrying capacity calculator, copper busbar current carrying capacity calculator.

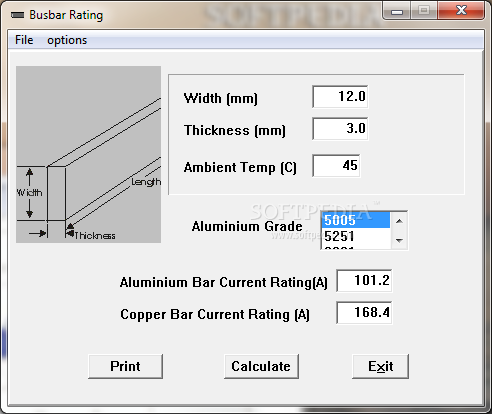

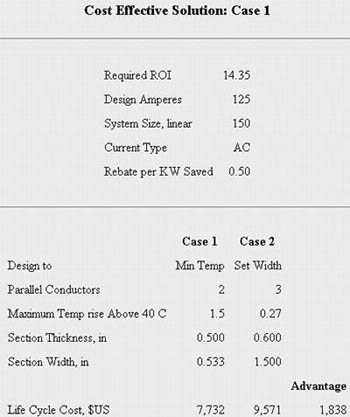

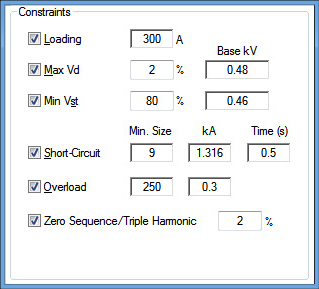

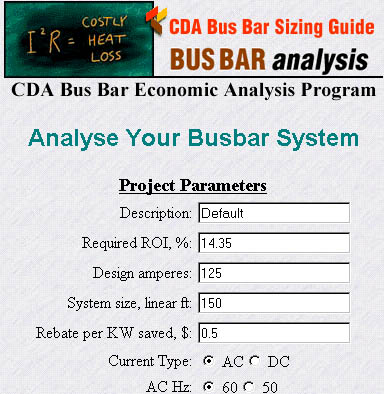

Now Software available to determine Proper Size of Busbar for the panels.

how you gets this value totally confusing, Hi All, 960A X 1.6 = 1536A for 2 Parallel Run. Good morning sir. Here I will like to describe Busbar Sizing of LT & HT Panel System. It seems authour not studied the related formula correctly. I guess it really comes down to heat and voltage loss then. Sometimes we didn't aware the bar Quality which is used by the fabricator in the Panel. So, please do not use a spammy keyword or a domain as your name, or it will be deleted. i want to determine the size of busbar i can use in the panel.

They are". For Copper:1.2 Amps / 1 Sq.mm of Copper. K4 is a Function of the Installed Location. Enter the email address you signed up with and we'll email you a reset link. [That Panel should cater 10 MW of Power of the IT Building, Panel gets power from 3 Transformers & 6 Generators]. SOURCES for the 'HEAT' in the 'ELECTRICAL SYSTEMS' : Most of the Time, Fire happens in the Electrical Panels, Which we observed from the Existing Cases. To view or add a comment, sign in. Adequate minimum required clearance between Phases and Phase to Earth. Normal loads will be more in the 70-90 range, but since I'm running a 3000W inverter I want to make sure my wiring is capable of at least 125A (24v) with some room for surge or accidental high loads. For Aluminium:0.7 Amps / 1 Sq.mm ofBar. hope everything is OK. It may not display this or other websites correctly. Thermal Effects on Busbar and Insulator Standoffs under normal and Fault conditions. So it is better to mention that, Sources for the 'HEAT' in the Electrical Panels.

A 3000 watt inverter can draw up to ~150 service amps at 24 volts. The bus bar 100mm x25mm x1.5mm is suitable for incomer current =(100*25*1.5*1.2)=4500A. Ajay What is the parallel grouping factor for "N" no.of bus bars. You can download the paper by clicking the button above.

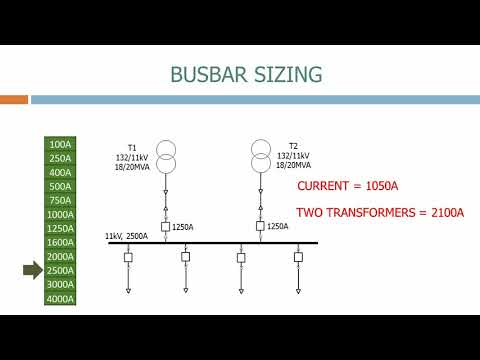

Panel should capable to Carry 6300A. please explain in detail. He should have to answer Client, Electrical Inspectorate & Consultant.

