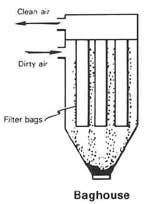

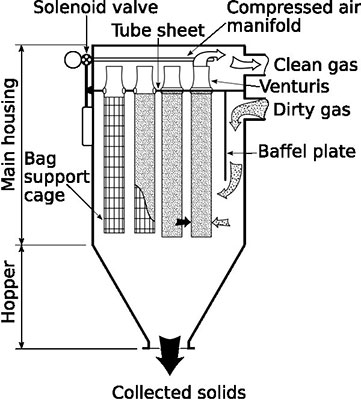

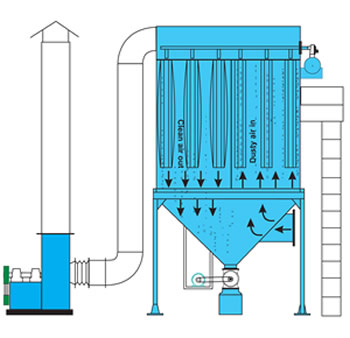

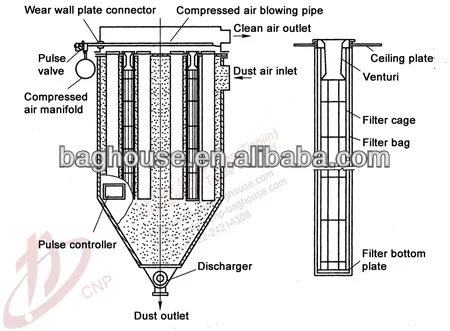

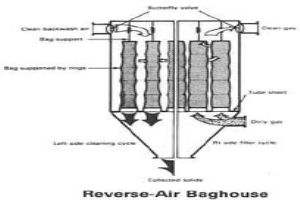

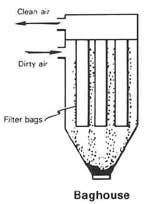

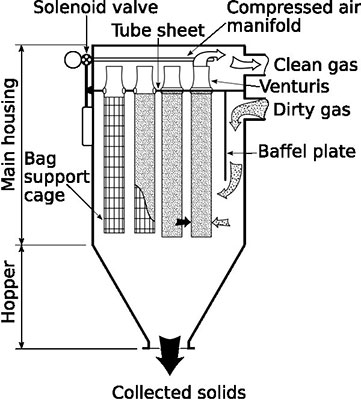

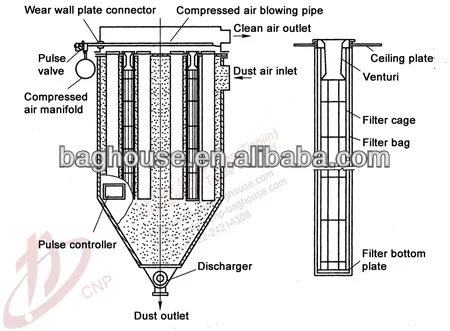

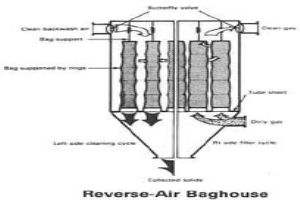

PPC type airbag pulse bag filter is a new product introduced by the American Fule Company. What is working principle of venture of dust collector baghouse filter bag cages? Baghouse dust collectors are considered to be an air treatment device that allows filtering the air by bags made of different materials that have to be periodically cleaned to take away the accumulated dust. In reverse-air baghouses, the bags are fastened onto a cell plate at the bottom of the baghouse and suspended from an adjustable hanger frame at the top. Upon entry, the larger particulate matter drops directly into the hopper below, due to a decrease in conveying velocity. Pulse-jet filter bag solutions. The design of the baghouse collector is developed to allow a large amount of air or gas passing through it, which is sent to the baghouses of dust collectors that hold dust particles. In some systems, an electrostatic charge is placed on the particles and/or the filter to capture even more dust.

FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. in / sq.

Efficiency. Product Categories. Working Design Considerations And Maintenance Of Bag Type. High (typically >99.5%) Highly dependent on application: Maintenance. Baghouse Filter - an overview | ScienceDirect Topics. Using a Triboelectric Broken Bag Detector as Early Warning. The material from which the sleeve is made is selected depending on the conditions of its Bag filter is the most widely used air pollution prevention and control dust, but also the most efficient dust precipitator.

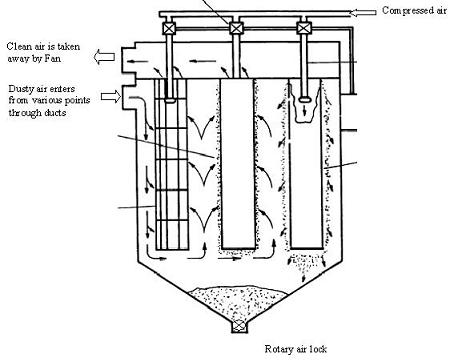

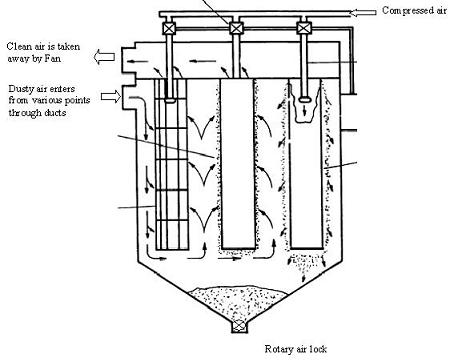

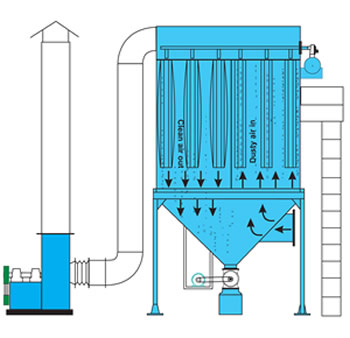

The main privileges of bag filters are efficiency, profitability, reliability and, accordingly, durability. Filter for cleaning the compressed air is installed in dust collection systems and aspiration. The main element of the bag filter is the filtering sleeves, which require replacement and often wear out. Reverse air cleaning High Pressure, Low Volume Medium Pressure Low Pressure. To do that it must overcome the resistance to flow created by the filters and the ductwork. The principle of baghouse dust collectors operation. Product Categories. In principle, dust may be collected on the inside or outside surface, with airflow from inside out or outside in, respectively. Filter bags, for gas filtration, are mainly used in large numbers in baghouses (fabric filters) for the filtration of solidgas suspensions with a reasonably high solids content (referred to as the dust load). Baghouse Filter June 01, 2022 Baghouse Dust Collector for Sale. System equipment (1) LCMD-type off-line deindustrialization and low pressure pulse bag dust collector frame structure and body boxes - structural frame is used to support the body of a dust collector, ash bunker and ash transport equipment, etc. They work on the principle of vacuum cleaners (Nicol, 2013) the flue gas passes through a filter, which rejects particles that are too large to pass through. 22.3.3 Fabric filters. FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. Bag Filter Working Principle. The working mechanism of the bag filter is that after the dust-laden flue gas enters the dust collector through the duct through the wind force of the induced draft fan, it passes through the first-level baffle (gravity sedimentation), the large specific gravity dust is intercepted and then settles into the ash hopper.

