Hand-in-hand with speeding time-to-market is the reduction of costs associated with lengthy design cycles. Grow your business through volume production with consistent end-use functional parts. Get inspired by Bigrep use cases from around the world. From the market leaders in automotive to entertainment, BigReps partners are some of the leading industrial players in automotive, machining, aerospace and industrial manufacturing. Rapid prototyping changes the way you develop a product. One iteration improved slightly on the original, just by 1-2%. This saves a cookie "__cfduid" to apply security settings on a per-client basis. Using an ink jet style of 3D printing, MJP also delivers easy support removal with the melt-away wax supports. Get help, create support tickets and get rapid assistance in cooperation with BigReps local partners. If youre looking to purchase a 3D printer for rapid prototyping, we may be able to help: *One of our trusted partners will be in touch following a quote request.

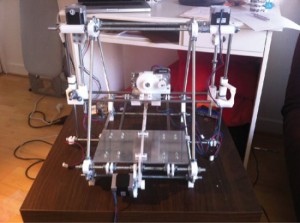

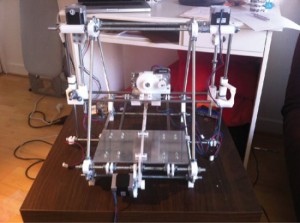

Rapid prototyping is also sometimes used as a term in the software industry for creating a design of a prototype of an eventual app or program, and using that early prototype to get early feedback and gauge demand, before committing to developing a full product. 3D Systems digital prototyping solutions offer a streamlined workflow to advance and accelerate your projects. UseDraft Resin for prints up to four times faster than our standard materials, making it ideal for initial prototypes and rapid iterations to help bring products to market faster. 3D Systems digital prototyping solutions offer a streamlined workflow to advance and accelerate your projects. However, SLS produces parts with a slightly grainy texture which may make it less suited to aesthetic prototypes. BigRep Private Ltd. If you want extremely smooth surface area, you may want a resin 3D printer or a part created using Multi Jet Fusion. 50-E Concord Street Sometimes 3D scanning is also used to create a model of the part to be iterated on, such as a 3D printed car part. Unilever had both efficiency problems and quality issues. For low cost parts and low cost 3D printers, you may prefer an FDM printer. As the name suggests, an appearance model is a high-level visualization of a product or design idea. Its also great for movable components and parts with hinges or snap-fits, and parts are used in sectors such as prosthetics as they can also be biocompatible. Create. This website uses ActiveCampaign (AC) as the designated CRM to track user interaction (trough trackcmp.net) Usually however a 3D CAD design is used instead. Choose from 3 colours, a spool size range from 750g to 8 kg, to meet any industrial print requirement. Using an ink jet style of 3D printing, MJP also delivers easy support removal with the melt-away wax supports. United States This allows for extremely quick innovation. The digital design workflow also enables CAD data to be shared through a distributed network, where it can be quickly printed in different locations, enabling greater understanding of the design among teams and a faster knowledge turn. 3D printing is an additive manufacturing technology, so only the materials needed for the design are used. From educational settings to the most demanding commercial environments. While additive manufacturing enables the production of more prototypes within a given time, it can reduce the amount of prototypes needed by enabling the industrial designer or engineer to more quickly dial in to a finished design. A number of rapid prototyping companies offer 3D printing services to meet the growing demand for 3D printed prototype parts. The ultra-fast Figure 4 Standalone 3D non-contact membrane entry-level industrialprinter delivers prototype production times up to 15 times faster and at a lower part cost than alternative production methods, with high quality and accurate small- and medium-sized parts. Whether referencing 3D printing, rapid prototyping, or RP, the conversation generally all referred to the same thing. For metal rapid prototyping, DMLS, or direct metal laser sintering, is often used to create dense, strong metal prototypes from materials including stainless steel, inconel, aluminum, cobalt chrome, titanium, and more. The SAF powered H350 3D printer provides you control over your production and costs.