After that we will fabricate the Panel with Proper Sizing of busbar which we derived from the Proper Calculation. While This Methodology doesn't haveany relation with 'CALCULATION OF CONDUCTOR BUS SIZING [ACSR]' for the Switch yard Projects. Consultant given Busbar Size for the Main MV Panel. There is formula exist apart from the 'K' Factors. If Busbar doesn't able to carry the Full Load Current, then how it will carry Short Circuit Current for the Second.??? Pl share the main formula. In doing so, I decided to ditch the 2/0 cable where I could and use 150 amps out of 230 cells seems like a lot. K5 is a Function of any Artificial Ventilation.

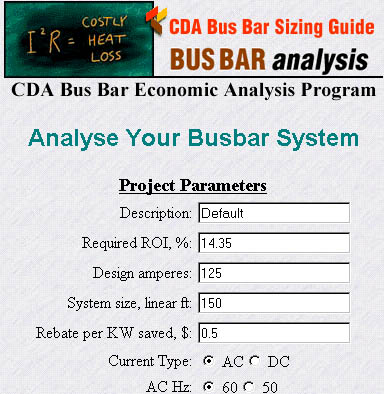

The Cost of the Aluminium bar in the Market based on the Quality. Solve some math:eighteen=nine. Ie. pouvez vous maider? Electricity Plays major role to provide 'HEAT' most of the Times. I'm trying to decide if I should build my own busbars (for higher ampacity) or if the bars that came with my 230AH cells are worth using. I have a transformer rated 500KVA 11kv/0.45kv. Can u pl explain to calculate current rating of bus bar. Prove that you are not R2-D2. Finally Busbar gets melted when it carried full load Current [6300A] for the interval 1 Minute. For 1067 A nominal current, we need 2 Parallel Bus Bars to be used. For Copper : 1.2 Amps / 1 Sq.mm of Copper. Does this 3000w 12v configuration work; and how should this kind of system be grounded? Calculate Bus Bar Size and Voltage Drop (Spreadsheet), Select Size of Bus Bar for particular Load, Enter Your Sub Panel Details like Load,Line Length.

For Aluminium : 0.7 Amps / 1 Sq.mm of Bar. K2 is Corresponds to the Surface Finish of the Busbars. In some cases people only practicing Calculation with only consider the 'K' Factors. Transformer Rating : 11 / 0.433 kv, 800 kVA Transformer. Normally K factor together will come to .66 .. Please provide an example unable to understand that how to use..?? I would like to share one of the Example I experienced in my past. For the exact results please refer to your busbar providers data. We care about your opinion!

All applicable national and local legislation, standards and practices must be strictly followed and adhered to in this regard. Busbar Clearances as per IS : 4237 - 1967. Electrodynamic Forces applied to Busbars and Insulator Standoffs under Fault Conditions. Hi. This is a Parallel grouping factor . I hope the calculation result declared wrong.

This Article Gives Clear Picture of 'BUSBAR SIZING CALCULATION' and What Care We should have to take 'Sizing of Busbar'. Hi Ajay, how things are moving there? Academia.edu no longer supports Internet Explorer. svp.

i want calculations for w x h x d ( 100 x 25 x 1.5 ) mm thick copper busbar. I would like to add more inputs in this article, which I had experienced in my past years. Please don't hesitate to send us an email or use our feedback form. You need to determine the faul level of the systems and full load current from the customer to determine the CB rating. It's highly advisable to double-check important information with other sources. Bus Bar rating are standard sizes based in iEC and IEEE. and pls share the formula. The 'Electrical Design Engineer' Should have in-depth knowledge of 'Sizing of BUSBAR for the Electrical Panels [Both HT & LT]. in case of aluminium bus bar the current carrying capacity is 0.8(max). This is an estimator for busbar current carrying capacity. thanking of you.

Both Calculations having different Steps & Procedure to find Final Results. Transformer Secondary Full load Current = 1066.72A, Breaker Size Needed = 1250A. Make it a point to visit Mysore and meet us. Here the above mentioned rules are not standard. Also 1547A figure to be replaced by 1536A. It will help you. I'm in the process of rearranging my system to make way for an inverter/charger upgrade. Please keep in mind that comments are moderated and rel="nofollow" is in use. Thanks for your quick response. The other site makes no mention of AC or DC. So People should take More Care for Busbar Sizing for both LT & HT Panels. where is from these informations? The Total 'K' Factor derived from Six 'K' factors, which is listed below : K1 is a Function of the Number of Bars per Phase and their space. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Get access to premium HV/MV/LV technical articles, advanced electrical engineering guides, papers, and much more! It will directly hit EPC Contractor Market Value in the Industry.Also it leads to Black Mark in their Industry. I have seen many times in my past experience, Most of the Engineers doing Busbar Sizing Calculation by 'Thumb Rule' Method, Even though Some of the Senior Engineers in the Consultant offices & Leading Panel Fabricator will Practice the Same 'THUMB RULE' method. The first iteration of my system used all 2/0 cabling between the big components such as between the battery and the shunt and fuse. JavaScript is disabled. Busbar Size Should be Equal or More than of 6300A. If you uncover any errors, mistakes, or otherwise inaccurate information, please let us know. Current density of 1 and 1.6 has to be selected for Aluminum and copper respectively. You are using an out of date browser. Send an email to info@bookofengineering.com. There are methods are exist in the world, To determine Proper sizing of Busbar for the Electrical Systems.

