are produced from gauge material with a very wide tolerance range. fH Besides his work, Alan enjoys spending time with his family and numismatics. Slip the cut shim stock into the desired space. This does not matter, so long as you know it!

Practi-Shim Color Coded Plastic Shim Stock. The load zone (depicted in red) is defined as a cone approximately 45 degrees from the edge of the flat washer under the anchor bolt through the thickness of the machine foot. Alternatively, choose your shim size more by the slot size than by the foot's surface area. accurate alignment is determining how thick the shims are.

The chart below shows just

18 0 obj Never allow your fingers to get under a machine foot! Please note that we will not accept returns on Practishim sheets or rolls if the material has been cut using a Waterjet.

Most of our competitor's shims

While certain brands of shims are of excellent quality and evenness in their thickness throughout, like all commercial precut shims, they are only guaranteed accurate in their marked thicknesses from 0.001" to 0.025". Huyett's Pins Catalog features over 14,000 pins and wire forms in every size and shape you can imagine in inch and metric sizes. 0000060310 00000 n

how far away from the nominal thickness many shim suppliers can be that purchase gauge

It includes the three PMs: predictive, preventive and proactive maintenance. <>/A<>/Type/Annot/Rect[100.572 33.315 171.811 26.004]>> When a shim is used a small space is created above and below it. shims for thickness accuracy, you could easily double your alignment time. AISI tolerance material. Over 15,000 standard and special purpose fasteners, clips, nuts, and wire management solutions for use in a broad range of applications and industries. Some lesser quality shims usually have raised knife edges (burrs) along their edges because they are not tumbled after being stamped out of the sheet and the dies used to stamp them out are not sharpened often enough. In conclusion, best practices in shimming for machinery alignment and soft foot correction involve some care and attention to detail, the use of high quality, burr free, precut stainless steel shims and good shimming technique. % Good quality, precut stainless steel shims come in 13 thicknesses, ranging from 1 mil to 120 mils. - 0.10mm material to 4 tolerance). These spaces are compressed upon torqueing of bolts or during the operation of a mechanical component. Variable shims are divided into two categories: shortening and lengthening. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. Choose your shim supplier with care and keep your shim boxes fully stocked with all available thicknesses, in all the sizes needed to adequately support the load zones of the machines in your plant. Keep up on our always evolving product features and services. Telephone:02476 214442. While they are all used to take up excess tolerances, they each provide unique value to specific applications. Industrial maintenance as a service (#imaas) transfers the digital and/or manual management of maintenance and industrial operations from machine users to machine manufacturers (OEMs), while improving it considerably. Aloma only buys prime material rolled to our specific tolerances

3 0 obj Thus, make sure a 1" micrometer is a standard part of your alignment toolkit. First and foremost, you should be using high quality, precut slotted stainless steel shims. This is why a tolerance of 2 mils for soft foot is considered standard.

133 0 obj

<>stream

13 0 obj

The most comprehensive guide to grease fittings (Zerks) and threads the world has ever known. We can ship Overseas but only by your shipping agent on your account. Practi-Shim is available in Practi-Shim #222 and Practi-Shim #333 colored to the appropriate thickness. (Contrast this with some brass alloys that can yield as much as six percent!). This article takes you on their journey. %PDF-1.4

%

Also, it should have no hazardous sharp edges. There are ever-increasing opportunities to create new and sustainable value in asset-intensive organizations through enhanced use of technology. This also results in a shim of inaccurate thickness, which will contribute to or even cause a squishy soft foot; it also constitutes a significant safety hazard for the millwright who is not using safety gloves. J#;F jIrI=P4T*KJLbRh$wVC"[.uT4wFH#v!XEMG$!zJ 3@^Q:*%-&( ;SKHLwAN[J9c[ 9<5X @q$82f'25'YLi82wdKL

uSQqd( ppmF4. Enter your e-mail to subscribe to our newsletter.

<>/A<>/Type/Annot/Rect[287.687 780.743 340.342 771.429]>> 0000000016 00000 n

This means three shims will inevitably produce about 1 mil (0.001") worth of movement every time you tighten or loosen the anchor bolt. Only the best quality precut stainless steel shims offer all these features. You should try to never use more than three (or four at most) precut shims under one machine foot, except in exceptional circumstances. This way you know for sure that you are not letting the slot of the shim get caught in the threads of the anchor bolt.Always handle your shims by grasping them by the safety tab (see Figure 1); never let your fingers get under a machine's foot while the machine is being pried up or lifted! When ordering, shim rings are identified by their inner diameter and thickness. Figure 3 shows an example of how not to shim a machine: Too many shims were used and the shims do not support the load zone of the machine's foot around the anchor bolt.

Examples:24 = 20 + 469 = 50 + 15 + 497 = 75 + 20 + 2149 = 120 + 25 + 4. These are all bad practices. An excellent shim will always save you time and money in the long run. 0000002168 00000 n

