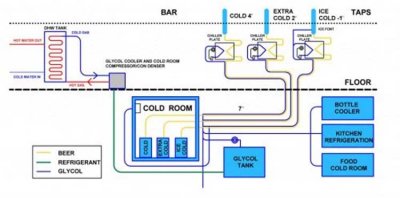

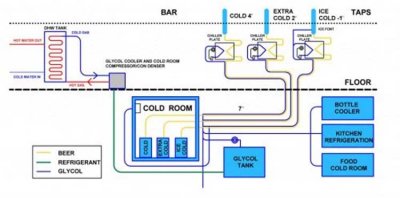

Glycol/water mixtures have a more moderate freezing point. Regardless of what you refer to this industry-changing system as, it offers the latest in beer dispensing & brewing technology keeping your draft beer flavorful and at the proper temperature from the brewery, to the refrigerator, to glass. We hope our guide will help you get your way around to this unique Do It Yourself project for your home breweries. For the best experience on our site, be sure to turn on Javascript in your browser. Each product line of the trunk line is hooked up to a unique beer keg stored in the walk-in cooler. - 300 Feet, Leaves the Warehouse in 7 to 10 business days, 12 Product /4 Glycol Trunk Line 5/16 I.D. Creating a good fitting housing, installing casters and handles will aid in maneuvering the whole thing around when connecting with the fermentors. The circulation pump runs continuously forcing the glycol through the supply line. This regulates temp and creates stable chemical reactions. If you want to extend the units lifespan, we advise you to use the purer waters. San Diego, CA 92126. Lead marketer, brewer, dad, and husband. This means the ideal chilled draft beer that will make your customers happy. To put it simply, the trunk line provides a sort of conduit of beer product lines connecting kegs of beer in the walk-in cooler to each respective faucet of the draft beer tower while also housing sealed refrigeration lines running from the power pack to the tower in a continuous loop. The price depends on the brand and specifications of each unit. For the best experience on our site, be sure to turn on Javascript in your browser. Flash chillers have an ice bath through which room temperature product circulates, exiting out the other side cooled to the desired service temperature. So how exactly does a glycol beer chiller work? Distilled, demineralized, and de-ionized water choices protect your units. Glycol power pack is the heart of the glycol tap system. Glycol draft beer system can stretch for up to 750 feet and feature up to 24 different products - and if youre looking for the best price on a glycol beer cooler, look no further than UBC Group USA.

The power pack is the heart of any glycol system, which is why you cant make any compromises when choosing one for your draft beer system. The ultimate goal of the whole glycol draft beer cooling system is to transport the beer from the walk-in cooler over a significant distance to the beer tower while maintaining a constant beer temperature of 36-38 degrees Fahrenheit (2-3 degrees Celsius). One may get intimidated by the idea of building ones own glycol chiller. These are manufactured specifically for engine cooling only. Apart from that, other equipment and materials like a jacketed vessel and coils are also needed to get the whole system running. We are competitively priced everyday but if you do find a better deal at another authorized dealer let us know. You will also need pumps, tubing, plywood, paint, insulation foam, and casters to assemble and keep the whole thing together. Get free standard shipping on thousands of designated products across our site. Draft beer tower - $100 - 2500 USD, 2014-2022 BeverageCraft Equipment Inc. All Rights Reserved, Glycol Draft Beer System Components and its Cost, Glycol reservoir with a coil (contains cooling refrigerant), outbound glycol line(s) (runs from the power pack to the tower), return glycol line(s) (enables the refrigerant to complete the cycle and become re-chilled). The trunk line contains up to four glycol lines: Refrigerant lines are there to keep all of the surrounding beer lines temperature-controlled from point A (storage) to point B (where the beer is dispensed). - 150 Feet, 10 Product /4 Glycol Trunk Line 3/8 I.D. Trust the experts at Refrigeration Plus for all of your Glycol chiller needs, especially during the brewing process. - 250 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. As for the installation, glycol draft beer lines are usually installed overhead or under the floor. After everything is placed accordingly in its position, fill the gaps with insulation foam to better control the temperature. As you may have noticed, prices are not immediately available on our website - to see them, all you need to do is create an account. All Rights Reserved, Glycol Cooled Beer Taps & Beer Dispensing Towers, MMPP4303-PKG Air Cooled Double Pump 3/4 HP Glycol Chiller | 11.5 Gal, 5100 BTUs, MMPP4302-PKG Air Cooled Double Pump 1/2 HP Glycol Chiller | 11.5 Gal, 3600 BTUs, MMPP4302 Air Cooled Single Pump 1/2 HP Glycol Chiller | 11.5 Gal, 3600 BTUs, MMPP4301 Air Cooled Single Pump 1/3 HP Glycol Chiller | 11.5 Gal, 2300 BTUs, MMPP4301-EP Air Cooled Single Pump 1/3 HP Glycol Chiller | 4.5 Gal, 2300 BTUs, 450' Run Glycol Beer Chiller System 3/4 HP | 18 Gallon | 2 Vane Pumps, 450' Run Glycol Beer Chiller System 3/4 HP | 18 Gallon | 1 Vane Pump, Special Offer - Aluminum Glycol Cooling Blocks, Set of 2, Glycol Beer Chiller System for Brewing & Fermentation Process | 3/4 HP, 12 Gal Tank | 220V, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/2 HP, 12 Gallon Tank, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/3 HP, 3 Gallon Tank, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/4 HP, 2.5 Gallon Tank, Glycol Chiller Digital Temperature Controller Kit, 25 Run Glycol Beer Chiller System 1/6 HP, 60' Run Glycol Beer Chiller System | 1/3 HP, 3 Gallon Tank. - 250 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. Forced-air systems work great but are often limited to shorter beer lines. With a hole saw and a jigsaw, cut holes at the top of your cooler for the glycol lines to run to the fermentors as well as exit the chiller. In this case, at a minimum, you should get an AC unit with 5,000 BTU/hr. Glycol beer systems that are properly designed, installed, maintained, and used properly work perfectly and waste little beer. The Yext script you entered is empty or incorrect: . A glycol/water solution gets to dissipate huge amounts of heat quickly. To put it simply, a long-draw system is designed for high-volume beer dispensing in that it depends on a walk-in cooler to store tapped kegs of beer, beer lines that run several feet, and a means of keeping the beer cold between the walk-in and the dispensing point. Glycol draft beer systems use