Sitemap 9

I want to learn how current capacity is decide based on cross section or dimensions or vise versa. thanking of you. thanks.

I want to learn how current capacity is decide based on cross section or dimensions or vise versa. thanking of you. thanks.  Limited Time Offer (expires soon): Save 15% on Pro Plan with code: NTX78. Consultant Recommended Busbar Size based on the 'THUMB Rule' We noticed, Busbar Size is Low to Carry 6300A.

Limited Time Offer (expires soon): Save 15% on Pro Plan with code: NTX78. Consultant Recommended Busbar Size based on the 'THUMB Rule' We noticed, Busbar Size is Low to Carry 6300A.  Hi, can you help me regarding how 1547A value came ? Please, how do i select the correct size of a bursar for my feeder panel. I'm running 8x230 cells in series, max continuous is .5 capacity, so 115A continuous if the battery is full capacity. Is it possible that it is for AC? and pls share the formula.

Hi, can you help me regarding how 1547A value came ? Please, how do i select the correct size of a bursar for my feeder panel. I'm running 8x230 cells in series, max continuous is .5 capacity, so 115A continuous if the battery is full capacity. Is it possible that it is for AC? and pls share the formula.  Thanks I would use existing bars and have a second battery in parallel. Comparing 'THREE', the most dangerous one is 'ACCIDENTAL'. Calculation as a whole is not having any clarity. Here it is not the case for the carrying Short Circuit Current. Consultant Challenged Contractor that, His recommended Size of Busbar will carry full load Current, then Contractor approached 'CPRI Testing for their internal verification.

Thanks I would use existing bars and have a second battery in parallel. Comparing 'THREE', the most dangerous one is 'ACCIDENTAL'. Calculation as a whole is not having any clarity. Here it is not the case for the carrying Short Circuit Current. Consultant Challenged Contractor that, His recommended Size of Busbar will carry full load Current, then Contractor approached 'CPRI Testing for their internal verification.  Here Electricity plays major role for the Fire Accident most of the Times. [Ex. Thanks for dropping by! I want to learn how current capacity is decide based on cross section or dimensions or vise versa. Generally there are 'THREE' Factors are involved for the Fire Causes.

Here Electricity plays major role for the Fire Accident most of the Times. [Ex. Thanks for dropping by! I want to learn how current capacity is decide based on cross section or dimensions or vise versa. Generally there are 'THREE' Factors are involved for the Fire Causes.  K3 is a Function of the Mounting Arrangement.

K3 is a Function of the Mounting Arrangement.  Panel Fabricators should not take responsible in case Panel gets fire due to the Busbar Under Sized. The Design Engineer should consider the following points while doing 'BUSBAR SIZING CALCULATION': Maximum Permissible Temperature Rise for bolt - connected devices, including busbars. This is anecdotal, so take it for what it's worth You must log in or register to reply here. Sol Ark: Ultimate Code Compliant Inverter, Grid Tie Solar Advisor (If you do not want to DIY your system, use this tool), Electrical: Busbar - DC Copper Busbar Ampacities, Busbar Current Calculator Online | Electrical4u, https://www.westmarine.com/WestAdvisor/Marine-Wire-Size-And-Ampacity, What Busbar size for 600A in 3P4S 816AH 12V, different sources different sizes and different ratings, 32x EVE LF280K pack configuration - need second/third opinion. That Source should be Top in the above list. Under Sized Cables]. To Carry the Current of 1067 A, One Run of 80 x 10 mm of Copper Bar is enough. e) POOR QUALITY IN DESIGNING.

Panel Fabricators should not take responsible in case Panel gets fire due to the Busbar Under Sized. The Design Engineer should consider the following points while doing 'BUSBAR SIZING CALCULATION': Maximum Permissible Temperature Rise for bolt - connected devices, including busbars. This is anecdotal, so take it for what it's worth You must log in or register to reply here. Sol Ark: Ultimate Code Compliant Inverter, Grid Tie Solar Advisor (If you do not want to DIY your system, use this tool), Electrical: Busbar - DC Copper Busbar Ampacities, Busbar Current Calculator Online | Electrical4u, https://www.westmarine.com/WestAdvisor/Marine-Wire-Size-And-Ampacity, What Busbar size for 600A in 3P4S 816AH 12V, different sources different sizes and different ratings, 32x EVE LF280K pack configuration - need second/third opinion. That Source should be Top in the above list. Under Sized Cables]. To Carry the Current of 1067 A, One Run of 80 x 10 mm of Copper Bar is enough. e) POOR QUALITY IN DESIGNING.  When are you visiting our place next? I'm noticing conflicting calculators (top 2 google results) and wondering if anyone can help explain the differences: The following tables have been provided by the Alliance for Telecommunications Industry Solutions (ATIS), T1 Committee, and represent ampacities for busbar sizes and arrangements typically found in the telecommunications industry. The Book Of Engineering material is copyrighted, however it is provided with NO WARRANTY or LIABILITY. People not have that much Patience for the Practicing Calculation. There are 'THREE' Elements must be present, for a 'FIRE' to initiate.