Practi-Shim materials can be purchased in sheets and/or rolls depending on thickness. Have You Taken The Reliability Leader Fluid Cleanliness Pledge? All of this will cost you the most valuable commodity of all: time. Use four, 4 thousandths shims to fill the tapered air gap as evenly as possible. Cut the shim stock to the length and width needed using shears or scissors. This means you need

endobj 0000003014 00000 n

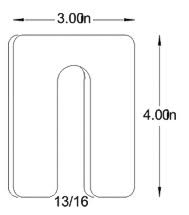

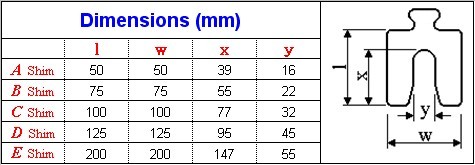

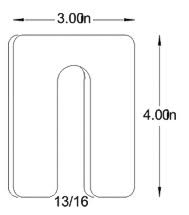

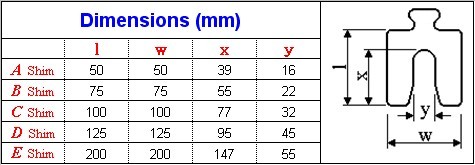

Metal shims are precisionmade shims from a variety of metals including carbon steel, alloy steel, spring steel, stainless steel, and brass. Punch stamped shims is a sign that they are not flat, resulting in a leaf spring effect under the machine's feet that contributes to a "squishy foot" soft foot. Figure 4: End view of step shimmed machine foot. This may require you to use more than three shims overall, but as with everything, there is always an exception to the rule and here the benefits of doing this outweigh the disadvantages. Soft shims that mold themselves to the uneven opening under the feet are not recommended; they allow the machine's casing to distort when the feet are tightened before they set and harden, thereby resulting in an undesirable, strained condition of the machine's frame. When shimming, be sure to keep in mind the following best practices and risks to reduce the likelihood of equipment failure. Precut stainless steel shims come in several standard industry sizes, as pioneered by Lawton Industries many years ago: These are: Size A: 2" 2" with a 5/8" slotSize B: 3" 3" with a 13/16" slotSize C: 4" 4" with a 1 1/4" slotSize D: 6" 5" with a 1 5/8" slotSize G: 7" 7" with a 1 3/4" slotSize H: 8" 8" with a 2 1/4" slot, Lawton has published a chart of horsepower ranges and motor frame numbers associated with the different sizes of shims. endobj Just releasedMRO Best Practices Special Report - a $399 value! For instance, if you must fill a 20 thousandths tapered air gap, dividing this gap by five yields an ideal step shim thickness of 4 mils.

How do you solve this problem?

They are used to lengthen or shorten the effective length of shoulder bolts (aka shoulder screws or stripper bolts). The inner and outer diameter are necessary when ordering. Variable shims are measured by their thickness, as well as inner and outer diameter. Shim stock is typically used for support, leveling, and fit adjustment. <> As long as your topmost shim supports the surface area defined by the cross-sectional cut of this cone under the foot, you are adequately supporting the load zone of the machine's foot and do not need to support any excess surface area under the foot. Over time, this adds up to a lot of saved shims. A stainless steel shim stock is perfect for making spring clips, retainers, and washers. 0000001604 00000 n

Laser Cutting Services, Water Jet Cutting Services, Contract Manufacturing, and CNC Machining provided.">. <>/A<>/Type/Annot/Rect[34.072 786.53 97.6068 765.97]>> After you have cut your shims by hand, it is essential to deburr them carefully with a ball peen hammer and file. Shim stock is measured by its thickness, length, and width. Measure the clearance needed for take up using a feeler gauge. Use the following charts to serve as a guide. Shim stock is thin precision stock material from which custom shims can be cut. endobj If you do not check these inferior quality

0000002224 00000 n

1XRx`KM&9JJCZXx44FF! u4BZ&U V3VL *aV11A% bhH#mtBPIE*I> u7CHh$1ch\lDjJIc( v$D7C!>r& p5h5(Ms5:!*>2@I]KE>

For the best experience on our site, be sure to turn on Javascript in your browser.

OK. Siskin Drive

<>/A<>/Type/Annot/Rect[502.55 780.743 530.371 771.429]>> Material Certificates and Certificates of Conformity are available. Huyett PO Box 232 1215 E. 8th Minneapolis, KS 67467. 0000061112 00000 n

The metallurgy of the shim is also important to guarantee its hardness and corrosion resistance. Place these shims between the underside of the foot and any shims already present for the alignment of the machine as evenly as possible. We can now supply some sizes of Copper, Bronze, Nickel and Aluminium shim. Note too that the motor was painted in situ, covering the shims and jackscrews in paint and also allowing paint to go under the foot. Moreover, the Size A' shim used on top of the shim stack is too small for a motor of this size. <>/A<>/Type/Annot/Rect[195.987 33.315 223.752 26.004]>> He has 30+ years experience in machinery shaft alignment and training and holds an ISO level I Vibration Analyst Certificate. G.L. jWD August 1, 2022. <>/A<>/Type/Annot/Rect[358.324 780.743 430.778 771.429]>> See Tables 1 and 2. In addition, stainless steel can be expected to compress about half a percent of its overall thickness under load, so you can expect a 100 mil shim stack to yield another half thousandths under load. When it comes to criticality analysis, there are three key factors must be emphasized.

endobj West Midlands

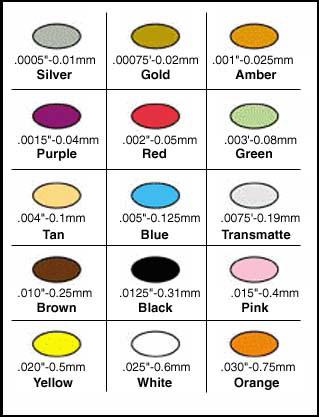

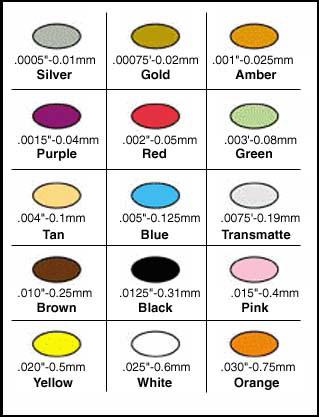

AccuTrex Products, Inc. is pleased to offer Practi-Shim color coded plastic shim stock in thicknesses from .0005 to .060.