Making certain that your Glycol System stays at the proper operating temperature is one of the most important factors to guarantee that your final product keeps clients coming back for your brag worthy brews, as well as telling others about their superior experience. All Draught Beer Dispense System Components, Glycol Power Pack, Extra-1.5P Water Cooled. Rapids is here to help you determine the size Glycol Chiller and setup you will need to serve your beer cold from the keg. Flash chilling involves chilling the beer at the point of service. Who knows, you might surprise yourself! When installed under the floor, the product lines are run through a section of PVC tubing. - 200 Feet, 8 Product /2 Glycol Trunk Line 3/8 I.D. Subscribe now for coupons, exclusive deals, and design inspiration! I would had like to have known that it did not come with with glycol. propylene glycol as the cooling agent (hence, the name). Although glycol-cooled draft beer systems consist of dozens of components, the three main ones will always be these: Now, lets examine each one of these components and see what their role in the process is. This particular chemical removes the excess heat produced from the process of brewing beer, then breaks off this heat to the refrigeration system. Well make sure that your Glycol System stays at the optimal operating temperature from start to finish, leaving you with a distinctly flavorsome final product. This should also be tested from time to time to avoid any contaminations or corrosion issues. Do you have all the materials listed above? Choose from a wide range of glycol chillers, glycol units, trunk lines for glycol systems, beer switches, wall brackets and splitters, pumps and motors, glycol-line installation kits, all at competitive prices! Newer Post , Please note, comments must be approved before they are published, EG-3/4P Glycol chiller - I am using this chiller for my WHITE and ROSE wines. All you have to do then is pull the lever called tap handle and pour some fresh, cold beer. There are various methods to undertake this cooling and the two most popular and accessible methods for chilling beer are glycol cooling and flash chilling.

A flash chiller can also be added to a long-draw, glycol cooler system to provide extra cooling. This step could be irreparable! And when is a flash chiller better than a glycol cooling system? Use a pump in the cooler to help recirculate the glycols on the evaporator when the AC unit is switched on. Thus, it is often preferred by breweries. - 250 Feet, 8 Product /2 Glycol Trunk Line 5/16 I.D. - 150 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. Lower budget Coleman beer coolers are often preferred. Enclosing one makes it look cleaner too. Go with UBC Group USA and you will get the right quality at the right price. Take it out to create a better working space.

Brewers mix a percentage of glycol and water for better outcomes and lowered costs. There are many names for the Glycol system such as glycol beer cooling systems, glycol beer dispensing systems, glycol beer systems, or glycol chillers. All rights reserved. Outstanding insulation. This avoids unnecessary heating to your home. If youre a brewery owner, youve already discovered the benefits of the glycol cooling system throughout your brewing process and realize that it is critical to product outcome. From basic hp models for small bars to powerful 1 monsters capable of serving glycol cooled draft beer systems stretching for up to 750 feet, we have it all. - 300 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. Looking for Glycol Cooled Beer Taps & Beer Dispensing Towers? - 300 Feet, 12 Product /4 Glycol Trunk Line 3/8 I.D. Refrigeration Pluss highly trained technicians take care of all of your tap beer and brewery glycol cooling concerns, from our regular maintenance service to essential repairs. CO2 & Nitrogen cylinders - $65-80 USD, 2. For more details, see price match policy. - 250 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. The evaporator has a fan that will be of no use. Watch how moving a piece at a time affects another piece of copper. We want to make sure there are no problems with the tubing, as copper bends quite easily. JavaScript seems to be disabled in your browser.

Glycol itself is a colorless, odorless, slightly syrupy chemical compound that is a bit thicker than water. This makes sure you dont shock your beer when it starts to cool.

For cold crashing, use temp of -1/-2C. We stand by our high-quality products and are committed to long-term customer satisfaction. - 150 Feet, 12 Product /4 Glycol Trunk Line 3/8 I.D.

Wrap the glycol hoses with insulation foam to prevent sweating. - 150 Feet, 4 Product /2 Glycol Trunk Line 5/16 I.D. This unit is an essential component of a glycol draft beer dispensing system - in this system, you have your beer delivered to the tower via a trunk line. Free 25 Homebrewing Hacks E-book Download. Get the best performing 120 coil jockey boxes while paying the price of 70.

Step 7: Load your glycol and water mixture. Make sure to vent the heat from the AC unit in use outside your working space. Glycol is a non-evaporating refrigeration liquid. Never use automotive anti-freeze chemicals. - 200 Feet, 6 Product /2 Glycol Trunk Line 3/8 I.D. - 300 Feet, 6 Product /2 Glycol Trunk Line 5/16 I.D. Most systems just use tap waters. Here are 8 steps to making your own glycol chillers at home: Remove the AC unit outer casing where you will find the evaporator and condenser exposed. If they are installed overhead, the exposed downward trunk lines would be generally housed in a combination of PVC tubing and a decorative finish.

Special cooling systems that use food-grade propylene glycol as an anti-freeze agent. Please choose from the available languages below: JULY SAVINGS | Save Big On All Deals! 1.