When are you visiting our place next? I'm noticing conflicting calculators (top 2 google results) and wondering if anyone can help explain the differences: The following tables have been provided by the Alliance for Telecommunications Industry Solutions (ATIS), T1 Committee, and represent ampacities for busbar sizes and arrangements typically found in the telecommunications industry. The Book Of Engineering material is copyrighted, however it is provided with NO WARRANTY or LIABILITY. People not have that much Patience for the Practicing Calculation. There are 'THREE' Elements must be present, for a 'FIRE' to initiate.  The content is copyrighted to EEP and may not be reproduced on other websites. Tell us what you're thinking. I want to connect the low voltage side of the transformer to a feeder panel with three busbars for the three phases and one bursbar for the Neutral that feeds risers. These are Oxygen, Fuel and Heat. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Sorry, preview is currently unavailable. The copper.com page specifically says it is for DC bus bars.

The content is copyrighted to EEP and may not be reproduced on other websites. Tell us what you're thinking. I want to connect the low voltage side of the transformer to a feeder panel with three busbars for the three phases and one bursbar for the Neutral that feeds risers. These are Oxygen, Fuel and Heat. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Sorry, preview is currently unavailable. The copper.com page specifically says it is for DC bus bars.  please explain in detail.

please explain in detail.

Thanks, this clears things up a bit. Avoidance of mechanical resonance under normal operating and Fault Conditions.

Thanks, this clears things up a bit. Avoidance of mechanical resonance under normal operating and Fault Conditions.  Bolting Arrangements for Continuous Busbar Connections. Then press the calculate button, you get the aluminium or copper busbar. 16S bank layout and bus bar sizing questions. +966-538436912. So, the bus bar 100x25x1.5 is suitable for =(100*25*1.5*0.8)=3000A incomer current. To view or add a comment, sign in

Bolting Arrangements for Continuous Busbar Connections. Then press the calculate button, you get the aluminium or copper busbar. 16S bank layout and bus bar sizing questions. +966-538436912. So, the bus bar 100x25x1.5 is suitable for =(100*25*1.5*0.8)=3000A incomer current. To view or add a comment, sign in  Can you please send to me the calculation of bus bar riser voltage drop. Thank you, je narrive pas tlcharger les fichiers excel.

Can you please send to me the calculation of bus bar riser voltage drop. Thank you, je narrive pas tlcharger les fichiers excel.  If we consider 80 x 10 mm of Copper Bar, How many bars required to carry full load current of Transformer Secondary End ?

If we consider 80 x 10 mm of Copper Bar, How many bars required to carry full load current of Transformer Secondary End ?  Selection of Adequate Busbar Insulator Standoffs. Correct if I am wrong. Study specialized LV/MV/HV technical articles and guides. Final calculation of current 1547 is confusing. Because some case people will add Tolerance in the Positive End.

Selection of Adequate Busbar Insulator Standoffs. Correct if I am wrong. Study specialized LV/MV/HV technical articles and guides. Final calculation of current 1547 is confusing. Because some case people will add Tolerance in the Positive End.  You can then calculate bus bar rating based on the total connected load supplied by the bus bar and rate you bus bar based on percentages of full load current of connected load. Enter the breadth and thickness of the busbar; do not enter the length of the busbar. You have 2500A, 2000A, 800A, 1500A, 600A, 250A, you size bus bar rating based on the three parameters total connected load of the system, fault level of the system, Do I have to subscribe to every download or technical article I need? What is the recommendable size of Copper Busbar in the LT Panel ?? A) copper.org uses Table 5 from ATIS Standard T1.311 and assumes a given temperature rise over ambient. Can u pl explain hot to calculate current rating of bus bar. we need excel sheet to calculate voltage drop in bus bar , kindly send me without protection.

You can then calculate bus bar rating based on the total connected load supplied by the bus bar and rate you bus bar based on percentages of full load current of connected load. Enter the breadth and thickness of the busbar; do not enter the length of the busbar. You have 2500A, 2000A, 800A, 1500A, 600A, 250A, you size bus bar rating based on the three parameters total connected load of the system, fault level of the system, Do I have to subscribe to every download or technical article I need? What is the recommendable size of Copper Busbar in the LT Panel ?? A) copper.org uses Table 5 from ATIS Standard T1.311 and assumes a given temperature rise over ambient. Can u pl explain hot to calculate current rating of bus bar. we need excel sheet to calculate voltage drop in bus bar , kindly send me without protection.