Fly ash is collected by the bag/filter itself, or by the accumulated Bag filter working principle: Bag filter is typically used in applications requiring gross particulate removal. 144 sq. The bag textile cloth made of felt or non Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. Filter for cleaning the compressed air is installed in dust collection systems and aspiration. National Filter Media has been around since 1906 and grown to one of the largest filter media companies in the world. Working Principle Of Vertical Raw Mill They work on the principle of vacuum cleaners (Nicol, 2013); the flue gas passes through a filter, which rejects particles that are too large to pass through. Conversely, static pressure or static resistance is a measurement of resistance generated by the ductwork and the filters in baghouse. The design and principle of operation of the baghouse filter allow you to take advantage of a number of functional and technological advantages: 1.Ease of installation and operation of the air purification system; 2.The possibility of continuous operation as part of the ventilation system; 3.Easy maintenance and minimal maintenance costs;

Enter (Bag Diameter Length of Cages # of Bags). ft. Then Click on Calculate To Find the Cloth Area Fans on the outside of the housing blow the dirty or polluted air through the filters, capturing the suspended particulate matter and solids on the bags and pushing clean air through the outlet. While filtering, a baghouse bag allows the formation of a layer of particulate matter on its surface, called a dust cake. Bag Filter Working Principle. Baghouse Basics operation and maintenance Presented by: Brent McIntosh Baghouse Applications Dust Control Found at end of dust control system to filter air Bin/Silo Venting

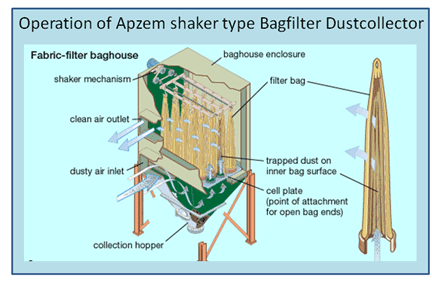

Moderate (if correctly sized/designed) exiting baghouse to atmosphere. This type of dust remover can be widely used in glass installation, warehouse roof, cooked cooling machine and mill dust collection system in cement plants. Fabric Filter Baghouse Consulting And Design Case Studies. The filter bag generates rapid expansion and impact vibration from the mouth of the bag to the bottom, resulting in a strong cleaning action, shaking the filter Dust on the bag. Bag Filter working animation. Keeping the air clean of dust is crucial for environmental and human protection but is also very important for proper production.

100 gm Clean gas conc.

The first series of bags that the air passes through works to accumulate the dust particulate.

Lecture 4 Design Of Fabric Filter NPTEL. The baghouse dust collector for ventilation and air treatment is one of the most effective air treatment devices capable of catching air pollutants and used for cleaning gases and gas mixtures. ; The box body includes the upper body of the box, the The particles are captured within the filter and removed before clean gas is emitted. Main Parts of Bag House Filter . Fabric filter. Baghouse filter vs Cyclone. The air charged of dust is suctioned in the hopper or directly in the filter body by means of an aerodynamic inlet duct designed to obtain a uniform info@senotay.com +86-15831871808. Robinsons Filter Solutions sells a wide range of aftermarket baghouse filter bags, dust filter socks and dust collector bags to fit OEM baghouse systems including Nordson, Donaldson Torit, Murphy, MacDonald Steel and Canoblast, among many others. The working principle of an ESP consists of the application between a discharge electrode and a collection electrode (usually known as plates) of a sufficiently high electric voltage difference Baghouse filters require regular replacement, which can make them expensive to operate.

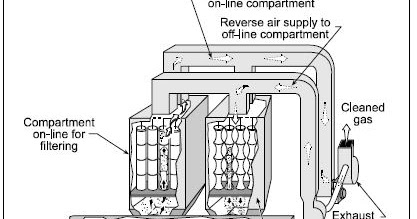

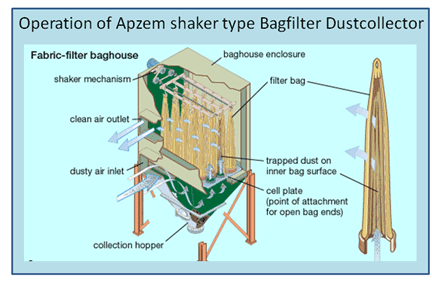

The longer a leak persists the worse it becomes, often quickly causing a plant to exceed its maximum PM 2.5 emissions limits set out in its air permit. Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Shaker Baghouse. The baghouse filter may also be equipped with a mechanism that can remove dust from the air inside it. 1 electromagnetic pulse valve. Product Categories. Reverse air baghouse optimization with GORE LOW DRAG Filter Bags Astec Inc. - Manufacturers of continuous and batch-process The working principle of Senotay baghouse filter is a filtering process and a cleaning process. baghouse and then through the filters and out to exhaust. due to the lower air-to-cloth ratio achieved with the reverse air baghouse working principle. News; Service; Resource; Contact Us Fabric Filter Baghouse Consulting And Design Case Studies.

Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant , Find Complete Details about Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant,Baghouse Type Bag Filter Dust Collector,Industrial Baghouse Dust Collector,Baghouse Dust Collector from Dust Collector Supplier or Manufacturer-Botou Ever Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant , Find Complete Details about Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant,Baghouse Type Bag Filter Dust Collector,Industrial Baghouse Dust Collector,Baghouse Dust Collector from Dust Collector Supplier or Manufacturer-Botou Ever

The airstream enters below the bag filters and is pulled up through the filtering system. In pharmaceutical production, very potent drugs such as hormones, vitamins, antibiotics, etc generate a lot of dust during processing which may be life-threatening to the operators. Dust every small particle such us cement, ash, sawdust or even sugar, flour etc. In reverse-air baghouses, the bags are fastened onto a cell plate at the bottom of the baghouse and suspended from an adjustable hanger frame at the top. Baghouse. Pulse-jet baghouses are the most common type of nonwoven filter. It is controlled by the electric signals from the pulse -jet control device. suspended in the air. Produced water or brines from shale gas Bag Filter Pulse Jet Valve Application: Pulse Jet Valve, also called diaphragm valve acts as a switch for compressed air in the dust clean blowing system for pulse bag filters. July 30, 2019. Baghouse works principle. A baghouse also known as a baghouse filter bag filter or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. New Baghouse Filter Bags. This type of reverse air baghouse generates a lower pressure than the compressed air pulses of a pulse jet.