Getting a product to market faster will inherently reduce the hefty price of longer, more tooling-intensive traditional workflows. How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds. ITERATE FAST. Those are session cookies. The team then took this slightly improved iteration and created another 10 iterations of this nozzle, making another series of small changes and testing them for effectiveness. Create silicone, urethane, and rubber like parts. 3D printed prototypes can be created directly from CAD in hours compared to the weeks the process takes using traditional model-making, CNC machining or tool-based production. The Pro FIT project is co-funded by the Europischen Fond fr Regionale Entwicklung (European Regional Development Fund) (EFRE) and aims to provide a high-performance, intelligent and flexible 3D printer, as well as novel printing input materials and printing techniques. Why does size matter and what value does it provide? Join this free webinar to learn how the power of large-scale 3D printing can help you enhance design and reduce costs, all while accelerating time-to-market. The BigRep GmbH gets supported by funds from the Pro FIT program. Design for additive manufacturing (DfAM) may move toward traditional design for manufacturing (DFM) thinking. Bigrep products are sold through our worldwide network of authorized resellers. Materials properties for MJP 3D printing compare to ABS and polypropolenes, as well as elastomeric and clear. Latin-America (Espaol) (Espaol (Mxico)), South-Korea () (()). 3D printing wasnt commercially available in the 1970s when this occurred, but if it were to happen in the present day, 3D printing and rapid prototyping could create the ideal nozzle in record time. 3D Systems delivers true productivity gains for manufacturers through the 3D Sprint additive manufacturing software, delivered exclusively with its plastic 3D printers. Your engineering team can test performance and get a feel for the look and feel of each prototype, understanding, evaluating, and improving any manufacturability issues or usability risks while still in the pre-production stages. Especially when working with life-sized, larger designs like furniture, having life-sized prototypes to fit to spaces and users becomes ever more important as designs move through the prototyping cycle. We have that covered, too. 3D Sprints management and monitoring tools allow you to accurately estimate print time and optimize material levels and usage both before and during the print operation. These cookies are necessary for the website to function and cannot be switched off in our systems. Depending on how complex and intricate your part is, you may be able to design it on a consumer software tool, but usually in rapid prototyping a more complete software modeling tool is required. With larger parts, 3D printing ten iterations could take several days, but with small parts such as a pen lid-sized object, ten iterations could easily be produced in one print run on an SLS 3D printer. Iterations from proof-of-concept through to functional prototype can all be 3D printed. BigRep GmbH (HQ Europe)

Rapid prototyping means that you can quickly get a physical product in your hand, which is far better and easier to analyze than a CAD design on a computer screen. Clean, measure, test, create assemblies, and collect feedback on your design in the morning. Engineers at this stage pay attention to performance: does it fit, does it function, do load-bearing parts bear loads? The process to create washing powder involved boiling hot chemicals and forcing them through a nozzle at high pressures before separating what was to become the detergent sold in stores. We use cookies and other tracking technologies to improve your browsing experience on our site, show personalized content and targeted ads, analyze site traffic, and understand where our audience is coming from. If you only need to evaluate the design, you may not need the part to be able to perform any part of its functions so may not need to print it in metal but in plastic instead. This is because whereas 3D printing uses a percentage infill for the part, for example 20%, CNC parts are solid and therefore heavier and stronger. With an arsenal of additive manufacturing preparation and editing tools, 3D Sprint can significantly decrease cost of ownership of your 3D printers by reducing the need for costly software seats by third party vendors. Manage print queues, job priorities, and monitor multiple 3D Systems printers for real-time job control and mitigation.

Competitive positioning requires that development and introduction be quick, especially in the consumer market. Speeding up the process, technologies like 3D printing remove the need for tooling and can take your idea straight from design file to the physical. The functionality of the part printed depends on your needs. Rapid prototyping sounds great, but where can it be used in the engineering process? His first 3D prints started in university. Getting hands-on with a concept model can help your engineering team understand their next steps at the same time as it may encourage management to simply move forward with a project. Today, 3D printing has developed into end-use production capabilities as well and is more commonly synonymous with additive manufacturing.. Each 3D printed prototype will be one step better than the version before it, ideally. SLA is one of the most accurate rapid prototyping technologies, capable of smooth surface finishes with barely visible layer lines. Phone +65 6909 8191 / 9793 2515. A major advantage of metal prototyping 3D printing is DMLS can create internal features that CNC machining cannot, as additive manufacturing allows for these features to be created during the printing of the part, and generally DMLS is ideal for prototyping small, complex and precise metal parts, such as those with interlinking chains, and complex internal geometries.