In a glycol cooler system, beer passes through tubes to a chiller plate and becomes cold. The assembly of product lines and glycol lines is wrapped in a shield of foam and encased in a plastic waterproof jacket. The trunk line itself is a bunch of beer lines (usually, from 4 to 10) sandwiched around a pair of glycol refrigeration lines all of which are wrapped in foil and bound together with some insulation on top. We have been a reliable supplier of glycol chillers for beer wholesale and other types of commercial beverage equipment for over a decade and are always striving to provide the best conditions for our customers. - 300 Feet, 12 Product /4 Glycol Trunk Line 3/8 I.D. JavaScript seems to be disabled in your browser. We usually ship our products within 24 hours of order placement through the best available method, depending on the product and destination - either via UPS (smaller items) or freight carrier (for large/heavy items). Consider your local environmental rules and regulations with regard to antifreeze solutions. A portable type AC unit is preferred because they have exhaust hoses that allow you to draw the heat produced out to your window. | Sitemap, kegs do undergo faster flavor degradation the higher the storage temperature, The Benefits of Early CO2 Leak Detection in Breweries, Bars and Restaurants, The Importance of CO2 Safety in Breweries, Bars and Restaurants, Preferred Line Cleaning Method: Electric Re-circulation Pump. This system is mainly used for long-draw beer dispensing setups (typically, running 25 ft or longer). The price was fair. -250 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D.

KegLand Distribution PTY LTD,410 Princes Hwy,Noble Park North,Victoria,3174,Australia. On the fermentors, establish tubing connectors too. beer kegs in a walk-in cooler thats located far from the bar counter where beer is actually dispensed. 99% of Draft beer must be served cold! Use your temperature controller to set up your units temps. Primarygas regulators - $30-70 USD, 5. I dont know about you, but a nice cold beer on a warm summers day is one of the best things in life! Propylene glycols freezing point is at -74.2F or -59C. Rapids carries the best selectiion of quality Glycol Chillers in a varitety of sizes to best suit your needs. If you hear any unusual hissing signifying any broken parts or a leaking refrigerant, take the unit outside your house and call a professional.

Go for 25% and above glycols.

Proportions will depend on your preference and testing.

The compressor runs on and off as necessary to maintain the temperature thats been set on the thermostat.

The kegs are connected to CO2 or nitrogen cylinders through a series of gas blenders and pressure regulators. The ice bath is kept cooler than the desired temperature of the product so as to ensure efficient chilling. Now that we got the main idea of a glycol beer line cooling system, lets take a look at its components and see how it all works. We suggest you to test the waters first and see where it goes. But when should you install a glycol system over a flash chilling system? Get all the equipment that you need to create and assemble the ideal glycol-cooling system for your bar, restaurant, pub, or tavern so your customers and patrons can enjoy a perfectly chilled mug of draft beer. Keeping your Glycol cooling system properly maintained on a regular basis reduces your overall maintenance costs.

Glycol cooling involves wrapping all of your beer lines in an insulated trunk line between your keg cooler and your beer tower. This is a placeholder for the Yext Knolwedge Tags. Most items can be returned up to 30 days from the purchase date. Do not remove this. Beer lines are attached to a shank or faucet thats inside the beer tower. - 200 Feet, 10 Product /4 Glycol Trunk Line 3/8 I.D. - 300 Feet, 2 Product /2 Glycol Trunk Line 3/8 I.D. This will avoid sweating, provide better stability for the structures, and in essence, extend the lifespan of your unit. Structure, drainage, and disposal are some to prepare for properly. Just give us a call to return your item. We provide a variety of equipment and parts for anyone looking to assemble the perfect glycol beer chiller for their bar, tavern, pub, restaurant, or any other facility. Commercial Bar Accessories and Parts (117), Commercial Refrigeration Accessories and Parts (1). Some items, like very large and heavy products, do not qualify at this time. EG-3/4P Glycol chiller - This unit came with in a resable time, Good looking unit , Works very well and easy to install. We recommend glycol-cooled draft beer systems for those looking for longer beer runs for their tavern, pub, or bar. - 125 Feet. Keep your beer and other beverages cold with our awesome selection of Glycol Chillers. Older Post These are the fermentors, glycol lines, and cooler. - 300 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. The size will depend on the quantity of the brew batch you need to cool. The power pack pushes refrigeration (glycol) through the center of the trunk line. All Rights Reserved, Glycol Cooled Beer Taps & Beer Dispensing Towers, Gear Driven Pump for BVL Glycol Beer Chillers, Stainless Steel U Bend Fitting for 3/8" ID Beer Tubing, American Beverage Procon Glycol Recirculating Pump, Shurflo Beer-Ace Gas Pump System for Beer Carbonation, 5 Gallon 100% Glycol Solution for Beer Chiller System, 90' Run Glycol Beer Chiller System | 1/3 HP, 4 Gallon Tank, 25 Run Glycol Beer Chiller System 1/6 HP. Youll find a glycol cooler useful with worts, brite tanks, fermenters, and heat exchangers.

In this article, we talk about its main components, how they work, and how much they cost.

Glycol cooling systems, on the other hand, work well at greater distances and are excellent for beer lines that run up to twenty-five feet or more. We use encrypted SSL security to ensure that your credit card information is always protected. The chilling process works by forcing a cold liquid (glycol) along tubes to a chiller plate, which is usually cast aluminum, and then through the tap system, thereby keeping the beer cold. - 250 Feet, 6 Product /2 Glycol Trunk Line 3/8 I.D.

Many of our expert Sales Representatives have years of experience in the food-service and beer industries before coming to join us. These are the parts necessary for the movement of heat. This could be very flammable and dangerous to your health once inhaled. For the best experience on our site, be sure to turn on Javascript in your browser. Glycol can lower the freezing point, while water can keep heat capacities high enough out of the fermentors to function efficiently. Would buy again and recommend to everyone. The idea behind a glycol beer line cooler is simple - when the distance between the beer keg cooler (where beer is stored) and the draft beer tower (where beer is dispensed) is longer than 25 feet, chances are you will get foam in your beer - it gets warm too soon, before reaching the tower. It may not be as easy peasy, but it can save you a lot of bucks and time.