Dust-filled air is pushed via hoppers through the fabric bags during the process.

During a shaker baghouse, filter bags are hung and tensioned from the highest of the filter housing and attached with rock bottom open, to the tube sheet. Buy Baghouse Filter from Machine Business Opportunities, Baghouse Filter specifications: Baghouse Filter, 5.5-7kg/t, 20-320T/H, ISO9001, ISO14001 CE,Gost, Baghouse Filter 20 years.

Baghouse Fabric Filter Dust Collector Foundry Use Dust Removal Equipment . Metallurgy Pulse Baghouse Fabric Filter 0.4Mpa Dust Collector Equipment . Whether you are using pulse-jet baghouse technology or reverse air filter bags, you need to be confident that your process meets the regulations around particulate matter compliance testing. As with the reverse air filters, dust, dirt, particulates, and contaminants collect on the outside of the bag filter and are removed by bursts of compressed air that moves along the length of the bag. Baghouse filter working principle pdf 4. Most leaking baghouse filters begin as small holes or rips that overtime become worse and worse. 10 mgm n.c. dry Leading process filter technologies by Intensiv-Filter Filter area 13.700 m 4 Enhanced Energy Efficiency Solutions for Bag Filters 1 Introduction. FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. The working principle of Senotay baghouse filter is a filtering process and a cleaning process. With so many different types of baghouse filter fabrics and treatments options to choose from, its important to know which is the best fit for your specific application. Steady air circulation continuously pulls air through the filter bags. Working principle of baghouse dust collector 2020-07-03 Industrial Dust Collectors Industrial vacuum cleaners are the industrial dust collectors used in industrial applications for the collection, absorption, production, operation, and transportation of waste materials such as waste media particles, dust, smoke, oil and water. Posted on 2015-10-01 by shengjie.

Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Lecture 4 Design Of Fabric Filter NPTEL. Figure 5.33 shows the two possible modes of operation for baghouse filters. Inside-out filtration implies that the gas passes through the filter from the inside. This blows up the bag filters to their maximum volume and produces the cake on the inside of the bag. Outside-in operation involves that the gas

The baghouse or fabric filter can be safely operated only within the temperature range specified by the manufacturer. Air filtration technology is the bag filter working principle. baghouse, cleaning can be carried out while the baghouse is on-line (filtering) or is off-line (in isolation). Choosing the correct baghouse filter will maximize performance, increase filter life, reduce system downtime and save you money. Bag Cleaning Systems.

This paper mainly focuses on the analysis of working principles, computer simulation of the operation and design consideration of the inverter for grid-connected applications.. Baghouse Filter Basics.

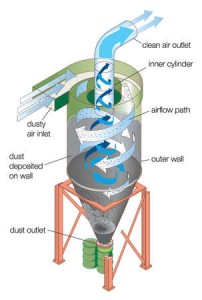

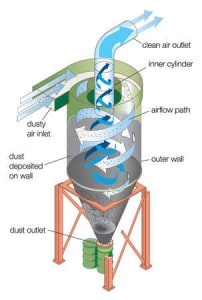

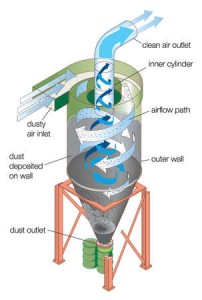

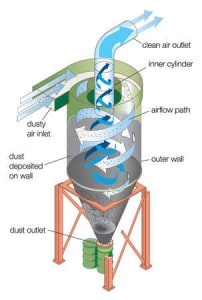

Bag filter working principle. The Reverse Air Bag House (RABH) is a custom-built filter, designed for cleaning gases with typically high flow rates and high temperatures. This paper mainly focuses on the analysis of working principles, computer simulation of the operation and design consideration of the inverter for grid-connected applications.. As well, we can have custom baghouse filter bags manufactured to meet your specific info@senotay.com 86 13932733791. This also is measured in inches of water gauge. Baghouse Filters. Baghouse Filter An Overview Sciencedirect Topics. 3. Fabric filter. Catching a leak quickly is crucial. A cyclone is a centrifugal separator in which particles, due to their mass, are pushed to the outer edges as a result of centrifugal force. It is controlled by the electric signals from the pulse -jet control device. A pulse-jet baghouse is the most versatile type of baghouse, because it can use filter bags with a variety of media and finishes. Working principle. Depending on the type of Baghouse Filter, the nonwoven filter is used to clean specific types of air. Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8.

Bag filters are used in many industries where filtration is less critical and the bags can be easily disposed.

Baghouse filters are the most common way to contain dust from industrial emissions. Reverse air baghouse optimization with GORE LOW DRAG Filter Bags Astec Inc. - Manufacturers of continuous and batch-process. When the dust-containing gas passes through the filter media, the dust is stopped on its surface and the clean air is discharged through the gaps of the filter media. The working mechanism of the bag filter is that after the dust-laden flue gas enters the dust collector through the duct through the wind force of the induced draft fan, it passes through the first-level baffle (gravity sedimentation), the large specific gravity dust is intercepted and then settles into the ash hopper.

Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Filter bags are made of polypropylene or polyester Bag Filters Cyclone cum Bag Filters Air Pollution Control Re: Bag filter design and working principle Dear Sir, would be please send me the excel sheet or any soft copy for designing procedure of bag filter My E-mail ID:- [email protected] or [email protected] I ,

Baghouse Fabric Filter Dust Collector Foundry Use Dust Removal Equipment . Baghouse dust collectors filter dust particles from the ambient airstream using long fabric bags (or tubes). The valve induces air several times the amount of air injected into the filter bag through the nozzle on the blowing pipe to form an air wave.

Raw gas conc.

Baghouse.com Control air pollution with baghouse filter bags. Robinsons Filter Solutions sells a wide range of aftermarket baghouse filter bags, dust filter socks and dust collector bags to fit OEM baghouse systems including Nordson, Donaldson Torit, Murphy, MacDonald Steel and Canoblast, among many others. As well, we can have custom baghouse filter bags manufactured to meet your specific The working principle is adopting solenoid valve to control the cylinder and the top door. The main element of the bag filter is the filtering sleeves, which require replacement and often wear out. Baghouse dust collectors offer a comparatively inexpensive method of collecting solid particles from an air or gas stream. Baghouse Filter - an overview | ScienceDirect Topics. Bag filter working principle: Bag filter is typically used in applications requiring gross particulate removal. Dust Collection Technical Handbook National Filter Media. System equipment (1) LCMD-type off-line deindustrialization and low pressure pulse bag dust collector frame structure and body boxes - structural frame is used to support the body of a dust collector, ash bunker and ash transport equipment, etc. Filter bags are made of polypropylene or polyester Bag Filters Cyclone cum Bag Filters Air Pollution Control The main privileges of bag filters are efficiency, profitability, reliability and, accordingly, durability. 2 Depending on the type of installation, the baghouse dust collectors can also be installed horizontally so that the maximum amount of air passes through them. The working principle of Senotay baghouse filter is a filtering process and a cleaning process. Thomas H. Wines, Saeid Mokhatab, in Contamination Control in the Natural Gas Industry, 2022 4.6.6 Liquid bag filters. Pulse-jet filter bags can be manufactured from most available felt or woven filter medias. The polluted air will move through a series of filters throughout a dust collector in the baghouse system. For cleaning, a fan rotates over the bags, blowing reverse air into them to remove dust.