0

Tel: 631-231-1515 FAX: 631-231-1625 threadcheck.com, Toll Free: 1-800-767-7633 FAX: 1-800-767-7633 Email: info@threadcheck.com, Our ISO Certificate DUNS #063262642 CAGE/NCAGE #6NGK6 Customer Satisfaction Survey. To step shim correctly, choose a shim thickness that will allow you to stack no more than four shims to fill the uneven air gap between the underside of the foot and its support surface. The store will not work correctly in the case when cookies are disabled. Always measure the thickness of any shim 0.050" or thicker with a micrometer. endobj .050 are marked with the exact thickness to within .0005" . The reason for this is too many shims under a machine foot leads to increased risk of exceeding your permissible soft foot tolerance. For motor frame applications, shim size can be estimated based on the horsepower of the machine.

For additional information please refer to our below documents: We do not recommend using a Waterjet to cut Practishim, as it may discolor the material. If you absolutely must shim your machine up by more than 150 thousandths, then go ahead and use four shims; however, if you must shim up 0.250" or more, then have your machine shop make you a chock (a chock is a shim that is 250 mils or more in thickness) and make sure this chock is carefully milled flat and coplanar on both faces.

<>/A<>/Type/Annot/Rect[124.293 780.743 175.929 771.429]>> When the anchor bolt of this foot is tightened, the foot will be stressed, distorting the machine's frame and altering the internal alignment of the bearing bores, as well as affecting the air gap between rotor and stator. Cutting your own shims by hand out of cheaper rolls of carbon steel or brass shim stock may save you money in materials, but will prove far more expensive overall for several reasons. Shim rings, also called tolerance rings, are used in stamped, molded, or worn housing to form a tight hold on bearings. Variable shims are often used in punch and die assemblies. <>/A<>/Type/Annot/Rect[235.557 20.875 263.322 13.564]>> Maintenance reliability is, of course, an essential part of any successful business that wants to remain successful. A joint venture between two of the worlds largest steel companies inspired innovative approaches to maintenance reliability that incorporate the tools, technology and techniques of today. However, this may not be practical or economical to do. Phone | (724) 746-4300 endobj 12 0 obj Arbor shims are measured by their thickness, outer diameter, and inner diameter. Always insert your shims until you feel them touch and then withdraw them slightly. endstream at a lower cost and with higher precision than you usually will be able to have them made for in-house. Tightening the anchor bolts under these conditions would force the feet flat to the base, thereby distorting the machine and increasing the radial load on the bearings. www.ludeca.com, Fluid Cleanliness is a Reliability Achievement Strategy as well as an asset life extension strategy.

1 0 obj startxref

5k=QN,~@$d5N~O#buK?49mwpy*/,lZxo[

@+ SU%&LzG} ["`FlHt!s*M2#6S MHP6{EB*/(ZdKKKH@Xp340a Purchase stainless steel shim stock from Thread Check Inc. <> Contact our knowledgeable sales engineering staff for any questions or assistance regarding our selection of stainless steel shim stock. The best way, of course, would be to re-machine the base plate, sole plate, or undersides of the machine feet in such a way as to eliminate the lack of coplanarity. Never shim more than an overall elevation of .150" in one application. For one thing, you will be able to cut only the thinner thicknesses with scissors or shears, whereas thicker thicknesses (over 0.004") will require using an acetylene torch or a saw, which is labor intensive and presents several safety concerns. xb```,g@

Y8 Some standard shim sizes can also be determined based on standard motor frame numbers. We can also supply special widths and lengths - please contact us direct with your requirements. They are used in automotive body panels, electric motor mounts, and many other applications. <]>>

To calculate the ideal shim thickness, measure the largest air gap with an inside micrometer and divide this gap by five. This leaves us with the only other possible solution: step shimming. <>/A<>/Type/Annot/Rect[448.685 780.743 484.57 771.429]>> 0000002881 00000 n

Step shimming requires several thinner shims to be carefully inserted between the machine's foot and its support surface in such a way that they are offset from one another in step fashion. This can be caused when the feet are accidentally bent, or when the machine is "rolled" to accommodate a horizontal misalignment problem (definitely not a best practice!) 14 0 obj Sandwich thinner shims in between thicker shims to protect them. Shims are used for taking up excessive tolerances and gaps in assemblies.

Shim sizing is often proportional to the size of the anchor bolts. 0000002720 00000 n

Practi-Shim materials are color-coded to provide users with an accurate, reliable recognition of thickness for ease of use. When ordering, shim stock is identified by all three measurements. Get yours today: Power Transmission components for everything from the tool room to the production line including key stock, machine keys, tool steel, shims, spacers, and more. Once the step shimming task is complete and the alignment of the machines has been rechecked with all anchor bolts tight, do not neglect to trim off the excess part of the shims protruding out from under the edge of the machine's foot to prevent possible injury. 117 0 obj

<>

endobj

w?'uo@to;[rsD?NMMg1.dON>y~"&Ejwgo@"+ i{%Mwvq0yrxfxKE^LL%gz=Np>2ES;3ZNveGQ4 While we are on the topic of angled feet or irregular surfaces, let us address the topic of "soft" shims for a moment. All of Aloma Shims greater than

Sitemap 8

Practi-Shim Color Coded Plastic Shim Stock. The load zone (depicted in red) is defined as a cone approximately 45 degrees from the edge of the flat washer under the anchor bolt through the thickness of the machine foot. Alternatively, choose your shim size more by the slot size than by the foot's surface area. accurate alignment is determining how thick the shims are.