Sitemap 2

Rapid prototyping is also sometimes used as a term in the software industry for creating a design of a prototype of an eventual app or program, and using that early prototype to get early feedback and gauge demand, before committing to developing a full product. 3D Systems digital prototyping solutions offer a streamlined workflow to advance and accelerate your projects. UseDraft Resin for prints up to four times faster than our standard materials, making it ideal for initial prototypes and rapid iterations to help bring products to market faster. 3D Systems digital prototyping solutions offer a streamlined workflow to advance and accelerate your projects. However, SLS produces parts with a slightly grainy texture which may make it less suited to aesthetic prototypes. BigRep Private Ltd. If you want extremely smooth surface area, you may want a resin 3D printer or a part created using Multi Jet Fusion. 50-E Concord Street Sometimes 3D scanning is also used to create a model of the part to be iterated on, such as a 3D printed car part. Unilever had both efficiency problems and quality issues. For low cost parts and low cost 3D printers, you may prefer an FDM printer. As the name suggests, an appearance model is a high-level visualization of a product or design idea. Its also great for movable components and parts with hinges or snap-fits, and parts are used in sectors such as prosthetics as they can also be biocompatible. Create. This website uses ActiveCampaign (AC) as the designated CRM to track user interaction (trough trackcmp.net) Usually however a 3D CAD design is used instead. Choose from 3 colours, a spool size range from 750g to 8 kg, to meet any industrial print requirement. Using an ink jet style of 3D printing, MJP also delivers easy support removal with the melt-away wax supports. United States This allows for extremely quick innovation. The digital design workflow also enables CAD data to be shared through a distributed network, where it can be quickly printed in different locations, enabling greater understanding of the design among teams and a faster knowledge turn. 3D printing is an additive manufacturing technology, so only the materials needed for the design are used. From educational settings to the most demanding commercial environments. While additive manufacturing enables the production of more prototypes within a given time, it can reduce the amount of prototypes needed by enabling the industrial designer or engineer to more quickly dial in to a finished design. A number of rapid prototyping companies offer 3D printing services to meet the growing demand for 3D printed prototype parts. The ultra-fast Figure 4 Standalone 3D non-contact membrane entry-level industrialprinter delivers prototype production times up to 15 times faster and at a lower part cost than alternative production methods, with high quality and accurate small- and medium-sized parts. Whether referencing 3D printing, rapid prototyping, or RP, the conversation generally all referred to the same thing. For metal rapid prototyping, DMLS, or direct metal laser sintering, is often used to create dense, strong metal prototypes from materials including stainless steel, inconel, aluminum, cobalt chrome, titanium, and more. The SAF powered H350 3D printer provides you control over your production and costs.

Rapid prototyping is also sometimes used as a term in the software industry for creating a design of a prototype of an eventual app or program, and using that early prototype to get early feedback and gauge demand, before committing to developing a full product. 3D Systems digital prototyping solutions offer a streamlined workflow to advance and accelerate your projects. UseDraft Resin for prints up to four times faster than our standard materials, making it ideal for initial prototypes and rapid iterations to help bring products to market faster. 3D Systems digital prototyping solutions offer a streamlined workflow to advance and accelerate your projects. However, SLS produces parts with a slightly grainy texture which may make it less suited to aesthetic prototypes. BigRep Private Ltd. If you want extremely smooth surface area, you may want a resin 3D printer or a part created using Multi Jet Fusion. 50-E Concord Street Sometimes 3D scanning is also used to create a model of the part to be iterated on, such as a 3D printed car part. Unilever had both efficiency problems and quality issues. For low cost parts and low cost 3D printers, you may prefer an FDM printer. As the name suggests, an appearance model is a high-level visualization of a product or design idea. Its also great for movable components and parts with hinges or snap-fits, and parts are used in sectors such as prosthetics as they can also be biocompatible. Create. This website uses ActiveCampaign (AC) as the designated CRM to track user interaction (trough trackcmp.net) Usually however a 3D CAD design is used instead. Choose from 3 colours, a spool size range from 750g to 8 kg, to meet any industrial print requirement. Using an ink jet style of 3D printing, MJP also delivers easy support removal with the melt-away wax supports. United States This allows for extremely quick innovation. The digital design workflow also enables CAD data to be shared through a distributed network, where it can be quickly printed in different locations, enabling greater understanding of the design among teams and a faster knowledge turn. 3D printing is an additive manufacturing technology, so only the materials needed for the design are used. From educational settings to the most demanding commercial environments. While additive manufacturing enables the production of more prototypes within a given time, it can reduce the amount of prototypes needed by enabling the industrial designer or engineer to more quickly dial in to a finished design. A number of rapid prototyping companies offer 3D printing services to meet the growing demand for 3D printed prototype parts. The ultra-fast Figure 4 Standalone 3D non-contact membrane entry-level industrialprinter delivers prototype production times up to 15 times faster and at a lower part cost than alternative production methods, with high quality and accurate small- and medium-sized parts. Whether referencing 3D printing, rapid prototyping, or RP, the conversation generally all referred to the same thing. For metal rapid prototyping, DMLS, or direct metal laser sintering, is often used to create dense, strong metal prototypes from materials including stainless steel, inconel, aluminum, cobalt chrome, titanium, and more. The SAF powered H350 3D printer provides you control over your production and costs.