According to the Main Formula, Derived Value will be = 1547A???? Let's have a professional and meaningful conversation instead. Adaptive Relay Scheme with Dual Protection Techniques Based On Differential and Alienation Principles, Medium Voltage technical guide Technical collection Basics for MV cubicle design, Medium Voltage technical guide Basics for MV cubicle design, Power Systems Modelling and Fault Analysis..Theory and Practice-Nasser Tleis, Power Systems Modelling and Fault Analysis, Electrical network protection User's manual 06/2008 Sepam series 40, UNIT -II RECTIFIERS, FILTERS AND REGULATORS Introduction, Copper for Busbars Guidance for Design and Installation, TRANSMISSION & DISTRIBUTION OF ELECTRICAL POWER, DCS800 Hardware Manual DCS800 Drives (20 to 5200 A, TECHNICAL PERFORMANCE AND STABILITY ANALYSIS OF ESKOM POWER NETWORK USING 600KV, 800KV, AND 1000KV HVDC, Catalog HA 40 2 Switchgear Type 8DJH for Secondary Distribution Systems, KAUST Hotel VOLUME 3A (6 OF 6) ELECTRICAL SPECIFICATIONS SEPTEMBER 2017 CLIENT OPERATOR LEAD CONSULTANT INTERIOR CONSULTANT COST CONSULTANT, Shipboard Propulsion, Power Electronics, and Ocean Energy, introduction-to-instrumentation-and-measurements-2-edition-by-robert-b-northrop.pdf, Preface Introduction Quick Current Transformer, Short-Circuit Method IEC 61363 Technical Reference, Electrical installation guide 2009 According to IEC international standards Technical collection, Electrical installation guide According to IEC international standards Electrical installation guide, Catalog 2014 Electronic Products and Relays, Electrical installation guide 2013 According to IEC international standards, Instrumentation for Automation and Process Control for Engineers and Technicians, Electrical installation guide Schneider Electric Industries SAS Technical collection, Aircraft Electrical&Electronic Systems[Tooley], A compact frequency-domain photon migration system for integration into commercial hybrid small animal imaging scanners for fluorescence tomography, Influence of dc Component during Inadvertent Operation of the High Voltage Generator Circuit Breaker during Mis-Synchronization, Deflections of Reinforced Concrete Beams and Columns. According to the Formula as per IEC 62271 - I, According to the Main Formula, Derived Value will be = 1547A. Anything else apart from the Above,.Yes. for the Area 800 Sq.mm [80 x 10 mm], Current Carrying Capacity will be 960A.., Then additional one Run of Busbar needed to carry the Current of 1067A. in case of copper bus bar the current carrying capacity is 1.2(max). For a better experience, please enable JavaScript in your browser before proceeding. Copper.org's table is 30C over 40C ambient that's pretty darn hot! Hi. i.e They used 0.75 Amps / 1 Sq.mm of Bar & 1.4 Amps / 1 Sq.mm for Aluminium & Copper Respectively. aluminium bus bar current carrying capacity, aluminium busbar current rating calculation, busbar current carrying capacity calculator, copper busbar current carrying capacity calculator.

According to the Main Formula, Derived Value will be = 1547A???? Let's have a professional and meaningful conversation instead. Adaptive Relay Scheme with Dual Protection Techniques Based On Differential and Alienation Principles, Medium Voltage technical guide Technical collection Basics for MV cubicle design, Medium Voltage technical guide Basics for MV cubicle design, Power Systems Modelling and Fault Analysis..Theory and Practice-Nasser Tleis, Power Systems Modelling and Fault Analysis, Electrical network protection User's manual 06/2008 Sepam series 40, UNIT -II RECTIFIERS, FILTERS AND REGULATORS Introduction, Copper for Busbars Guidance for Design and Installation, TRANSMISSION & DISTRIBUTION OF ELECTRICAL POWER, DCS800 Hardware Manual DCS800 Drives (20 to 5200 A, TECHNICAL PERFORMANCE AND STABILITY ANALYSIS OF ESKOM POWER NETWORK USING 600KV, 800KV, AND 1000KV HVDC, Catalog HA 40 2 Switchgear Type 8DJH for Secondary Distribution Systems, KAUST Hotel VOLUME 3A (6 OF 6) ELECTRICAL SPECIFICATIONS SEPTEMBER 2017 CLIENT OPERATOR LEAD CONSULTANT INTERIOR CONSULTANT COST CONSULTANT, Shipboard Propulsion, Power Electronics, and Ocean Energy, introduction-to-instrumentation-and-measurements-2-edition-by-robert-b-northrop.pdf, Preface Introduction Quick Current Transformer, Short-Circuit Method IEC 61363 Technical Reference, Electrical installation guide 2009 According to IEC international standards Technical collection, Electrical installation guide According to IEC international standards Electrical installation guide, Catalog 2014 Electronic Products and Relays, Electrical installation guide 2013 According to IEC international standards, Instrumentation for Automation and Process Control for Engineers and Technicians, Electrical installation guide Schneider Electric Industries SAS Technical collection, Aircraft Electrical&Electronic Systems[Tooley], A compact frequency-domain photon migration system for integration into commercial hybrid small animal imaging scanners for fluorescence tomography, Influence of dc Component during Inadvertent Operation of the High Voltage Generator Circuit Breaker during Mis-Synchronization, Deflections of Reinforced Concrete Beams and Columns. According to the Formula as per IEC 62271 - I, According to the Main Formula, Derived Value will be = 1547A. Anything else apart from the Above,.Yes. for the Area 800 Sq.mm [80 x 10 mm], Current Carrying Capacity will be 960A.., Then additional one Run of Busbar needed to carry the Current of 1067A. in case of copper bus bar the current carrying capacity is 1.2(max). For a better experience, please enable JavaScript in your browser before proceeding. Copper.org's table is 30C over 40C ambient that's pretty darn hot! Hi. i.e They used 0.75 Amps / 1 Sq.mm of Bar & 1.4 Amps / 1 Sq.mm for Aluminium & Copper Respectively. aluminium bus bar current carrying capacity, aluminium busbar current rating calculation, busbar current carrying capacity calculator, copper busbar current carrying capacity calculator.  Now Software available to determine Proper Size of Busbar for the panels.