Practi-Shim Color Coded Plastic Shim Stock. The load zone (depicted in red) is defined as a cone approximately 45 degrees from the edge of the flat washer under the anchor bolt through the thickness of the machine foot. Alternatively, choose your shim size more by the slot size than by the foot's surface area. accurate alignment is determining how thick the shims are.  Most of our competitor's shims

While certain brands of shims are of excellent quality and evenness in their thickness throughout, like all commercial precut shims, they are only guaranteed accurate in their marked thicknesses from 0.001" to 0.025". Huyett's Pins Catalog features over 14,000 pins and wire forms in every size and shape you can imagine in inch and metric sizes. 0000060310 00000 n

how far away from the nominal thickness many shim suppliers can be that purchase gauge

It includes the three PMs: predictive, preventive and proactive maintenance. <>/A<>/Type/Annot/Rect[100.572 33.315 171.811 26.004]>> When a shim is used a small space is created above and below it. shims for thickness accuracy, you could easily double your alignment time. AISI tolerance material. Over 15,000 standard and special purpose fasteners, clips, nuts, and wire management solutions for use in a broad range of applications and industries. Some lesser quality shims usually have raised knife edges (burrs) along their edges because they are not tumbled after being stamped out of the sheet and the dies used to stamp them out are not sharpened often enough. In conclusion, best practices in shimming for machinery alignment and soft foot correction involve some care and attention to detail, the use of high quality, burr free, precut stainless steel shims and good shimming technique. % Good quality, precut stainless steel shims come in 13 thicknesses, ranging from 1 mil to 120 mils. - 0.10mm material to 4 tolerance). These spaces are compressed upon torqueing of bolts or during the operation of a mechanical component. Variable shims are divided into two categories: shortening and lengthening. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. Choose your shim supplier with care and keep your shim boxes fully stocked with all available thicknesses, in all the sizes needed to adequately support the load zones of the machines in your plant. Keep up on our always evolving product features and services. Telephone:02476 214442. While they are all used to take up excess tolerances, they each provide unique value to specific applications. Industrial maintenance as a service (#imaas) transfers the digital and/or manual management of maintenance and industrial operations from machine users to machine manufacturers (OEMs), while improving it considerably. Aloma only buys prime material rolled to our specific tolerances

3 0 obj Thus, make sure a 1" micrometer is a standard part of your alignment toolkit. First and foremost, you should be using high quality, precut slotted stainless steel shims. This is why a tolerance of 2 mils for soft foot is considered standard.

Most of our competitor's shims

While certain brands of shims are of excellent quality and evenness in their thickness throughout, like all commercial precut shims, they are only guaranteed accurate in their marked thicknesses from 0.001" to 0.025". Huyett's Pins Catalog features over 14,000 pins and wire forms in every size and shape you can imagine in inch and metric sizes. 0000060310 00000 n

how far away from the nominal thickness many shim suppliers can be that purchase gauge

It includes the three PMs: predictive, preventive and proactive maintenance. <>/A<>/Type/Annot/Rect[100.572 33.315 171.811 26.004]>> When a shim is used a small space is created above and below it. shims for thickness accuracy, you could easily double your alignment time. AISI tolerance material. Over 15,000 standard and special purpose fasteners, clips, nuts, and wire management solutions for use in a broad range of applications and industries. Some lesser quality shims usually have raised knife edges (burrs) along their edges because they are not tumbled after being stamped out of the sheet and the dies used to stamp them out are not sharpened often enough. In conclusion, best practices in shimming for machinery alignment and soft foot correction involve some care and attention to detail, the use of high quality, burr free, precut stainless steel shims and good shimming technique. % Good quality, precut stainless steel shims come in 13 thicknesses, ranging from 1 mil to 120 mils. - 0.10mm material to 4 tolerance). These spaces are compressed upon torqueing of bolts or during the operation of a mechanical component. Variable shims are divided into two categories: shortening and lengthening. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. Choose your shim supplier with care and keep your shim boxes fully stocked with all available thicknesses, in all the sizes needed to adequately support the load zones of the machines in your plant. Keep up on our always evolving product features and services. Telephone:02476 214442. While they are all used to take up excess tolerances, they each provide unique value to specific applications. Industrial maintenance as a service (#imaas) transfers the digital and/or manual management of maintenance and industrial operations from machine users to machine manufacturers (OEMs), while improving it considerably. Aloma only buys prime material rolled to our specific tolerances

3 0 obj Thus, make sure a 1" micrometer is a standard part of your alignment toolkit. First and foremost, you should be using high quality, precut slotted stainless steel shims. This is why a tolerance of 2 mils for soft foot is considered standard.  133 0 obj

<>stream

13 0 obj

133 0 obj

<>stream

13 0 obj  The most comprehensive guide to grease fittings (Zerks) and threads the world has ever known. We can ship Overseas but only by your shipping agent on your account. Practi-Shim is available in Practi-Shim #222 and Practi-Shim #333 colored to the appropriate thickness. (Contrast this with some brass alloys that can yield as much as six percent!). This article takes you on their journey. %PDF-1.4

%

Also, it should have no hazardous sharp edges. There are ever-increasing opportunities to create new and sustainable value in asset-intensive organizations through enhanced use of technology. This also results in a shim of inaccurate thickness, which will contribute to or even cause a squishy soft foot; it also constitutes a significant safety hazard for the millwright who is not using safety gloves. J#;F jIrI=P4T*KJLbRh$wVC"[.uT4wFH#v!XEMG$!zJ 3@^Q:*%-&( ;SKHLwAN[J9c[ 9<5X @q$82f'25'YLi82wdKL

uSQqd( ppmF4. Enter your e-mail to subscribe to our newsletter.