Looking for something specific that you didnt find on our website? Trust the experience and industry expertise of Rapids to help you set up your long draw beer cooling system when your serving beer in a different place than your kegs are stored. -150 Feet, 8 Product /2 Glycol Trunk Line 5/16 I.D.

Sitemap 10

The power pack is the heart of any glycol system, which is why you cant make any compromises when choosing one for your draft beer system. The ultimate goal of the whole glycol draft beer cooling system is to transport the beer from the walk-in cooler over a significant distance to the beer tower while maintaining a constant beer temperature of 36-38 degrees Fahrenheit (2-3 degrees Celsius). One may get intimidated by the idea of building ones own glycol chiller. These are manufactured specifically for engine cooling only. Apart from that, other equipment and materials like a jacketed vessel and coils are also needed to get the whole system running. We are competitively priced everyday but if you do find a better deal at another authorized dealer let us know. You will also need pumps, tubing, plywood, paint, insulation foam, and casters to assemble and keep the whole thing together. Get free standard shipping on thousands of designated products across our site. Draft beer tower - $100 - 2500 USD, 2014-2022 BeverageCraft Equipment Inc. All Rights Reserved, Glycol Draft Beer System Components and its Cost, Glycol reservoir with a coil (contains cooling refrigerant), outbound glycol line(s) (runs from the power pack to the tower), return glycol line(s) (enables the refrigerant to complete the cycle and become re-chilled). The trunk line contains up to four glycol lines: Refrigerant lines are there to keep all of the surrounding beer lines temperature-controlled from point A (storage) to point B (where the beer is dispensed). - 150 Feet, 10 Product /4 Glycol Trunk Line 3/8 I.D. Trust the experts at Refrigeration Plus for all of your Glycol chiller needs, especially during the brewing process. - 250 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. As for the installation, glycol draft beer lines are usually installed overhead or under the floor. After everything is placed accordingly in its position, fill the gaps with insulation foam to better control the temperature. As you may have noticed, prices are not immediately available on our website - to see them, all you need to do is create an account. All Rights Reserved, Glycol Cooled Beer Taps & Beer Dispensing Towers, MMPP4303-PKG Air Cooled Double Pump 3/4 HP Glycol Chiller | 11.5 Gal, 5100 BTUs, MMPP4302-PKG Air Cooled Double Pump 1/2 HP Glycol Chiller | 11.5 Gal, 3600 BTUs, MMPP4302 Air Cooled Single Pump 1/2 HP Glycol Chiller | 11.5 Gal, 3600 BTUs, MMPP4301 Air Cooled Single Pump 1/3 HP Glycol Chiller | 11.5 Gal, 2300 BTUs, MMPP4301-EP Air Cooled Single Pump 1/3 HP Glycol Chiller | 4.5 Gal, 2300 BTUs, 450' Run Glycol Beer Chiller System 3/4 HP | 18 Gallon | 2 Vane Pumps, 450' Run Glycol Beer Chiller System 3/4 HP | 18 Gallon | 1 Vane Pump, Special Offer - Aluminum Glycol Cooling Blocks, Set of 2, Glycol Beer Chiller System for Brewing & Fermentation Process | 3/4 HP, 12 Gal Tank | 220V, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/2 HP, 12 Gallon Tank, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/3 HP, 3 Gallon Tank, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/4 HP, 2.5 Gallon Tank, Glycol Chiller Digital Temperature Controller Kit, 25 Run Glycol Beer Chiller System 1/6 HP, 60' Run Glycol Beer Chiller System | 1/3 HP, 3 Gallon Tank. - 250 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. Forced-air systems work great but are often limited to shorter beer lines. With a hole saw and a jigsaw, cut holes at the top of your cooler for the glycol lines to run to the fermentors as well as exit the chiller. In this case, at a minimum, you should get an AC unit with 5,000 BTU/hr. Glycol beer systems that are properly designed, installed, maintained, and used properly work perfectly and waste little beer. The Yext script you entered is empty or incorrect: . A glycol/water solution gets to dissipate huge amounts of heat quickly. To put it simply, a long-draw system is designed for high-volume beer dispensing in that it depends on a walk-in cooler to store tapped kegs of beer, beer lines that run several feet, and a means of keeping the beer cold between the walk-in and the dispensing point. Glycol draft beer systems use

Making certain that your Glycol System stays at the proper operating temperature is one of the most important factors to guarantee that your final product keeps clients coming back for your brag worthy brews, as well as telling others about their superior experience. All Draught Beer Dispense System Components, Glycol Power Pack, Extra-1.5P Water Cooled. Rapids is here to help you determine the size Glycol Chiller and setup you will need to serve your beer cold from the keg. Flash chilling involves chilling the beer at the point of service. Who knows, you might surprise yourself! When installed under the floor, the product lines are run through a section of PVC tubing. - 200 Feet, 8 Product /2 Glycol Trunk Line 3/8 I.D. Subscribe now for coupons, exclusive deals, and design inspiration! I would had like to have known that it did not come with with glycol. propylene glycol as the cooling agent (hence, the name). Although glycol-cooled draft beer systems consist of dozens of components, the three main ones will always be these: Now, lets examine each one of these components and see what their role in the process is. This particular chemical removes the excess heat produced from the process of brewing beer, then breaks off this heat to the refrigeration system. Well make sure that your Glycol System stays at the optimal operating temperature from start to finish, leaving you with a distinctly flavorsome final product. This should also be tested from time to time to avoid any contaminations or corrosion issues. Do you have all the materials listed above? Choose from a wide range of glycol chillers, glycol units, trunk lines for glycol systems, beer switches, wall brackets and splitters, pumps and motors, glycol-line installation kits, all at competitive prices! Newer Post , Please note, comments must be approved before they are published, EG-3/4P Glycol chiller - I am using this chiller for my WHITE and ROSE wines. All you have to do then is pull the lever called tap handle and pour some fresh, cold beer. There are various methods to undertake this cooling and the two most popular and accessible methods for chilling beer are glycol cooling and flash chilling.