Now Software available to determine Proper Size of Busbar for the panels.  how you gets this value totally confusing, Hi All, 960A X 1.6 = 1536A for 2 Parallel Run. Good morning sir. Here I will like to describe Busbar Sizing of LT & HT Panel System. It seems authour not studied the related formula correctly. I guess it really comes down to heat and voltage loss then. Sometimes we didn't aware the bar Quality which is used by the fabricator in the Panel. So, please do not use a spammy keyword or a domain as your name, or it will be deleted. i want to determine the size of busbar i can use in the panel.

how you gets this value totally confusing, Hi All, 960A X 1.6 = 1536A for 2 Parallel Run. Good morning sir. Here I will like to describe Busbar Sizing of LT & HT Panel System. It seems authour not studied the related formula correctly. I guess it really comes down to heat and voltage loss then. Sometimes we didn't aware the bar Quality which is used by the fabricator in the Panel. So, please do not use a spammy keyword or a domain as your name, or it will be deleted. i want to determine the size of busbar i can use in the panel.  They are". For Copper:1.2 Amps / 1 Sq.mm of Copper. K4 is a Function of the Installed Location. Enter the email address you signed up with and we'll email you a reset link. [That Panel should cater 10 MW of Power of the IT Building, Panel gets power from 3 Transformers & 6 Generators]. SOURCES for the 'HEAT' in the 'ELECTRICAL SYSTEMS' : Most of the Time, Fire happens in the Electrical Panels, Which we observed from the Existing Cases. To view or add a comment, sign in. Adequate minimum required clearance between Phases and Phase to Earth. Normal loads will be more in the 70-90 range, but since I'm running a 3000W inverter I want to make sure my wiring is capable of at least 125A (24v) with some room for surge or accidental high loads. For Aluminium:0.7 Amps / 1 Sq.mm ofBar. hope everything is OK. It may not display this or other websites correctly. Thermal Effects on Busbar and Insulator Standoffs under normal and Fault conditions. So it is better to mention that, Sources for the 'HEAT' in the Electrical Panels.

They are". For Copper:1.2 Amps / 1 Sq.mm of Copper. K4 is a Function of the Installed Location. Enter the email address you signed up with and we'll email you a reset link. [That Panel should cater 10 MW of Power of the IT Building, Panel gets power from 3 Transformers & 6 Generators]. SOURCES for the 'HEAT' in the 'ELECTRICAL SYSTEMS' : Most of the Time, Fire happens in the Electrical Panels, Which we observed from the Existing Cases. To view or add a comment, sign in. Adequate minimum required clearance between Phases and Phase to Earth. Normal loads will be more in the 70-90 range, but since I'm running a 3000W inverter I want to make sure my wiring is capable of at least 125A (24v) with some room for surge or accidental high loads. For Aluminium:0.7 Amps / 1 Sq.mm ofBar. hope everything is OK. It may not display this or other websites correctly. Thermal Effects on Busbar and Insulator Standoffs under normal and Fault conditions. So it is better to mention that, Sources for the 'HEAT' in the Electrical Panels.  A 3000 watt inverter can draw up to ~150 service amps at 24 volts. The bus bar 100mm x25mm x1.5mm is suitable for incomer current =(100*25*1.5*1.2)=4500A. Ajay What is the parallel grouping factor for "N" no.of bus bars. You can download the paper by clicking the button above.

A 3000 watt inverter can draw up to ~150 service amps at 24 volts. The bus bar 100mm x25mm x1.5mm is suitable for incomer current =(100*25*1.5*1.2)=4500A. Ajay What is the parallel grouping factor for "N" no.of bus bars. You can download the paper by clicking the button above.  Panel should capable to Carry 6300A. please explain in detail. He should have to answer Client, Electrical Inspectorate & Consultant.