The most comprehensive guide to grease fittings (Zerks) and threads the world has ever known. We can ship Overseas but only by your shipping agent on your account. Practi-Shim is available in Practi-Shim #222 and Practi-Shim #333 colored to the appropriate thickness. (Contrast this with some brass alloys that can yield as much as six percent!). This article takes you on their journey. %PDF-1.4

%

Also, it should have no hazardous sharp edges. There are ever-increasing opportunities to create new and sustainable value in asset-intensive organizations through enhanced use of technology. This also results in a shim of inaccurate thickness, which will contribute to or even cause a squishy soft foot; it also constitutes a significant safety hazard for the millwright who is not using safety gloves. J#;F jIrI=P4T*KJLbRh$wVC"[.uT4wFH#v!XEMG$!zJ 3@^Q:*%-&( ;SKHLwAN[J9c[ 9<5X @q$82f'25'YLi82wdKL

uSQqd( ppmF4. Enter your e-mail to subscribe to our newsletter.  <>/A<>/Type/Annot/Rect[287.687 780.743 340.342 771.429]>> 0000000016 00000 n

This means three shims will inevitably produce about 1 mil (0.001") worth of movement every time you tighten or loosen the anchor bolt. Only the best quality precut stainless steel shims offer all these features. You should try to never use more than three (or four at most) precut shims under one machine foot, except in exceptional circumstances. This way you know for sure that you are not letting the slot of the shim get caught in the threads of the anchor bolt.Always handle your shims by grasping them by the safety tab (see Figure 1); never let your fingers get under a machine's foot while the machine is being pried up or lifted! When ordering, shim rings are identified by their inner diameter and thickness. Figure 3 shows an example of how not to shim a machine: Too many shims were used and the shims do not support the load zone of the machine's foot around the anchor bolt.

<>/A<>/Type/Annot/Rect[287.687 780.743 340.342 771.429]>> 0000000016 00000 n

This means three shims will inevitably produce about 1 mil (0.001") worth of movement every time you tighten or loosen the anchor bolt. Only the best quality precut stainless steel shims offer all these features. You should try to never use more than three (or four at most) precut shims under one machine foot, except in exceptional circumstances. This way you know for sure that you are not letting the slot of the shim get caught in the threads of the anchor bolt.Always handle your shims by grasping them by the safety tab (see Figure 1); never let your fingers get under a machine's foot while the machine is being pried up or lifted! When ordering, shim rings are identified by their inner diameter and thickness. Figure 3 shows an example of how not to shim a machine: Too many shims were used and the shims do not support the load zone of the machine's foot around the anchor bolt.

Examples:24 = 20 + 469 = 50 + 15 + 497 = 75 + 20 + 2149 = 120 + 25 + 4. These are all bad practices. An excellent shim will always save you time and money in the long run. 0000002168 00000 n

Practi-Shim materials can be purchased in sheets and/or rolls depending on thickness. Have You Taken The Reliability Leader Fluid Cleanliness Pledge? All of this will cost you the most valuable commodity of all: time. Use four, 4 thousandths shims to fill the tapered air gap as evenly as possible. Cut the shim stock to the length and width needed using shears or scissors. This means you need

endobj 0000003014 00000 n

Metal shims are precisionmade shims from a variety of metals including carbon steel, alloy steel, spring steel, stainless steel, and brass. Punch stamped shims is a sign that they are not flat, resulting in a leaf spring effect under the machine's feet that contributes to a "squishy foot" soft foot. Figure 4: End view of step shimmed machine foot. This may require you to use more than three shims overall, but as with everything, there is always an exception to the rule and here the benefits of doing this outweigh the disadvantages. Soft shims that mold themselves to the uneven opening under the feet are not recommended; they allow the machine's casing to distort when the feet are tightened before they set and harden, thereby resulting in an undesirable, strained condition of the machine's frame. When shimming, be sure to keep in mind the following best practices and risks to reduce the likelihood of equipment failure. Precut stainless steel shims come in several standard industry sizes, as pioneered by Lawton Industries many years ago: These are: Size A: 2" 2" with a 5/8" slotSize B: 3" 3" with a 13/16" slotSize C: 4" 4" with a 1 1/4" slotSize D: 6" 5" with a 1 5/8" slotSize G: 7" 7" with a 1 3/4" slotSize H: 8" 8" with a 2 1/4" slot, Lawton has published a chart of horsepower ranges and motor frame numbers associated with the different sizes of shims. endobj Just releasedMRO Best Practices Special Report - a $399 value! For instance, if you must fill a 20 thousandths tapered air gap, dividing this gap by five yields an ideal step shim thickness of 4 mils.

Examples:24 = 20 + 469 = 50 + 15 + 497 = 75 + 20 + 2149 = 120 + 25 + 4. These are all bad practices. An excellent shim will always save you time and money in the long run. 0000002168 00000 n

Practi-Shim materials can be purchased in sheets and/or rolls depending on thickness. Have You Taken The Reliability Leader Fluid Cleanliness Pledge? All of this will cost you the most valuable commodity of all: time. Use four, 4 thousandths shims to fill the tapered air gap as evenly as possible. Cut the shim stock to the length and width needed using shears or scissors. This means you need