The power pack is the heart of any glycol system, which is why you cant make any compromises when choosing one for your draft beer system. The ultimate goal of the whole glycol draft beer cooling system is to transport the beer from the walk-in cooler over a significant distance to the beer tower while maintaining a constant beer temperature of 36-38 degrees Fahrenheit (2-3 degrees Celsius). One may get intimidated by the idea of building ones own glycol chiller. These are manufactured specifically for engine cooling only. Apart from that, other equipment and materials like a jacketed vessel and coils are also needed to get the whole system running. We are competitively priced everyday but if you do find a better deal at another authorized dealer let us know. You will also need pumps, tubing, plywood, paint, insulation foam, and casters to assemble and keep the whole thing together. Get free standard shipping on thousands of designated products across our site. Draft beer tower - $100 - 2500 USD, 2014-2022 BeverageCraft Equipment Inc. All Rights Reserved, Glycol Draft Beer System Components and its Cost, Glycol reservoir with a coil (contains cooling refrigerant), outbound glycol line(s) (runs from the power pack to the tower), return glycol line(s) (enables the refrigerant to complete the cycle and become re-chilled). The trunk line contains up to four glycol lines: Refrigerant lines are there to keep all of the surrounding beer lines temperature-controlled from point A (storage) to point B (where the beer is dispensed). - 150 Feet, 10 Product /4 Glycol Trunk Line 3/8 I.D. Trust the experts at Refrigeration Plus for all of your Glycol chiller needs, especially during the brewing process. - 250 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. As for the installation, glycol draft beer lines are usually installed overhead or under the floor. After everything is placed accordingly in its position, fill the gaps with insulation foam to better control the temperature. As you may have noticed, prices are not immediately available on our website - to see them, all you need to do is create an account. All Rights Reserved, Glycol Cooled Beer Taps & Beer Dispensing Towers, MMPP4303-PKG Air Cooled Double Pump 3/4 HP Glycol Chiller | 11.5 Gal, 5100 BTUs, MMPP4302-PKG Air Cooled Double Pump 1/2 HP Glycol Chiller | 11.5 Gal, 3600 BTUs, MMPP4302 Air Cooled Single Pump 1/2 HP Glycol Chiller | 11.5 Gal, 3600 BTUs, MMPP4301 Air Cooled Single Pump 1/3 HP Glycol Chiller | 11.5 Gal, 2300 BTUs, MMPP4301-EP Air Cooled Single Pump 1/3 HP Glycol Chiller | 4.5 Gal, 2300 BTUs, 450' Run Glycol Beer Chiller System 3/4 HP | 18 Gallon | 2 Vane Pumps, 450' Run Glycol Beer Chiller System 3/4 HP | 18 Gallon | 1 Vane Pump, Special Offer - Aluminum Glycol Cooling Blocks, Set of 2, Glycol Beer Chiller System for Brewing & Fermentation Process | 3/4 HP, 12 Gal Tank | 220V, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/2 HP, 12 Gallon Tank, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/3 HP, 3 Gallon Tank, Glycol Beer Chiller System for Brewing & Fermentation Process | 1/4 HP, 2.5 Gallon Tank, Glycol Chiller Digital Temperature Controller Kit, 25 Run Glycol Beer Chiller System 1/6 HP, 60' Run Glycol Beer Chiller System | 1/3 HP, 3 Gallon Tank. - 250 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. Forced-air systems work great but are often limited to shorter beer lines. With a hole saw and a jigsaw, cut holes at the top of your cooler for the glycol lines to run to the fermentors as well as exit the chiller. In this case, at a minimum, you should get an AC unit with 5,000 BTU/hr. Glycol beer systems that are properly designed, installed, maintained, and used properly work perfectly and waste little beer. The Yext script you entered is empty or incorrect: . A glycol/water solution gets to dissipate huge amounts of heat quickly. To put it simply, a long-draw system is designed for high-volume beer dispensing in that it depends on a walk-in cooler to store tapped kegs of beer, beer lines that run several feet, and a means of keeping the beer cold between the walk-in and the dispensing point. Glycol draft beer systems use

Making certain that your Glycol System stays at the proper operating temperature is one of the most important factors to guarantee that your final product keeps clients coming back for your brag worthy brews, as well as telling others about their superior experience. All Draught Beer Dispense System Components, Glycol Power Pack, Extra-1.5P Water Cooled. Rapids is here to help you determine the size Glycol Chiller and setup you will need to serve your beer cold from the keg. Flash chilling involves chilling the beer at the point of service. Who knows, you might surprise yourself! When installed under the floor, the product lines are run through a section of PVC tubing. - 200 Feet, 8 Product /2 Glycol Trunk Line 3/8 I.D. Subscribe now for coupons, exclusive deals, and design inspiration! I would had like to have known that it did not come with with glycol. propylene glycol as the cooling agent (hence, the name). Although glycol-cooled draft beer systems consist of dozens of components, the three main ones will always be these: Now, lets examine each one of these components and see what their role in the process is. This particular chemical removes the excess heat produced from the process of brewing beer, then breaks off this heat to the refrigeration system. Well make sure that your Glycol System stays at the optimal operating temperature from start to finish, leaving you with a distinctly flavorsome final product. This should also be tested from time to time to avoid any contaminations or corrosion issues. Do you have all the materials listed above? Choose from a wide range of glycol chillers, glycol units, trunk lines for glycol systems, beer switches, wall brackets and splitters, pumps and motors, glycol-line installation kits, all at competitive prices! Newer Post , Please note, comments must be approved before they are published, EG-3/4P Glycol chiller - I am using this chiller for my WHITE and ROSE wines. All you have to do then is pull the lever called tap handle and pour some fresh, cold beer. There are various methods to undertake this cooling and the two most popular and accessible methods for chilling beer are glycol cooling and flash chilling.  A flash chiller can also be added to a long-draw, glycol cooler system to provide extra cooling. This step could be irreparable! And when is a flash chiller better than a glycol cooling system? Use a pump in the cooler to help recirculate the glycols on the evaporator when the AC unit is switched on. Thus, it is often preferred by breweries. - 250 Feet, 8 Product /2 Glycol Trunk Line 5/16 I.D. - 150 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. Lower budget Coleman beer coolers are often preferred. Enclosing one makes it look cleaner too. Go with UBC Group USA and you will get the right quality at the right price. Take it out to create a better working space.