Panel should capable to Carry 6300A. please explain in detail. He should have to answer Client, Electrical Inspectorate & Consultant.  After that we will fabricate the Panel with Proper Sizing of busbar which we derived from the Proper Calculation. While This Methodology doesn't haveany relation with 'CALCULATION OF CONDUCTOR BUS SIZING [ACSR]' for the Switch yard Projects. Consultant given Busbar Size for the Main MV Panel. There is formula exist apart from the 'K' Factors. If Busbar doesn't able to carry the Full Load Current, then how it will carry Short Circuit Current for the Second.??? Pl share the main formula. In doing so, I decided to ditch the 2/0 cable where I could and use 150 amps out of 230 cells seems like a lot. K5 is a Function of any Artificial Ventilation.

After that we will fabricate the Panel with Proper Sizing of busbar which we derived from the Proper Calculation. While This Methodology doesn't haveany relation with 'CALCULATION OF CONDUCTOR BUS SIZING [ACSR]' for the Switch yard Projects. Consultant given Busbar Size for the Main MV Panel. There is formula exist apart from the 'K' Factors. If Busbar doesn't able to carry the Full Load Current, then how it will carry Short Circuit Current for the Second.??? Pl share the main formula. In doing so, I decided to ditch the 2/0 cable where I could and use 150 amps out of 230 cells seems like a lot. K5 is a Function of any Artificial Ventilation.  The Cost of the Aluminium bar in the Market based on the Quality. Solve some math:eighteen=nine. Ie. pouvez vous maider? Electricity Plays major role to provide 'HEAT' most of the Times. I'm trying to decide if I should build my own busbars (for higher ampacity) or if the bars that came with my 230AH cells are worth using. I have a transformer rated 500KVA 11kv/0.45kv. Can u pl explain to calculate current rating of bus bar. Prove that you are not R2-D2. Finally Busbar gets melted when it carried full load Current [6300A] for the interval 1 Minute. For 1067 A nominal current, we need 2 Parallel Bus Bars to be used. For Copper : 1.2 Amps / 1 Sq.mm of Copper. Does this 3000w 12v configuration work; and how should this kind of system be grounded? Calculate Bus Bar Size and Voltage Drop (Spreadsheet), Select Size of Bus Bar for particular Load, Enter Your Sub Panel Details like Load,Line Length.

The Cost of the Aluminium bar in the Market based on the Quality. Solve some math:eighteen=nine. Ie. pouvez vous maider? Electricity Plays major role to provide 'HEAT' most of the Times. I'm trying to decide if I should build my own busbars (for higher ampacity) or if the bars that came with my 230AH cells are worth using. I have a transformer rated 500KVA 11kv/0.45kv. Can u pl explain to calculate current rating of bus bar. Prove that you are not R2-D2. Finally Busbar gets melted when it carried full load Current [6300A] for the interval 1 Minute. For 1067 A nominal current, we need 2 Parallel Bus Bars to be used. For Copper : 1.2 Amps / 1 Sq.mm of Copper. Does this 3000w 12v configuration work; and how should this kind of system be grounded? Calculate Bus Bar Size and Voltage Drop (Spreadsheet), Select Size of Bus Bar for particular Load, Enter Your Sub Panel Details like Load,Line Length.  For Aluminium : 0.7 Amps / 1 Sq.mm of Bar. K2 is Corresponds to the Surface Finish of the Busbars. In some cases people only practicing Calculation with only consider the 'K' Factors. Transformer Rating : 11 / 0.433 kv, 800 kVA Transformer. Normally K factor together will come to .66 .. Please provide an example unable to understand that how to use..?? I would like to share one of the Example I experienced in my past. For the exact results please refer to your busbar providers data. We care about your opinion!

For Aluminium : 0.7 Amps / 1 Sq.mm of Bar. K2 is Corresponds to the Surface Finish of the Busbars. In some cases people only practicing Calculation with only consider the 'K' Factors. Transformer Rating : 11 / 0.433 kv, 800 kVA Transformer. Normally K factor together will come to .66 .. Please provide an example unable to understand that how to use..?? I would like to share one of the Example I experienced in my past. For the exact results please refer to your busbar providers data. We care about your opinion!  All applicable national and local legislation, standards and practices must be strictly followed and adhered to in this regard. Busbar Clearances as per IS : 4237 - 1967. Electrodynamic Forces applied to Busbars and Insulator Standoffs under Fault Conditions. Hi. This is a Parallel grouping factor . I hope the calculation result declared wrong.

All applicable national and local legislation, standards and practices must be strictly followed and adhered to in this regard. Busbar Clearances as per IS : 4237 - 1967. Electrodynamic Forces applied to Busbars and Insulator Standoffs under Fault Conditions. Hi. This is a Parallel grouping factor . I hope the calculation result declared wrong.

This Article Gives Clear Picture of 'BUSBAR SIZING CALCULATION' and What Care We should have to take 'Sizing of Busbar'. Hi Ajay, how things are moving there? Academia.edu no longer supports Internet Explorer. svp.