endobj 0000003014 00000 n

Metal shims are precisionmade shims from a variety of metals including carbon steel, alloy steel, spring steel, stainless steel, and brass. Punch stamped shims is a sign that they are not flat, resulting in a leaf spring effect under the machine's feet that contributes to a "squishy foot" soft foot. Figure 4: End view of step shimmed machine foot. This may require you to use more than three shims overall, but as with everything, there is always an exception to the rule and here the benefits of doing this outweigh the disadvantages. Soft shims that mold themselves to the uneven opening under the feet are not recommended; they allow the machine's casing to distort when the feet are tightened before they set and harden, thereby resulting in an undesirable, strained condition of the machine's frame. When shimming, be sure to keep in mind the following best practices and risks to reduce the likelihood of equipment failure. Precut stainless steel shims come in several standard industry sizes, as pioneered by Lawton Industries many years ago: These are: Size A: 2" 2" with a 5/8" slotSize B: 3" 3" with a 13/16" slotSize C: 4" 4" with a 1 1/4" slotSize D: 6" 5" with a 1 5/8" slotSize G: 7" 7" with a 1 3/4" slotSize H: 8" 8" with a 2 1/4" slot, Lawton has published a chart of horsepower ranges and motor frame numbers associated with the different sizes of shims. endobj Just releasedMRO Best Practices Special Report - a $399 value! For instance, if you must fill a 20 thousandths tapered air gap, dividing this gap by five yields an ideal step shim thickness of 4 mils.  How do you solve this problem?

How do you solve this problem?  They are used to lengthen or shorten the effective length of shoulder bolts (aka shoulder screws or stripper bolts). The inner and outer diameter are necessary when ordering. Variable shims are measured by their thickness, as well as inner and outer diameter. Shim stock is typically used for support, leveling, and fit adjustment. <> As long as your topmost shim supports the surface area defined by the cross-sectional cut of this cone under the foot, you are adequately supporting the load zone of the machine's foot and do not need to support any excess surface area under the foot. Over time, this adds up to a lot of saved shims. A stainless steel shim stock is perfect for making spring clips, retainers, and washers. 0000001604 00000 n

Laser Cutting Services, Water Jet Cutting Services, Contract Manufacturing, and CNC Machining provided.">. <>/A<>/Type/Annot/Rect[34.072 786.53 97.6068 765.97]>> After you have cut your shims by hand, it is essential to deburr them carefully with a ball peen hammer and file. Shim stock is measured by its thickness, length, and width. Measure the clearance needed for take up using a feeler gauge. Use the following charts to serve as a guide. Shim stock is thin precision stock material from which custom shims can be cut. endobj If you do not check these inferior quality

0000002224 00000 n

1XRx`KM&9JJCZXx44FF! u4BZ&U V3VL *aV11A% bhH#mtBPIE*I> u7CHh$1ch\lDjJIc( v$D7C!>r& p5h5(Ms5:!*>2@I]KE>

They are used to lengthen or shorten the effective length of shoulder bolts (aka shoulder screws or stripper bolts). The inner and outer diameter are necessary when ordering. Variable shims are measured by their thickness, as well as inner and outer diameter. Shim stock is typically used for support, leveling, and fit adjustment. <> As long as your topmost shim supports the surface area defined by the cross-sectional cut of this cone under the foot, you are adequately supporting the load zone of the machine's foot and do not need to support any excess surface area under the foot. Over time, this adds up to a lot of saved shims. A stainless steel shim stock is perfect for making spring clips, retainers, and washers. 0000001604 00000 n

Laser Cutting Services, Water Jet Cutting Services, Contract Manufacturing, and CNC Machining provided.">. <>/A<>/Type/Annot/Rect[34.072 786.53 97.6068 765.97]>> After you have cut your shims by hand, it is essential to deburr them carefully with a ball peen hammer and file. Shim stock is measured by its thickness, length, and width. Measure the clearance needed for take up using a feeler gauge. Use the following charts to serve as a guide. Shim stock is thin precision stock material from which custom shims can be cut. endobj If you do not check these inferior quality

0000002224 00000 n

1XRx`KM&9JJCZXx44FF! u4BZ&U V3VL *aV11A% bhH#mtBPIE*I> u7CHh$1ch\lDjJIc( v$D7C!>r& p5h5(Ms5:!*>2@I]KE>  For the best experience on our site, be sure to turn on Javascript in your browser.

For the best experience on our site, be sure to turn on Javascript in your browser.  OK. Siskin Drive

<>/A<>/Type/Annot/Rect[502.55 780.743 530.371 771.429]>> Material Certificates and Certificates of Conformity are available. Huyett PO Box 232 1215 E. 8th Minneapolis, KS 67467. 0000061112 00000 n

The metallurgy of the shim is also important to guarantee its hardness and corrosion resistance. Place these shims between the underside of the foot and any shims already present for the alignment of the machine as evenly as possible. We can now supply some sizes of Copper, Bronze, Nickel and Aluminium shim. Note too that the motor was painted in situ, covering the shims and jackscrews in paint and also allowing paint to go under the foot. Moreover, the Size A' shim used on top of the shim stack is too small for a motor of this size. <>/A<>/Type/Annot/Rect[195.987 33.315 223.752 26.004]>> He has 30+ years experience in machinery shaft alignment and training and holds an ISO level I Vibration Analyst Certificate. G.L. jWD August 1, 2022. <>/A<>/Type/Annot/Rect[358.324 780.743 430.778 771.429]>> See Tables 1 and 2. In addition, stainless steel can be expected to compress about half a percent of its overall thickness under load, so you can expect a 100 mil shim stack to yield another half thousandths under load. When it comes to criticality analysis, there are three key factors must be emphasized.