It is suitable for trapping a small, dry, non-fibrous dust. Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. A Baghouse Filter is a high-efficiency filter.

Baghouse is a dry dust filter device. The baghouse or fabric filter can be safely operated only within the temperature range specified by the manufacturer. Baghouse filters and cartridges filters work thanks to the filtration principle by micro-perforated textile, made in the form of cylindrical bags or pleated cartridges that are fixed to the filter structure and supported by metal cages. We know dust collection. A shaker baghouse, as the name suggests, mechanically disposes of collected dust by shaking it out of the bags into a collection hopper at the bottom of the baghouse. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. Venturi is short for venture tube, the working principle of venturi is that when the air blows through the barrier, the pressure near the port above the leeward side of the barrier is relatively low, thereby producing adsorption and causing air flow. Bag Filter Pulse Jet Valve Application: Pulse Jet Valve, also called diaphragm valve acts as a switch for compressed air in the dust clean blowing system for pulse bag filters. They work on the principle of vacuum cleaners (Nicol, 2013); the flue gas passes through a filter, which rejects particles that are too large to pass through. Pulse-jet filter bags are July 30, 2019. Fluctuation outside of these limits even for a small period, can damage the bags. ; The box body includes the upper body of the box, the Cyclone. Working Design Considerations And Maintenance Of Bag Type. How It Works. Bag Filter - Principle, Construction, Working, and More The bag filter is a mechanical device used in the quality of air in pharmaceutical production and other allied areas. Process filter kiln and rawmeal mill dedusting - France Volume flow 1.000.000 m h n.c.. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. 22.3.3 Fabric filters. Nowadays, the popularity of cartridge dust collectors continues The baghouse dust collector for ventilation and air treatment is one of the most effective air treatment devices capable of catching air pollutants and used for cleaning gases and gas mixtures. Baghouse filter working principle pdf 4. The dirty gas stream enters the baghouse either via an inlet air plenum or directly into the hopper. Air treatment devices are widely used in industry for accurate cleaning of ventilation air from dust particles, as well as for industrial and sanitary cleaning of gas emissions. Dust Collection Technical Handbook National Filter Media. Bag Filter working animation. If gas enters into the baghouse tangentially at the bottom of the casing, it gives the dust laden gas a circular motion which helps in removing the heavy and coarser particles that are 4. New Baghouse Filter Bags.

Fluctuation outside of these limits even for a small period, can damage the bags. The Reverse Air Bag House (RABH) is a custom-built filter, designed for cleaning gases with typically high flow rates and high temperatures. In the natural gas processing sector, bag filters are used in amines and glycols and for treating waste waters.

China Factory Price Baghouse Pulse Jet Dust Collecting Machine for Powder Making Plant, Find details about China Dust Collector, Pulse Jet Baghouse Dust Collector from Factory Price Baghouse Pulse Jet Dust Collecting Machine for Powder Making Plant - Botou Ever Lucky Environmental Protection Machinery Co., Ltd.

Sitemap 25

FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. in / sq.

FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. in / sq.  Efficiency. Product Categories. Working Design Considerations And Maintenance Of Bag Type. High (typically >99.5%) Highly dependent on application: Maintenance. Baghouse Filter - an overview | ScienceDirect Topics. Using a Triboelectric Broken Bag Detector as Early Warning. The material from which the sleeve is made is selected depending on the conditions of its Bag filter is the most widely used air pollution prevention and control dust, but also the most efficient dust precipitator.

Efficiency. Product Categories. Working Design Considerations And Maintenance Of Bag Type. High (typically >99.5%) Highly dependent on application: Maintenance. Baghouse Filter - an overview | ScienceDirect Topics. Using a Triboelectric Broken Bag Detector as Early Warning. The material from which the sleeve is made is selected depending on the conditions of its Bag filter is the most widely used air pollution prevention and control dust, but also the most efficient dust precipitator.  The main privileges of bag filters are efficiency, profitability, reliability and, accordingly, durability. Filter for cleaning the compressed air is installed in dust collection systems and aspiration. The main element of the bag filter is the filtering sleeves, which require replacement and often wear out. Reverse air cleaning High Pressure, Low Volume Medium Pressure Low Pressure. To do that it must overcome the resistance to flow created by the filters and the ductwork. The principle of baghouse dust collectors operation. Product Categories. In principle, dust may be collected on the inside or outside surface, with airflow from inside out or outside in, respectively. Filter bags, for gas filtration, are mainly used in large numbers in baghouses (fabric filters) for the filtration of solidgas suspensions with a reasonably high solids content (referred to as the dust load). Baghouse Filter June 01, 2022 Baghouse Dust Collector for Sale. System equipment (1) LCMD-type off-line deindustrialization and low pressure pulse bag dust collector frame structure and body boxes - structural frame is used to support the body of a dust collector, ash bunker and ash transport equipment, etc. They work on the principle of vacuum cleaners (Nicol, 2013) the flue gas passes through a filter, which rejects particles that are too large to pass through. 22.3.3 Fabric filters. FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. Bag Filter Working Principle. The working mechanism of the bag filter is that after the dust-laden flue gas enters the dust collector through the duct through the wind force of the induced draft fan, it passes through the first-level baffle (gravity sedimentation), the large specific gravity dust is intercepted and then settles into the ash hopper.