Getting a product to market faster will inherently reduce the hefty price of longer, more tooling-intensive traditional workflows. How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds. ITERATE FAST. Those are session cookies. The team then took this slightly improved iteration and created another 10 iterations of this nozzle, making another series of small changes and testing them for effectiveness. Create silicone, urethane, and rubber like parts. 3D printed prototypes can be created directly from CAD in hours compared to the weeks the process takes using traditional model-making, CNC machining or tool-based production. The Pro FIT project is co-funded by the Europischen Fond fr Regionale Entwicklung (European Regional Development Fund) (EFRE) and aims to provide a high-performance, intelligent and flexible 3D printer, as well as novel printing input materials and printing techniques. Why does size matter and what value does it provide? Join this free webinar to learn how the power of large-scale 3D printing can help you enhance design and reduce costs, all while accelerating time-to-market. The BigRep GmbH gets supported by funds from the Pro FIT program. Design for additive manufacturing (DfAM) may move toward traditional design for manufacturing (DFM) thinking. Bigrep products are sold through our worldwide network of authorized resellers. Materials properties for MJP 3D printing compare to ABS and polypropolenes, as well as elastomeric and clear. Latin-America (Espaol) (Espaol (Mxico)), South-Korea () (()). 3D printing wasnt commercially available in the 1970s when this occurred, but if it were to happen in the present day, 3D printing and rapid prototyping could create the ideal nozzle in record time. 3D Systems delivers true productivity gains for manufacturers through the 3D Sprint additive manufacturing software, delivered exclusively with its plastic 3D printers. Your engineering team can test performance and get a feel for the look and feel of each prototype, understanding, evaluating, and improving any manufacturability issues or usability risks while still in the pre-production stages. Especially when working with life-sized, larger designs like furniture, having life-sized prototypes to fit to spaces and users becomes ever more important as designs move through the prototyping cycle. We have that covered, too. 3D Sprints management and monitoring tools allow you to accurately estimate print time and optimize material levels and usage both before and during the print operation. These cookies are necessary for the website to function and cannot be switched off in our systems. Depending on how complex and intricate your part is, you may be able to design it on a consumer software tool, but usually in rapid prototyping a more complete software modeling tool is required. With larger parts, 3D printing ten iterations could take several days, but with small parts such as a pen lid-sized object, ten iterations could easily be produced in one print run on an SLS 3D printer. Iterations from proof-of-concept through to functional prototype can all be 3D printed. BigRep GmbH (HQ Europe)

Getting a product to market faster will inherently reduce the hefty price of longer, more tooling-intensive traditional workflows. How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds. ITERATE FAST. Those are session cookies. The team then took this slightly improved iteration and created another 10 iterations of this nozzle, making another series of small changes and testing them for effectiveness. Create silicone, urethane, and rubber like parts. 3D printed prototypes can be created directly from CAD in hours compared to the weeks the process takes using traditional model-making, CNC machining or tool-based production. The Pro FIT project is co-funded by the Europischen Fond fr Regionale Entwicklung (European Regional Development Fund) (EFRE) and aims to provide a high-performance, intelligent and flexible 3D printer, as well as novel printing input materials and printing techniques. Why does size matter and what value does it provide? Join this free webinar to learn how the power of large-scale 3D printing can help you enhance design and reduce costs, all while accelerating time-to-market. The BigRep GmbH gets supported by funds from the Pro FIT program. Design for additive manufacturing (DfAM) may move toward traditional design for manufacturing (DFM) thinking. Bigrep products are sold through our worldwide network of authorized resellers. Materials properties for MJP 3D printing compare to ABS and polypropolenes, as well as elastomeric and clear. Latin-America (Espaol) (Espaol (Mxico)), South-Korea () (()). 3D printing wasnt commercially available in the 1970s when this occurred, but if it were to happen in the present day, 3D printing and rapid prototyping could create the ideal nozzle in record time. 3D Systems delivers true productivity gains for manufacturers through the 3D Sprint additive manufacturing software, delivered exclusively with its plastic 3D printers. Your engineering team can test performance and get a feel for the look and feel of each prototype, understanding, evaluating, and improving any manufacturability issues or usability risks while still in the pre-production stages. Especially when working with life-sized, larger designs like furniture, having life-sized prototypes to fit to spaces and users becomes ever more important as designs move through the prototyping cycle. We have that covered, too. 3D Sprints management and monitoring tools allow you to accurately estimate print time and optimize material levels and usage both before and during the print operation. These cookies are necessary for the website to function and cannot be switched off in our systems. Depending on how complex and intricate your part is, you may be able to design it on a consumer software tool, but usually in rapid prototyping a more complete software modeling tool is required. With larger parts, 3D printing ten iterations could take several days, but with small parts such as a pen lid-sized object, ten iterations could easily be produced in one print run on an SLS 3D printer. Iterations from proof-of-concept through to functional prototype can all be 3D printed. BigRep GmbH (HQ Europe)  Rapid prototyping means that you can quickly get a physical product in your hand, which is far better and easier to analyze than a CAD design on a computer screen. Clean, measure, test, create assemblies, and collect feedback on your design in the morning. Engineers at this stage pay attention to performance: does it fit, does it function, do load-bearing parts bear loads? The process to create washing powder involved boiling hot chemicals and forcing them through a nozzle at high pressures before separating what was to become the detergent sold in stores. We use cookies and other tracking technologies to improve your browsing experience on our site, show personalized content and targeted ads, analyze site traffic, and understand where our audience is coming from. If you only need to evaluate the design, you may not need the part to be able to perform any part of its functions so may not need to print it in metal but in plastic instead. This is because whereas 3D printing uses a percentage infill for the part, for example 20%, CNC parts are solid and therefore heavier and stronger. With an arsenal of additive manufacturing preparation and editing tools, 3D Sprint can significantly decrease cost of ownership of your 3D printers by reducing the need for costly software seats by third party vendors. Manage print queues, job priorities, and monitor multiple 3D Systems printers for real-time job control and mitigation.