A flash chiller can also be added to a long-draw, glycol cooler system to provide extra cooling. This step could be irreparable! And when is a flash chiller better than a glycol cooling system? Use a pump in the cooler to help recirculate the glycols on the evaporator when the AC unit is switched on. Thus, it is often preferred by breweries. - 250 Feet, 8 Product /2 Glycol Trunk Line 5/16 I.D. - 150 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. Lower budget Coleman beer coolers are often preferred. Enclosing one makes it look cleaner too. Go with UBC Group USA and you will get the right quality at the right price. Take it out to create a better working space.  Brewers mix a percentage of glycol and water for better outcomes and lowered costs. There are many names for the Glycol system such as glycol beer cooling systems, glycol beer dispensing systems, glycol beer systems, or glycol chillers. All rights reserved. Outstanding insulation. This avoids unnecessary heating to your home. If youre a brewery owner, youve already discovered the benefits of the glycol cooling system throughout your brewing process and realize that it is critical to product outcome. From basic hp models for small bars to powerful 1 monsters capable of serving glycol cooled draft beer systems stretching for up to 750 feet, we have it all. - 300 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. Looking for Glycol Cooled Beer Taps & Beer Dispensing Towers? - 300 Feet, 12 Product /4 Glycol Trunk Line 3/8 I.D. Refrigeration Pluss highly trained technicians take care of all of your tap beer and brewery glycol cooling concerns, from our regular maintenance service to essential repairs. CO2 & Nitrogen cylinders - $65-80 USD, 2. For more details, see price match policy. - 250 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. The evaporator has a fan that will be of no use. Watch how moving a piece at a time affects another piece of copper. We want to make sure there are no problems with the tubing, as copper bends quite easily. JavaScript seems to be disabled in your browser.

Brewers mix a percentage of glycol and water for better outcomes and lowered costs. There are many names for the Glycol system such as glycol beer cooling systems, glycol beer dispensing systems, glycol beer systems, or glycol chillers. All rights reserved. Outstanding insulation. This avoids unnecessary heating to your home. If youre a brewery owner, youve already discovered the benefits of the glycol cooling system throughout your brewing process and realize that it is critical to product outcome. From basic hp models for small bars to powerful 1 monsters capable of serving glycol cooled draft beer systems stretching for up to 750 feet, we have it all. - 300 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. Looking for Glycol Cooled Beer Taps & Beer Dispensing Towers? - 300 Feet, 12 Product /4 Glycol Trunk Line 3/8 I.D. Refrigeration Pluss highly trained technicians take care of all of your tap beer and brewery glycol cooling concerns, from our regular maintenance service to essential repairs. CO2 & Nitrogen cylinders - $65-80 USD, 2. For more details, see price match policy. - 250 Feet, 10 Product /4 Glycol Trunk Line 5/16 I.D. The evaporator has a fan that will be of no use. Watch how moving a piece at a time affects another piece of copper. We want to make sure there are no problems with the tubing, as copper bends quite easily. JavaScript seems to be disabled in your browser.  Glycol itself is a colorless, odorless, slightly syrupy chemical compound that is a bit thicker than water. This makes sure you dont shock your beer when it starts to cool.

Glycol itself is a colorless, odorless, slightly syrupy chemical compound that is a bit thicker than water. This makes sure you dont shock your beer when it starts to cool.  For cold crashing, use temp of -1/-2C. We stand by our high-quality products and are committed to long-term customer satisfaction. - 150 Feet, 12 Product /4 Glycol Trunk Line 3/8 I.D.

For cold crashing, use temp of -1/-2C. We stand by our high-quality products and are committed to long-term customer satisfaction. - 150 Feet, 12 Product /4 Glycol Trunk Line 3/8 I.D.  Wrap the glycol hoses with insulation foam to prevent sweating. - 150 Feet, 4 Product /2 Glycol Trunk Line 5/16 I.D. This unit is an essential component of a glycol draft beer dispensing system - in this system, you have your beer delivered to the tower via a trunk line. Free 25 Homebrewing Hacks E-book Download. Get the best performing 120 coil jockey boxes while paying the price of 70.

Wrap the glycol hoses with insulation foam to prevent sweating. - 150 Feet, 4 Product /2 Glycol Trunk Line 5/16 I.D. This unit is an essential component of a glycol draft beer dispensing system - in this system, you have your beer delivered to the tower via a trunk line. Free 25 Homebrewing Hacks E-book Download. Get the best performing 120 coil jockey boxes while paying the price of 70.  Step 7: Load your glycol and water mixture. Make sure to vent the heat from the AC unit in use outside your working space. Glycol is a non-evaporating refrigeration liquid. Never use automotive anti-freeze chemicals. - 200 Feet, 6 Product /2 Glycol Trunk Line 3/8 I.D. - 300 Feet, 6 Product /2 Glycol Trunk Line 5/16 I.D. Most systems just use tap waters. Here are 8 steps to making your own glycol chillers at home: Remove the AC unit outer casing where you will find the evaporator and condenser exposed. If they are installed overhead, the exposed downward trunk lines would be generally housed in a combination of PVC tubing and a decorative finish.