The main privileges of bag filters are efficiency, profitability, reliability and, accordingly, durability. Filter for cleaning the compressed air is installed in dust collection systems and aspiration. The main element of the bag filter is the filtering sleeves, which require replacement and often wear out. Reverse air cleaning High Pressure, Low Volume Medium Pressure Low Pressure. To do that it must overcome the resistance to flow created by the filters and the ductwork. The principle of baghouse dust collectors operation. Product Categories. In principle, dust may be collected on the inside or outside surface, with airflow from inside out or outside in, respectively. Filter bags, for gas filtration, are mainly used in large numbers in baghouses (fabric filters) for the filtration of solidgas suspensions with a reasonably high solids content (referred to as the dust load). Baghouse Filter June 01, 2022 Baghouse Dust Collector for Sale. System equipment (1) LCMD-type off-line deindustrialization and low pressure pulse bag dust collector frame structure and body boxes - structural frame is used to support the body of a dust collector, ash bunker and ash transport equipment, etc. They work on the principle of vacuum cleaners (Nicol, 2013) the flue gas passes through a filter, which rejects particles that are too large to pass through. 22.3.3 Fabric filters. FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. Bag Filter Working Principle. The working mechanism of the bag filter is that after the dust-laden flue gas enters the dust collector through the duct through the wind force of the induced draft fan, it passes through the first-level baffle (gravity sedimentation), the large specific gravity dust is intercepted and then settles into the ash hopper.  Fly ash is collected by the bag/filter itself, or by the accumulated Bag filter working principle: Bag filter is typically used in applications requiring gross particulate removal. 144 sq. The bag textile cloth made of felt or non Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. Filter for cleaning the compressed air is installed in dust collection systems and aspiration. National Filter Media has been around since 1906 and grown to one of the largest filter media companies in the world. Working Principle Of Vertical Raw Mill They work on the principle of vacuum cleaners (Nicol, 2013); the flue gas passes through a filter, which rejects particles that are too large to pass through. Conversely, static pressure or static resistance is a measurement of resistance generated by the ductwork and the filters in baghouse. The design and principle of operation of the baghouse filter allow you to take advantage of a number of functional and technological advantages: 1.Ease of installation and operation of the air purification system; 2.The possibility of continuous operation as part of the ventilation system; 3.Easy maintenance and minimal maintenance costs;

Fly ash is collected by the bag/filter itself, or by the accumulated Bag filter working principle: Bag filter is typically used in applications requiring gross particulate removal. 144 sq. The bag textile cloth made of felt or non Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. Filter for cleaning the compressed air is installed in dust collection systems and aspiration. National Filter Media has been around since 1906 and grown to one of the largest filter media companies in the world. Working Principle Of Vertical Raw Mill They work on the principle of vacuum cleaners (Nicol, 2013); the flue gas passes through a filter, which rejects particles that are too large to pass through. Conversely, static pressure or static resistance is a measurement of resistance generated by the ductwork and the filters in baghouse. The design and principle of operation of the baghouse filter allow you to take advantage of a number of functional and technological advantages: 1.Ease of installation and operation of the air purification system; 2.The possibility of continuous operation as part of the ventilation system; 3.Easy maintenance and minimal maintenance costs;  Enter (Bag Diameter Length of Cages # of Bags). ft. Then Click on Calculate To Find the Cloth Area Fans on the outside of the housing blow the dirty or polluted air through the filters, capturing the suspended particulate matter and solids on the bags and pushing clean air through the outlet. While filtering, a baghouse bag allows the formation of a layer of particulate matter on its surface, called a dust cake. Bag Filter Working Principle. Baghouse Basics operation and maintenance Presented by: Brent McIntosh Baghouse Applications Dust Control Found at end of dust control system to filter air Bin/Silo Venting

Enter (Bag Diameter Length of Cages # of Bags). ft. Then Click on Calculate To Find the Cloth Area Fans on the outside of the housing blow the dirty or polluted air through the filters, capturing the suspended particulate matter and solids on the bags and pushing clean air through the outlet. While filtering, a baghouse bag allows the formation of a layer of particulate matter on its surface, called a dust cake. Bag Filter Working Principle. Baghouse Basics operation and maintenance Presented by: Brent McIntosh Baghouse Applications Dust Control Found at end of dust control system to filter air Bin/Silo Venting  Moderate (if correctly sized/designed) exiting baghouse to atmosphere. This type of dust remover can be widely used in glass installation, warehouse roof, cooked cooling machine and mill dust collection system in cement plants. Fabric Filter Baghouse Consulting And Design Case Studies. The filter bag generates rapid expansion and impact vibration from the mouth of the bag to the bottom, resulting in a strong cleaning action, shaking the filter Dust on the bag. Bag Filter working animation. Keeping the air clean of dust is crucial for environmental and human protection but is also very important for proper production.

Moderate (if correctly sized/designed) exiting baghouse to atmosphere. This type of dust remover can be widely used in glass installation, warehouse roof, cooked cooling machine and mill dust collection system in cement plants. Fabric Filter Baghouse Consulting And Design Case Studies. The filter bag generates rapid expansion and impact vibration from the mouth of the bag to the bottom, resulting in a strong cleaning action, shaking the filter Dust on the bag. Bag Filter working animation. Keeping the air clean of dust is crucial for environmental and human protection but is also very important for proper production.  100 gm Clean gas conc.

100 gm Clean gas conc.  The first series of bags that the air passes through works to accumulate the dust particulate.

The first series of bags that the air passes through works to accumulate the dust particulate.  Lecture 4 Design Of Fabric Filter NPTEL. The baghouse dust collector for ventilation and air treatment is one of the most effective air treatment devices capable of catching air pollutants and used for cleaning gases and gas mixtures. ; The box body includes the upper body of the box, the The particles are captured within the filter and removed before clean gas is emitted. Main Parts of Bag House Filter . Fabric filter. Baghouse filter vs Cyclone. The air charged of dust is suctioned in the hopper or directly in the filter body by means of an aerodynamic inlet duct designed to obtain a uniform info@senotay.com +86-15831871808. Robinsons Filter Solutions sells a wide range of aftermarket baghouse filter bags, dust filter socks and dust collector bags to fit OEM baghouse systems including Nordson, Donaldson Torit, Murphy, MacDonald Steel and Canoblast, among many others. The working principle of an ESP consists of the application between a discharge electrode and a collection electrode (usually known as plates) of a sufficiently high electric voltage difference Baghouse filters require regular replacement, which can make them expensive to operate.

Lecture 4 Design Of Fabric Filter NPTEL. The baghouse dust collector for ventilation and air treatment is one of the most effective air treatment devices capable of catching air pollutants and used for cleaning gases and gas mixtures. ; The box body includes the upper body of the box, the The particles are captured within the filter and removed before clean gas is emitted. Main Parts of Bag House Filter . Fabric filter. Baghouse filter vs Cyclone. The air charged of dust is suctioned in the hopper or directly in the filter body by means of an aerodynamic inlet duct designed to obtain a uniform info@senotay.com +86-15831871808. Robinsons Filter Solutions sells a wide range of aftermarket baghouse filter bags, dust filter socks and dust collector bags to fit OEM baghouse systems including Nordson, Donaldson Torit, Murphy, MacDonald Steel and Canoblast, among many others. The working principle of an ESP consists of the application between a discharge electrode and a collection electrode (usually known as plates) of a sufficiently high electric voltage difference Baghouse filters require regular replacement, which can make them expensive to operate.  The longer a leak persists the worse it becomes, often quickly causing a plant to exceed its maximum PM 2.5 emissions limits set out in its air permit. Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Shaker Baghouse. The baghouse filter may also be equipped with a mechanism that can remove dust from the air inside it. 1 electromagnetic pulse valve. Product Categories. Reverse air baghouse optimization with GORE LOW DRAG Filter Bags Astec Inc. - Manufacturers of continuous and batch-process The working principle of Senotay baghouse filter is a filtering process and a cleaning process. baghouse and then through the filters and out to exhaust. due to the lower air-to-cloth ratio achieved with the reverse air baghouse working principle. News; Service; Resource; Contact Us Fabric Filter Baghouse Consulting And Design Case Studies.