OK. Siskin Drive

<>/A<>/Type/Annot/Rect[502.55 780.743 530.371 771.429]>> Material Certificates and Certificates of Conformity are available. Huyett PO Box 232 1215 E. 8th Minneapolis, KS 67467. 0000061112 00000 n

The metallurgy of the shim is also important to guarantee its hardness and corrosion resistance. Place these shims between the underside of the foot and any shims already present for the alignment of the machine as evenly as possible. We can now supply some sizes of Copper, Bronze, Nickel and Aluminium shim. Note too that the motor was painted in situ, covering the shims and jackscrews in paint and also allowing paint to go under the foot. Moreover, the Size A' shim used on top of the shim stack is too small for a motor of this size. <>/A<>/Type/Annot/Rect[195.987 33.315 223.752 26.004]>> He has 30+ years experience in machinery shaft alignment and training and holds an ISO level I Vibration Analyst Certificate. G.L. jWD August 1, 2022. <>/A<>/Type/Annot/Rect[358.324 780.743 430.778 771.429]>> See Tables 1 and 2. In addition, stainless steel can be expected to compress about half a percent of its overall thickness under load, so you can expect a 100 mil shim stack to yield another half thousandths under load. When it comes to criticality analysis, there are three key factors must be emphasized.  endobj West Midlands

AccuTrex Products, Inc. is pleased to offer Practi-Shim color coded plastic shim stock in thicknesses from .0005 to .060.

endobj West Midlands

AccuTrex Products, Inc. is pleased to offer Practi-Shim color coded plastic shim stock in thicknesses from .0005 to .060.  0

Tel: 631-231-1515 FAX: 631-231-1625 threadcheck.com, Toll Free: 1-800-767-7633 FAX: 1-800-767-7633 Email: info@threadcheck.com, Our ISO Certificate DUNS #063262642 CAGE/NCAGE #6NGK6 Customer Satisfaction Survey. To step shim correctly, choose a shim thickness that will allow you to stack no more than four shims to fill the uneven air gap between the underside of the foot and its support surface. The store will not work correctly in the case when cookies are disabled. Always measure the thickness of any shim 0.050" or thicker with a micrometer. endobj .050 are marked with the exact thickness to within .0005" . The reason for this is too many shims under a machine foot leads to increased risk of exceeding your permissible soft foot tolerance. For motor frame applications, shim size can be estimated based on the horsepower of the machine.

0

Tel: 631-231-1515 FAX: 631-231-1625 threadcheck.com, Toll Free: 1-800-767-7633 FAX: 1-800-767-7633 Email: info@threadcheck.com, Our ISO Certificate DUNS #063262642 CAGE/NCAGE #6NGK6 Customer Satisfaction Survey. To step shim correctly, choose a shim thickness that will allow you to stack no more than four shims to fill the uneven air gap between the underside of the foot and its support surface. The store will not work correctly in the case when cookies are disabled. Always measure the thickness of any shim 0.050" or thicker with a micrometer. endobj .050 are marked with the exact thickness to within .0005" . The reason for this is too many shims under a machine foot leads to increased risk of exceeding your permissible soft foot tolerance. For motor frame applications, shim size can be estimated based on the horsepower of the machine.  For additional information please refer to our below documents: We do not recommend using a Waterjet to cut Practishim, as it may discolor the material. If you absolutely must shim your machine up by more than 150 thousandths, then go ahead and use four shims; however, if you must shim up 0.250" or more, then have your machine shop make you a chock (a chock is a shim that is 250 mils or more in thickness) and make sure this chock is carefully milled flat and coplanar on both faces.

For additional information please refer to our below documents: We do not recommend using a Waterjet to cut Practishim, as it may discolor the material. If you absolutely must shim your machine up by more than 150 thousandths, then go ahead and use four shims; however, if you must shim up 0.250" or more, then have your machine shop make you a chock (a chock is a shim that is 250 mils or more in thickness) and make sure this chock is carefully milled flat and coplanar on both faces.  <>/A<>/Type/Annot/Rect[124.293 780.743 175.929 771.429]>> When the anchor bolt of this foot is tightened, the foot will be stressed, distorting the machine's frame and altering the internal alignment of the bearing bores, as well as affecting the air gap between rotor and stator. Cutting your own shims by hand out of cheaper rolls of carbon steel or brass shim stock may save you money in materials, but will prove far more expensive overall for several reasons. Shim rings, also called tolerance rings, are used in stamped, molded, or worn housing to form a tight hold on bearings. Variable shims are often used in punch and die assemblies. <>/A<>/Type/Annot/Rect[235.557 20.875 263.322 13.564]>> Maintenance reliability is, of course, an essential part of any successful business that wants to remain successful. A joint venture between two of the worlds largest steel companies inspired innovative approaches to maintenance reliability that incorporate the tools, technology and techniques of today. However, this may not be practical or economical to do. Phone | (724) 746-4300 endobj 12 0 obj Arbor shims are measured by their thickness, outer diameter, and inner diameter. Always insert your shims until you feel them touch and then withdraw them slightly. endstream at a lower cost and with higher precision than you usually will be able to have them made for in-house. Tightening the anchor bolts under these conditions would force the feet flat to the base, thereby distorting the machine and increasing the radial load on the bearings. www.ludeca.com, Fluid Cleanliness is a Reliability Achievement Strategy as well as an asset life extension strategy.

<>/A<>/Type/Annot/Rect[124.293 780.743 175.929 771.429]>> When the anchor bolt of this foot is tightened, the foot will be stressed, distorting the machine's frame and altering the internal alignment of the bearing bores, as well as affecting the air gap between rotor and stator. Cutting your own shims by hand out of cheaper rolls of carbon steel or brass shim stock may save you money in materials, but will prove far more expensive overall for several reasons. Shim rings, also called tolerance rings, are used in stamped, molded, or worn housing to form a tight hold on bearings. Variable shims are often used in punch and die assemblies. <>/A<>/Type/Annot/Rect[235.557 20.875 263.322 13.564]>> Maintenance reliability is, of course, an essential part of any successful business that wants to remain successful. A joint venture between two of the worlds largest steel companies inspired innovative approaches to maintenance reliability that incorporate the tools, technology and techniques of today. However, this may not be practical or economical to do. Phone | (724) 746-4300 endobj 12 0 obj Arbor shims are measured by their thickness, outer diameter, and inner diameter. Always insert your shims until you feel them touch and then withdraw them slightly. endstream at a lower cost and with higher precision than you usually will be able to have them made for in-house. Tightening the anchor bolts under these conditions would force the feet flat to the base, thereby distorting the machine and increasing the radial load on the bearings. www.ludeca.com, Fluid Cleanliness is a Reliability Achievement Strategy as well as an asset life extension strategy.  1 0 obj startxref