Step 7: Load your glycol and water mixture. Make sure to vent the heat from the AC unit in use outside your working space. Glycol is a non-evaporating refrigeration liquid. Never use automotive anti-freeze chemicals. - 200 Feet, 6 Product /2 Glycol Trunk Line 3/8 I.D. - 300 Feet, 6 Product /2 Glycol Trunk Line 5/16 I.D. Most systems just use tap waters. Here are 8 steps to making your own glycol chillers at home: Remove the AC unit outer casing where you will find the evaporator and condenser exposed. If they are installed overhead, the exposed downward trunk lines would be generally housed in a combination of PVC tubing and a decorative finish.  Special cooling systems that use food-grade propylene glycol as an anti-freeze agent. Please choose from the available languages below: JULY SAVINGS | Save Big On All Deals! 1.

Special cooling systems that use food-grade propylene glycol as an anti-freeze agent. Please choose from the available languages below: JULY SAVINGS | Save Big On All Deals! 1.  KegLand Distribution PTY LTD,410 Princes Hwy,Noble Park North,Victoria,3174,Australia. On the fermentors, establish tubing connectors too. beer kegs in a walk-in cooler thats located far from the bar counter where beer is actually dispensed. 99% of Draft beer must be served cold! Use your temperature controller to set up your units temps. Primarygas regulators - $30-70 USD, 5. I dont know about you, but a nice cold beer on a warm summers day is one of the best things in life! Propylene glycols freezing point is at -74.2F or -59C. Rapids carries the best selectiion of quality Glycol Chillers in a varitety of sizes to best suit your needs. If you hear any unusual hissing signifying any broken parts or a leaking refrigerant, take the unit outside your house and call a professional.

KegLand Distribution PTY LTD,410 Princes Hwy,Noble Park North,Victoria,3174,Australia. On the fermentors, establish tubing connectors too. beer kegs in a walk-in cooler thats located far from the bar counter where beer is actually dispensed. 99% of Draft beer must be served cold! Use your temperature controller to set up your units temps. Primarygas regulators - $30-70 USD, 5. I dont know about you, but a nice cold beer on a warm summers day is one of the best things in life! Propylene glycols freezing point is at -74.2F or -59C. Rapids carries the best selectiion of quality Glycol Chillers in a varitety of sizes to best suit your needs. If you hear any unusual hissing signifying any broken parts or a leaking refrigerant, take the unit outside your house and call a professional.  Go for 25% and above glycols.

Go for 25% and above glycols.  Proportions will depend on your preference and testing.

Proportions will depend on your preference and testing.  The compressor runs on and off as necessary to maintain the temperature thats been set on the thermostat.

The compressor runs on and off as necessary to maintain the temperature thats been set on the thermostat.  The kegs are connected to CO2 or nitrogen cylinders through a series of gas blenders and pressure regulators. The ice bath is kept cooler than the desired temperature of the product so as to ensure efficient chilling. Now that we got the main idea of a glycol beer line cooling system, lets take a look at its components and see how it all works. We suggest you to test the waters first and see where it goes. But when should you install a glycol system over a flash chilling system? Get all the equipment that you need to create and assemble the ideal glycol-cooling system for your bar, restaurant, pub, or tavern so your customers and patrons can enjoy a perfectly chilled mug of draft beer. Keeping your Glycol cooling system properly maintained on a regular basis reduces your overall maintenance costs.

The kegs are connected to CO2 or nitrogen cylinders through a series of gas blenders and pressure regulators. The ice bath is kept cooler than the desired temperature of the product so as to ensure efficient chilling. Now that we got the main idea of a glycol beer line cooling system, lets take a look at its components and see how it all works. We suggest you to test the waters first and see where it goes. But when should you install a glycol system over a flash chilling system? Get all the equipment that you need to create and assemble the ideal glycol-cooling system for your bar, restaurant, pub, or tavern so your customers and patrons can enjoy a perfectly chilled mug of draft beer. Keeping your Glycol cooling system properly maintained on a regular basis reduces your overall maintenance costs.  Glycol cooling involves wrapping all of your beer lines in an insulated trunk line between your keg cooler and your beer tower. This is a placeholder for the Yext Knolwedge Tags. Most items can be returned up to 30 days from the purchase date. Do not remove this. Beer lines are attached to a shank or faucet thats inside the beer tower. - 200 Feet, 10 Product /4 Glycol Trunk Line 3/8 I.D. - 300 Feet, 2 Product /2 Glycol Trunk Line 3/8 I.D. This will avoid sweating, provide better stability for the structures, and in essence, extend the lifespan of your unit. Structure, drainage, and disposal are some to prepare for properly. Just give us a call to return your item. We provide a variety of equipment and parts for anyone looking to assemble the perfect glycol beer chiller for their bar, tavern, pub, restaurant, or any other facility. Commercial Bar Accessories and Parts (117), Commercial Refrigeration Accessories and Parts (1). Some items, like very large and heavy products, do not qualify at this time. EG-3/4P Glycol chiller - This unit came with in a resable time, Good looking unit , Works very well and easy to install. We recommend glycol-cooled draft beer systems for those looking for longer beer runs for their tavern, pub, or bar. - 125 Feet. Keep your beer and other beverages cold with our awesome selection of Glycol Chillers. Older Post These are the fermentors, glycol lines, and cooler. - 300 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. The size will depend on the quantity of the brew batch you need to cool. The power pack pushes refrigeration (glycol) through the center of the trunk line. All Rights Reserved, Glycol Cooled Beer Taps & Beer Dispensing Towers, Gear Driven Pump for BVL Glycol Beer Chillers, Stainless Steel U Bend Fitting for 3/8" ID Beer Tubing, American Beverage Procon Glycol Recirculating Pump, Shurflo Beer-Ace Gas Pump System for Beer Carbonation, 5 Gallon 100% Glycol Solution for Beer Chiller System, 90' Run Glycol Beer Chiller System | 1/3 HP, 4 Gallon Tank, 25 Run Glycol Beer Chiller System 1/6 HP. Youll find a glycol cooler useful with worts, brite tanks, fermenters, and heat exchangers.