The longer a leak persists the worse it becomes, often quickly causing a plant to exceed its maximum PM 2.5 emissions limits set out in its air permit. Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Shaker Baghouse. The baghouse filter may also be equipped with a mechanism that can remove dust from the air inside it. 1 electromagnetic pulse valve. Product Categories. Reverse air baghouse optimization with GORE LOW DRAG Filter Bags Astec Inc. - Manufacturers of continuous and batch-process The working principle of Senotay baghouse filter is a filtering process and a cleaning process. baghouse and then through the filters and out to exhaust. due to the lower air-to-cloth ratio achieved with the reverse air baghouse working principle. News; Service; Resource; Contact Us Fabric Filter Baghouse Consulting And Design Case Studies.  Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant , Find Complete Details about Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant,Baghouse Type Bag Filter Dust Collector,Industrial Baghouse Dust Collector,Baghouse Dust Collector from Dust Collector Supplier or Manufacturer-Botou Ever Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant , Find Complete Details about Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant,Baghouse Type Bag Filter Dust Collector,Industrial Baghouse Dust Collector,Baghouse Dust Collector from Dust Collector Supplier or Manufacturer-Botou Ever

Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant , Find Complete Details about Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant,Baghouse Type Bag Filter Dust Collector,Industrial Baghouse Dust Collector,Baghouse Dust Collector from Dust Collector Supplier or Manufacturer-Botou Ever Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant , Find Complete Details about Factory Price Baghouse Pulse Jet Dust Collecting Machine For Powder Making Plant,Baghouse Type Bag Filter Dust Collector,Industrial Baghouse Dust Collector,Baghouse Dust Collector from Dust Collector Supplier or Manufacturer-Botou Ever  The airstream enters below the bag filters and is pulled up through the filtering system. In pharmaceutical production, very potent drugs such as hormones, vitamins, antibiotics, etc generate a lot of dust during processing which may be life-threatening to the operators. Dust every small particle such us cement, ash, sawdust or even sugar, flour etc. In reverse-air baghouses, the bags are fastened onto a cell plate at the bottom of the baghouse and suspended from an adjustable hanger frame at the top. Baghouse. Pulse-jet baghouses are the most common type of nonwoven filter. It is controlled by the electric signals from the pulse -jet control device. suspended in the air. Produced water or brines from shale gas Bag Filter Pulse Jet Valve Application: Pulse Jet Valve, also called diaphragm valve acts as a switch for compressed air in the dust clean blowing system for pulse bag filters. July 30, 2019. Baghouse works principle. A baghouse also known as a baghouse filter bag filter or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. New Baghouse Filter Bags. This type of reverse air baghouse generates a lower pressure than the compressed air pulses of a pulse jet.

The airstream enters below the bag filters and is pulled up through the filtering system. In pharmaceutical production, very potent drugs such as hormones, vitamins, antibiotics, etc generate a lot of dust during processing which may be life-threatening to the operators. Dust every small particle such us cement, ash, sawdust or even sugar, flour etc. In reverse-air baghouses, the bags are fastened onto a cell plate at the bottom of the baghouse and suspended from an adjustable hanger frame at the top. Baghouse. Pulse-jet baghouses are the most common type of nonwoven filter. It is controlled by the electric signals from the pulse -jet control device. suspended in the air. Produced water or brines from shale gas Bag Filter Pulse Jet Valve Application: Pulse Jet Valve, also called diaphragm valve acts as a switch for compressed air in the dust clean blowing system for pulse bag filters. July 30, 2019. Baghouse works principle. A baghouse also known as a baghouse filter bag filter or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. New Baghouse Filter Bags. This type of reverse air baghouse generates a lower pressure than the compressed air pulses of a pulse jet.  Dust-filled air is pushed via hoppers through the fabric bags during the process.

Dust-filled air is pushed via hoppers through the fabric bags during the process.

Baghouse Fabric Filter Dust Collector Foundry Use Dust Removal Equipment . Metallurgy Pulse Baghouse Fabric Filter 0.4Mpa Dust Collector Equipment . Whether you are using pulse-jet baghouse technology or reverse air filter bags, you need to be confident that your process meets the regulations around particulate matter compliance testing. As with the reverse air filters, dust, dirt, particulates, and contaminants collect on the outside of the bag filter and are removed by bursts of compressed air that moves along the length of the bag. Baghouse filter working principle pdf 4. Most leaking baghouse filters begin as small holes or rips that overtime become worse and worse. 10 mgm n.c. dry Leading process filter technologies by Intensiv-Filter Filter area 13.700 m 4 Enhanced Energy Efficiency Solutions for Bag Filters 1 Introduction. FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. The working principle of Senotay baghouse filter is a filtering process and a cleaning process. With so many different types of baghouse filter fabrics and treatments options to choose from, its important to know which is the best fit for your specific application. Steady air circulation continuously pulls air through the filter bags. Working principle of baghouse dust collector 2020-07-03 Industrial Dust Collectors Industrial vacuum cleaners are the industrial dust collectors used in industrial applications for the collection, absorption, production, operation, and transportation of waste materials such as waste media particles, dust, smoke, oil and water. Posted on 2015-10-01 by shengjie.

Baghouse Fabric Filter Dust Collector Foundry Use Dust Removal Equipment . Metallurgy Pulse Baghouse Fabric Filter 0.4Mpa Dust Collector Equipment . Whether you are using pulse-jet baghouse technology or reverse air filter bags, you need to be confident that your process meets the regulations around particulate matter compliance testing. As with the reverse air filters, dust, dirt, particulates, and contaminants collect on the outside of the bag filter and are removed by bursts of compressed air that moves along the length of the bag. Baghouse filter working principle pdf 4. Most leaking baghouse filters begin as small holes or rips that overtime become worse and worse. 10 mgm n.c. dry Leading process filter technologies by Intensiv-Filter Filter area 13.700 m 4 Enhanced Energy Efficiency Solutions for Bag Filters 1 Introduction. FFs, or baghouse filters, operate on relatively simple processes compared with ESP and have better particulate removal efficiency. The working principle of Senotay baghouse filter is a filtering process and a cleaning process. With so many different types of baghouse filter fabrics and treatments options to choose from, its important to know which is the best fit for your specific application. Steady air circulation continuously pulls air through the filter bags. Working principle of baghouse dust collector 2020-07-03 Industrial Dust Collectors Industrial vacuum cleaners are the industrial dust collectors used in industrial applications for the collection, absorption, production, operation, and transportation of waste materials such as waste media particles, dust, smoke, oil and water. Posted on 2015-10-01 by shengjie.  Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Lecture 4 Design Of Fabric Filter NPTEL. Figure 5.33 shows the two possible modes of operation for baghouse filters. Inside-out filtration implies that the gas passes through the filter from the inside. This blows up the bag filters to their maximum volume and produces the cake on the inside of the bag. Outside-in operation involves that the gas

Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Lecture 4 Design Of Fabric Filter NPTEL. Figure 5.33 shows the two possible modes of operation for baghouse filters. Inside-out filtration implies that the gas passes through the filter from the inside. This blows up the bag filters to their maximum volume and produces the cake on the inside of the bag. Outside-in operation involves that the gas  The baghouse or fabric filter can be safely operated only within the temperature range specified by the manufacturer. Air filtration technology is the bag filter working principle. baghouse, cleaning can be carried out while the baghouse is on-line (filtering) or is off-line (in isolation). Choosing the correct baghouse filter will maximize performance, increase filter life, reduce system downtime and save you money. Bag Cleaning Systems.

The baghouse or fabric filter can be safely operated only within the temperature range specified by the manufacturer. Air filtration technology is the bag filter working principle. baghouse, cleaning can be carried out while the baghouse is on-line (filtering) or is off-line (in isolation). Choosing the correct baghouse filter will maximize performance, increase filter life, reduce system downtime and save you money. Bag Cleaning Systems.  This paper mainly focuses on the analysis of working principles, computer simulation of the operation and design consideration of the inverter for grid-connected applications.. Baghouse Filter Basics.

This paper mainly focuses on the analysis of working principles, computer simulation of the operation and design consideration of the inverter for grid-connected applications.. Baghouse Filter Basics.

Baghouse filters are the most common way to contain dust from industrial emissions. Reverse air baghouse optimization with GORE LOW DRAG Filter Bags Astec Inc. - Manufacturers of continuous and batch-process. When the dust-containing gas passes through the filter media, the dust is stopped on its surface and the clean air is discharged through the gaps of the filter media. The working mechanism of the bag filter is that after the dust-laden flue gas enters the dust collector through the duct through the wind force of the induced draft fan, it passes through the first-level baffle (gravity sedimentation), the large specific gravity dust is intercepted and then settles into the ash hopper.

Baghouse filters are the most common way to contain dust from industrial emissions. Reverse air baghouse optimization with GORE LOW DRAG Filter Bags Astec Inc. - Manufacturers of continuous and batch-process. When the dust-containing gas passes through the filter media, the dust is stopped on its surface and the clean air is discharged through the gaps of the filter media. The working mechanism of the bag filter is that after the dust-laden flue gas enters the dust collector through the duct through the wind force of the induced draft fan, it passes through the first-level baffle (gravity sedimentation), the large specific gravity dust is intercepted and then settles into the ash hopper.  Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Filter bags are made of polypropylene or polyester Bag Filters Cyclone cum Bag Filters Air Pollution Control Re: Bag filter design and working principle Dear Sir, would be please send me the excel sheet or any soft copy for designing procedure of bag filter My E-mail ID:- [email protected] or [email protected] I ,

Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. Filter bags are made of polypropylene or polyester Bag Filters Cyclone cum Bag Filters Air Pollution Control Re: Bag filter design and working principle Dear Sir, would be please send me the excel sheet or any soft copy for designing procedure of bag filter My E-mail ID:- [email protected] or [email protected] I ,

Baghouse Fabric Filter Dust Collector Foundry Use Dust Removal Equipment . Baghouse dust collectors filter dust particles from the ambient airstream using long fabric bags (or tubes). The valve induces air several times the amount of air injected into the filter bag through the nozzle on the blowing pipe to form an air wave.

Baghouse Fabric Filter Dust Collector Foundry Use Dust Removal Equipment . Baghouse dust collectors filter dust particles from the ambient airstream using long fabric bags (or tubes). The valve induces air several times the amount of air injected into the filter bag through the nozzle on the blowing pipe to form an air wave.  Raw gas conc.

Raw gas conc.  Baghouse.com Control air pollution with baghouse filter bags. Robinsons Filter Solutions sells a wide range of aftermarket baghouse filter bags, dust filter socks and dust collector bags to fit OEM baghouse systems including Nordson, Donaldson Torit, Murphy, MacDonald Steel and Canoblast, among many others. As well, we can have custom baghouse filter bags manufactured to meet your specific The working principle is adopting solenoid valve to control the cylinder and the top door. The main element of the bag filter is the filtering sleeves, which require replacement and often wear out. Baghouse dust collectors offer a comparatively inexpensive method of collecting solid particles from an air or gas stream. Baghouse Filter - an overview | ScienceDirect Topics. Bag filter working principle: Bag filter is typically used in applications requiring gross particulate removal. Dust Collection Technical Handbook National Filter Media. System equipment (1) LCMD-type off-line deindustrialization and low pressure pulse bag dust collector frame structure and body boxes - structural frame is used to support the body of a dust collector, ash bunker and ash transport equipment, etc. Filter bags are made of polypropylene or polyester Bag Filters Cyclone cum Bag Filters Air Pollution Control The main privileges of bag filters are efficiency, profitability, reliability and, accordingly, durability. 2 Depending on the type of installation, the baghouse dust collectors can also be installed horizontally so that the maximum amount of air passes through them. The working principle of Senotay baghouse filter is a filtering process and a cleaning process. Thomas H. Wines, Saeid Mokhatab, in Contamination Control in the Natural Gas Industry, 2022 4.6.6 Liquid bag filters. Pulse-jet filter bags can be manufactured from most available felt or woven filter medias. The polluted air will move through a series of filters throughout a dust collector in the baghouse system. For cleaning, a fan rotates over the bags, blowing reverse air into them to remove dust.