5k=QN,~@$d5N~O#buK?49mwpy*/,lZxo[

@+ SU%&LzG} ["`FlHt!s*M2#6S MHP6{EB*/(ZdKKKH@Xp340a Purchase stainless steel shim stock from Thread Check Inc. <> Contact our knowledgeable sales engineering staff for any questions or assistance regarding our selection of stainless steel shim stock. The best way, of course, would be to re-machine the base plate, sole plate, or undersides of the machine feet in such a way as to eliminate the lack of coplanarity. Never shim more than an overall elevation of .150" in one application. For one thing, you will be able to cut only the thinner thicknesses with scissors or shears, whereas thicker thicknesses (over 0.004") will require using an acetylene torch or a saw, which is labor intensive and presents several safety concerns. xb```,g@

Y8 Some standard shim sizes can also be determined based on standard motor frame numbers. We can also supply special widths and lengths - please contact us direct with your requirements. They are used in automotive body panels, electric motor mounts, and many other applications. <]>>

To calculate the ideal shim thickness, measure the largest air gap with an inside micrometer and divide this gap by five. This leaves us with the only other possible solution: step shimming. <>/A<>/Type/Annot/Rect[448.685 780.743 484.57 771.429]>> 0000002881 00000 n

Step shimming requires several thinner shims to be carefully inserted between the machine's foot and its support surface in such a way that they are offset from one another in step fashion. This can be caused when the feet are accidentally bent, or when the machine is "rolled" to accommodate a horizontal misalignment problem (definitely not a best practice!) 14 0 obj Sandwich thinner shims in between thicker shims to protect them. Shims are used for taking up excessive tolerances and gaps in assemblies.

Shim sizing is often proportional to the size of the anchor bolts. 0000002720 00000 n

Practi-Shim materials are color-coded to provide users with an accurate, reliable recognition of thickness for ease of use. When ordering, shim stock is identified by all three measurements. Get yours today: Power Transmission components for everything from the tool room to the production line including key stock, machine keys, tool steel, shims, spacers, and more. Once the step shimming task is complete and the alignment of the machines has been rechecked with all anchor bolts tight, do not neglect to trim off the excess part of the shims protruding out from under the edge of the machine's foot to prevent possible injury. 117 0 obj

<>

endobj

w?'uo@to;[rsD?NMMg1.dON>y~"&Ejwgo@"+ i{%Mwvq0yrxfxKE^LL%gz=Np>2ES;3ZNveGQ4 While we are on the topic of angled feet or irregular surfaces, let us address the topic of "soft" shims for a moment. All of Aloma Shims greater than

1 0 obj startxref

5k=QN,~@$d5N~O#buK?49mwpy*/,lZxo[

@+ SU%&LzG} ["`FlHt!s*M2#6S MHP6{EB*/(ZdKKKH@Xp340a Purchase stainless steel shim stock from Thread Check Inc. <> Contact our knowledgeable sales engineering staff for any questions or assistance regarding our selection of stainless steel shim stock. The best way, of course, would be to re-machine the base plate, sole plate, or undersides of the machine feet in such a way as to eliminate the lack of coplanarity. Never shim more than an overall elevation of .150" in one application. For one thing, you will be able to cut only the thinner thicknesses with scissors or shears, whereas thicker thicknesses (over 0.004") will require using an acetylene torch or a saw, which is labor intensive and presents several safety concerns. xb```,g@

Y8 Some standard shim sizes can also be determined based on standard motor frame numbers. We can also supply special widths and lengths - please contact us direct with your requirements. They are used in automotive body panels, electric motor mounts, and many other applications. <]>>

To calculate the ideal shim thickness, measure the largest air gap with an inside micrometer and divide this gap by five. This leaves us with the only other possible solution: step shimming. <>/A<>/Type/Annot/Rect[448.685 780.743 484.57 771.429]>> 0000002881 00000 n

Step shimming requires several thinner shims to be carefully inserted between the machine's foot and its support surface in such a way that they are offset from one another in step fashion. This can be caused when the feet are accidentally bent, or when the machine is "rolled" to accommodate a horizontal misalignment problem (definitely not a best practice!) 14 0 obj Sandwich thinner shims in between thicker shims to protect them. Shims are used for taking up excessive tolerances and gaps in assemblies.

Shim sizing is often proportional to the size of the anchor bolts. 0000002720 00000 n

Practi-Shim materials are color-coded to provide users with an accurate, reliable recognition of thickness for ease of use. When ordering, shim stock is identified by all three measurements. Get yours today: Power Transmission components for everything from the tool room to the production line including key stock, machine keys, tool steel, shims, spacers, and more. Once the step shimming task is complete and the alignment of the machines has been rechecked with all anchor bolts tight, do not neglect to trim off the excess part of the shims protruding out from under the edge of the machine's foot to prevent possible injury. 117 0 obj

<>

endobj

w?'uo@to;[rsD?NMMg1.dON>y~"&Ejwgo@"+ i{%Mwvq0yrxfxKE^LL%gz=Np>2ES;3ZNveGQ4 While we are on the topic of angled feet or irregular surfaces, let us address the topic of "soft" shims for a moment. All of Aloma Shims greater than