This Article Gives Clear Picture of 'BUSBAR SIZING CALCULATION' and What Care We should have to take 'Sizing of Busbar'. Hi Ajay, how things are moving there? Academia.edu no longer supports Internet Explorer. svp.  i want calculations for w x h x d ( 100 x 25 x 1.5 ) mm thick copper busbar. I would like to add more inputs in this article, which I had experienced in my past years. Please don't hesitate to send us an email or use our feedback form. You need to determine the faul level of the systems and full load current from the customer to determine the CB rating. It's highly advisable to double-check important information with other sources. Bus Bar rating are standard sizes based in iEC and IEEE. and pls share the formula. The 'Electrical Design Engineer' Should have in-depth knowledge of 'Sizing of BUSBAR for the Electrical Panels [Both HT & LT]. in case of aluminium bus bar the current carrying capacity is 0.8(max). This is an estimator for busbar current carrying capacity. thanking of you.

i want calculations for w x h x d ( 100 x 25 x 1.5 ) mm thick copper busbar. I would like to add more inputs in this article, which I had experienced in my past years. Please don't hesitate to send us an email or use our feedback form. You need to determine the faul level of the systems and full load current from the customer to determine the CB rating. It's highly advisable to double-check important information with other sources. Bus Bar rating are standard sizes based in iEC and IEEE. and pls share the formula. The 'Electrical Design Engineer' Should have in-depth knowledge of 'Sizing of BUSBAR for the Electrical Panels [Both HT & LT]. in case of aluminium bus bar the current carrying capacity is 0.8(max). This is an estimator for busbar current carrying capacity. thanking of you.  Both Calculations having different Steps & Procedure to find Final Results. Transformer Secondary Full load Current = 1066.72A, Breaker Size Needed = 1250A. Make it a point to visit Mysore and meet us. Here the above mentioned rules are not standard. Also 1547A figure to be replaced by 1536A. It will help you. I'm in the process of rearranging my system to make way for an inverter/charger upgrade. Please keep in mind that comments are moderated and rel="nofollow" is in use. Thanks for your quick response. The other site makes no mention of AC or DC. So People should take More Care for Busbar Sizing for both LT & HT Panels. where is from these informations? The Total 'K' Factor derived from Six 'K' factors, which is listed below : K1 is a Function of the Number of Bars per Phase and their space. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Get access to premium HV/MV/LV technical articles, advanced electrical engineering guides, papers, and much more! It will directly hit EPC Contractor Market Value in the Industry.Also it leads to Black Mark in their Industry. I have seen many times in my past experience, Most of the Engineers doing Busbar Sizing Calculation by 'Thumb Rule' Method, Even though Some of the Senior Engineers in the Consultant offices & Leading Panel Fabricator will Practice the Same 'THUMB RULE' method. The first iteration of my system used all 2/0 cabling between the big components such as between the battery and the shunt and fuse. JavaScript is disabled. Busbar Size Should be Equal or More than of 6300A. If you uncover any errors, mistakes, or otherwise inaccurate information, please let us know. Current density of 1 and 1.6 has to be selected for Aluminum and copper respectively. You are using an out of date browser. Send an email to info@bookofengineering.com. There are methods are exist in the world, To determine Proper sizing of Busbar for the Electrical Systems.

Both Calculations having different Steps & Procedure to find Final Results. Transformer Secondary Full load Current = 1066.72A, Breaker Size Needed = 1250A. Make it a point to visit Mysore and meet us. Here the above mentioned rules are not standard. Also 1547A figure to be replaced by 1536A. It will help you. I'm in the process of rearranging my system to make way for an inverter/charger upgrade. Please keep in mind that comments are moderated and rel="nofollow" is in use. Thanks for your quick response. The other site makes no mention of AC or DC. So People should take More Care for Busbar Sizing for both LT & HT Panels. where is from these informations? The Total 'K' Factor derived from Six 'K' factors, which is listed below : K1 is a Function of the Number of Bars per Phase and their space. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Get access to premium HV/MV/LV technical articles, advanced electrical engineering guides, papers, and much more! It will directly hit EPC Contractor Market Value in the Industry.Also it leads to Black Mark in their Industry. I have seen many times in my past experience, Most of the Engineers doing Busbar Sizing Calculation by 'Thumb Rule' Method, Even though Some of the Senior Engineers in the Consultant offices & Leading Panel Fabricator will Practice the Same 'THUMB RULE' method. The first iteration of my system used all 2/0 cabling between the big components such as between the battery and the shunt and fuse. JavaScript is disabled. Busbar Size Should be Equal or More than of 6300A. If you uncover any errors, mistakes, or otherwise inaccurate information, please let us know. Current density of 1 and 1.6 has to be selected for Aluminum and copper respectively. You are using an out of date browser. Send an email to info@bookofengineering.com. There are methods are exist in the world, To determine Proper sizing of Busbar for the Electrical Systems.