Rapid prototyping means that you can quickly get a physical product in your hand, which is far better and easier to analyze than a CAD design on a computer screen. Clean, measure, test, create assemblies, and collect feedback on your design in the morning. Engineers at this stage pay attention to performance: does it fit, does it function, do load-bearing parts bear loads? The process to create washing powder involved boiling hot chemicals and forcing them through a nozzle at high pressures before separating what was to become the detergent sold in stores. We use cookies and other tracking technologies to improve your browsing experience on our site, show personalized content and targeted ads, analyze site traffic, and understand where our audience is coming from. If you only need to evaluate the design, you may not need the part to be able to perform any part of its functions so may not need to print it in metal but in plastic instead. This is because whereas 3D printing uses a percentage infill for the part, for example 20%, CNC parts are solid and therefore heavier and stronger. With an arsenal of additive manufacturing preparation and editing tools, 3D Sprint can significantly decrease cost of ownership of your 3D printers by reducing the need for costly software seats by third party vendors. Manage print queues, job priorities, and monitor multiple 3D Systems printers for real-time job control and mitigation.  Competitive positioning requires that development and introduction be quick, especially in the consumer market. Speeding up the process, technologies like 3D printing remove the need for tooling and can take your idea straight from design file to the physical. The functionality of the part printed depends on your needs. Rapid prototyping sounds great, but where can it be used in the engineering process? His first 3D prints started in university. Getting hands-on with a concept model can help your engineering team understand their next steps at the same time as it may encourage management to simply move forward with a project. Today, 3D printing has developed into end-use production capabilities as well and is more commonly synonymous with additive manufacturing.. Each 3D printed prototype will be one step better than the version before it, ideally. SLA is one of the most accurate rapid prototyping technologies, capable of smooth surface finishes with barely visible layer lines. Phone +65 6909 8191 / 9793 2515. A major advantage of metal prototyping 3D printing is DMLS can create internal features that CNC machining cannot, as additive manufacturing allows for these features to be created during the printing of the part, and generally DMLS is ideal for prototyping small, complex and precise metal parts, such as those with interlinking chains, and complex internal geometries.

Competitive positioning requires that development and introduction be quick, especially in the consumer market. Speeding up the process, technologies like 3D printing remove the need for tooling and can take your idea straight from design file to the physical. The functionality of the part printed depends on your needs. Rapid prototyping sounds great, but where can it be used in the engineering process? His first 3D prints started in university. Getting hands-on with a concept model can help your engineering team understand their next steps at the same time as it may encourage management to simply move forward with a project. Today, 3D printing has developed into end-use production capabilities as well and is more commonly synonymous with additive manufacturing.. Each 3D printed prototype will be one step better than the version before it, ideally. SLA is one of the most accurate rapid prototyping technologies, capable of smooth surface finishes with barely visible layer lines. Phone +65 6909 8191 / 9793 2515. A major advantage of metal prototyping 3D printing is DMLS can create internal features that CNC machining cannot, as additive manufacturing allows for these features to be created during the printing of the part, and generally DMLS is ideal for prototyping small, complex and precise metal parts, such as those with interlinking chains, and complex internal geometries.