Glycol cooling involves wrapping all of your beer lines in an insulated trunk line between your keg cooler and your beer tower. This is a placeholder for the Yext Knolwedge Tags. Most items can be returned up to 30 days from the purchase date. Do not remove this. Beer lines are attached to a shank or faucet thats inside the beer tower. - 200 Feet, 10 Product /4 Glycol Trunk Line 3/8 I.D. - 300 Feet, 2 Product /2 Glycol Trunk Line 3/8 I.D. This will avoid sweating, provide better stability for the structures, and in essence, extend the lifespan of your unit. Structure, drainage, and disposal are some to prepare for properly. Just give us a call to return your item. We provide a variety of equipment and parts for anyone looking to assemble the perfect glycol beer chiller for their bar, tavern, pub, restaurant, or any other facility. Commercial Bar Accessories and Parts (117), Commercial Refrigeration Accessories and Parts (1). Some items, like very large and heavy products, do not qualify at this time. EG-3/4P Glycol chiller - This unit came with in a resable time, Good looking unit , Works very well and easy to install. We recommend glycol-cooled draft beer systems for those looking for longer beer runs for their tavern, pub, or bar. - 125 Feet. Keep your beer and other beverages cold with our awesome selection of Glycol Chillers. Older Post These are the fermentors, glycol lines, and cooler. - 300 Feet, 14 Product /4 Glycol Trunk Line 5/16 I.D. The size will depend on the quantity of the brew batch you need to cool. The power pack pushes refrigeration (glycol) through the center of the trunk line. All Rights Reserved, Glycol Cooled Beer Taps & Beer Dispensing Towers, Gear Driven Pump for BVL Glycol Beer Chillers, Stainless Steel U Bend Fitting for 3/8" ID Beer Tubing, American Beverage Procon Glycol Recirculating Pump, Shurflo Beer-Ace Gas Pump System for Beer Carbonation, 5 Gallon 100% Glycol Solution for Beer Chiller System, 90' Run Glycol Beer Chiller System | 1/3 HP, 4 Gallon Tank, 25 Run Glycol Beer Chiller System 1/6 HP. Youll find a glycol cooler useful with worts, brite tanks, fermenters, and heat exchangers.  In this article, we talk about its main components, how they work, and how much they cost.

In this article, we talk about its main components, how they work, and how much they cost.  Glycol cooling systems, on the other hand, work well at greater distances and are excellent for beer lines that run up to twenty-five feet or more. We use encrypted SSL security to ensure that your credit card information is always protected. The chilling process works by forcing a cold liquid (glycol) along tubes to a chiller plate, which is usually cast aluminum, and then through the tap system, thereby keeping the beer cold. - 250 Feet, 6 Product /2 Glycol Trunk Line 3/8 I.D.

Glycol cooling systems, on the other hand, work well at greater distances and are excellent for beer lines that run up to twenty-five feet or more. We use encrypted SSL security to ensure that your credit card information is always protected. The chilling process works by forcing a cold liquid (glycol) along tubes to a chiller plate, which is usually cast aluminum, and then through the tap system, thereby keeping the beer cold. - 250 Feet, 6 Product /2 Glycol Trunk Line 3/8 I.D.

Many of our expert Sales Representatives have years of experience in the food-service and beer industries before coming to join us. These are the parts necessary for the movement of heat. This could be very flammable and dangerous to your health once inhaled. For the best experience on our site, be sure to turn on Javascript in your browser. Glycol can lower the freezing point, while water can keep heat capacities high enough out of the fermentors to function efficiently. Would buy again and recommend to everyone. The idea behind a glycol beer line cooler is simple - when the distance between the beer keg cooler (where beer is stored) and the draft beer tower (where beer is dispensed) is longer than 25 feet, chances are you will get foam in your beer - it gets warm too soon, before reaching the tower. It may not be as easy peasy, but it can save you a lot of bucks and time.

Many of our expert Sales Representatives have years of experience in the food-service and beer industries before coming to join us. These are the parts necessary for the movement of heat. This could be very flammable and dangerous to your health once inhaled. For the best experience on our site, be sure to turn on Javascript in your browser. Glycol can lower the freezing point, while water can keep heat capacities high enough out of the fermentors to function efficiently. Would buy again and recommend to everyone. The idea behind a glycol beer line cooler is simple - when the distance between the beer keg cooler (where beer is stored) and the draft beer tower (where beer is dispensed) is longer than 25 feet, chances are you will get foam in your beer - it gets warm too soon, before reaching the tower. It may not be as easy peasy, but it can save you a lot of bucks and time.  Looking for something specific that you didnt find on our website? Trust the experience and industry expertise of Rapids to help you set up your long draw beer cooling system when your serving beer in a different place than your kegs are stored. -150 Feet, 8 Product /2 Glycol Trunk Line 5/16 I.D.

Looking for something specific that you didnt find on our website? Trust the experience and industry expertise of Rapids to help you set up your long draw beer cooling system when your serving beer in a different place than your kegs are stored. -150 Feet, 8 Product /2 Glycol Trunk Line 5/16 I.D.