Baghouse.com Control air pollution with baghouse filter bags. Robinsons Filter Solutions sells a wide range of aftermarket baghouse filter bags, dust filter socks and dust collector bags to fit OEM baghouse systems including Nordson, Donaldson Torit, Murphy, MacDonald Steel and Canoblast, among many others. As well, we can have custom baghouse filter bags manufactured to meet your specific The working principle is adopting solenoid valve to control the cylinder and the top door. The main element of the bag filter is the filtering sleeves, which require replacement and often wear out. Baghouse dust collectors offer a comparatively inexpensive method of collecting solid particles from an air or gas stream. Baghouse Filter - an overview | ScienceDirect Topics. Bag filter working principle: Bag filter is typically used in applications requiring gross particulate removal. Dust Collection Technical Handbook National Filter Media. System equipment (1) LCMD-type off-line deindustrialization and low pressure pulse bag dust collector frame structure and body boxes - structural frame is used to support the body of a dust collector, ash bunker and ash transport equipment, etc. Filter bags are made of polypropylene or polyester Bag Filters Cyclone cum Bag Filters Air Pollution Control The main privileges of bag filters are efficiency, profitability, reliability and, accordingly, durability. 2 Depending on the type of installation, the baghouse dust collectors can also be installed horizontally so that the maximum amount of air passes through them. The working principle of Senotay baghouse filter is a filtering process and a cleaning process. Thomas H. Wines, Saeid Mokhatab, in Contamination Control in the Natural Gas Industry, 2022 4.6.6 Liquid bag filters. Pulse-jet filter bags can be manufactured from most available felt or woven filter medias. The polluted air will move through a series of filters throughout a dust collector in the baghouse system. For cleaning, a fan rotates over the bags, blowing reverse air into them to remove dust.  It is suitable for trapping a small, dry, non-fibrous dust. Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. A Baghouse Filter is a high-efficiency filter.

It is suitable for trapping a small, dry, non-fibrous dust. Figure 5.33 Baghouse filter systems based on inside out (left) and outside-in (right) filtration (picture from Klingspor and Vernon, 1988) 5.8. A Baghouse Filter is a high-efficiency filter.  Baghouse is a dry dust filter device. The baghouse or fabric filter can be safely operated only within the temperature range specified by the manufacturer. Baghouse filters and cartridges filters work thanks to the filtration principle by micro-perforated textile, made in the form of cylindrical bags or pleated cartridges that are fixed to the filter structure and supported by metal cages. We know dust collection. A shaker baghouse, as the name suggests, mechanically disposes of collected dust by shaking it out of the bags into a collection hopper at the bottom of the baghouse. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. Venturi is short for venture tube, the working principle of venturi is that when the air blows through the barrier, the pressure near the port above the leeward side of the barrier is relatively low, thereby producing adsorption and causing air flow. Bag Filter Pulse Jet Valve Application: Pulse Jet Valve, also called diaphragm valve acts as a switch for compressed air in the dust clean blowing system for pulse bag filters. They work on the principle of vacuum cleaners (Nicol, 2013); the flue gas passes through a filter, which rejects particles that are too large to pass through. Pulse-jet filter bags are July 30, 2019. Fluctuation outside of these limits even for a small period, can damage the bags. ; The box body includes the upper body of the box, the Cyclone. Working Design Considerations And Maintenance Of Bag Type. How It Works. Bag Filter - Principle, Construction, Working, and More The bag filter is a mechanical device used in the quality of air in pharmaceutical production and other allied areas. Process filter kiln and rawmeal mill dedusting - France Volume flow 1.000.000 m h n.c.. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. 22.3.3 Fabric filters. Nowadays, the popularity of cartridge dust collectors continues The baghouse dust collector for ventilation and air treatment is one of the most effective air treatment devices capable of catching air pollutants and used for cleaning gases and gas mixtures. Baghouse filter working principle pdf 4. The dirty gas stream enters the baghouse either via an inlet air plenum or directly into the hopper. Air treatment devices are widely used in industry for accurate cleaning of ventilation air from dust particles, as well as for industrial and sanitary cleaning of gas emissions. Dust Collection Technical Handbook National Filter Media. Bag Filter working animation. If gas enters into the baghouse tangentially at the bottom of the casing, it gives the dust laden gas a circular motion which helps in removing the heavy and coarser particles that are 4. New Baghouse Filter Bags.

Baghouse is a dry dust filter device. The baghouse or fabric filter can be safely operated only within the temperature range specified by the manufacturer. Baghouse filters and cartridges filters work thanks to the filtration principle by micro-perforated textile, made in the form of cylindrical bags or pleated cartridges that are fixed to the filter structure and supported by metal cages. We know dust collection. A shaker baghouse, as the name suggests, mechanically disposes of collected dust by shaking it out of the bags into a collection hopper at the bottom of the baghouse. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. Venturi is short for venture tube, the working principle of venturi is that when the air blows through the barrier, the pressure near the port above the leeward side of the barrier is relatively low, thereby producing adsorption and causing air flow. Bag Filter Pulse Jet Valve Application: Pulse Jet Valve, also called diaphragm valve acts as a switch for compressed air in the dust clean blowing system for pulse bag filters. They work on the principle of vacuum cleaners (Nicol, 2013); the flue gas passes through a filter, which rejects particles that are too large to pass through. Pulse-jet filter bags are July 30, 2019. Fluctuation outside of these limits even for a small period, can damage the bags. ; The box body includes the upper body of the box, the Cyclone. Working Design Considerations And Maintenance Of Bag Type. How It Works. Bag Filter - Principle, Construction, Working, and More The bag filter is a mechanical device used in the quality of air in pharmaceutical production and other allied areas. Process filter kiln and rawmeal mill dedusting - France Volume flow 1.000.000 m h n.c.. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in the previous section. 22.3.3 Fabric filters. Nowadays, the popularity of cartridge dust collectors continues The baghouse dust collector for ventilation and air treatment is one of the most effective air treatment devices capable of catching air pollutants and used for cleaning gases and gas mixtures. Baghouse filter working principle pdf 4. The dirty gas stream enters the baghouse either via an inlet air plenum or directly into the hopper. Air treatment devices are widely used in industry for accurate cleaning of ventilation air from dust particles, as well as for industrial and sanitary cleaning of gas emissions. Dust Collection Technical Handbook National Filter Media. Bag Filter working animation. If gas enters into the baghouse tangentially at the bottom of the casing, it gives the dust laden gas a circular motion which helps in removing the heavy and coarser particles that are 4. New Baghouse Filter Bags.  Fluctuation outside of these limits even for a small period, can damage the bags. The Reverse Air Bag House (RABH) is a custom-built filter, designed for cleaning gases with typically high flow rates and high temperatures. In the natural gas processing sector, bag filters are used in amines and glycols and for treating waste waters.

Fluctuation outside of these limits even for a small period, can damage the bags. The Reverse Air Bag House (RABH) is a custom-built filter, designed for cleaning gases with typically high flow rates and high temperatures. In the natural gas processing sector, bag filters are used in amines and glycols and for treating waste waters.  China Factory Price Baghouse Pulse Jet Dust Collecting Machine for Powder Making Plant, Find details about China Dust Collector, Pulse Jet Baghouse Dust Collector from Factory Price Baghouse Pulse Jet Dust Collecting Machine for Powder Making Plant - Botou Ever Lucky Environmental Protection Machinery Co., Ltd.

China Factory Price Baghouse Pulse Jet Dust Collecting Machine for Powder Making Plant, Find details about China Dust Collector, Pulse Jet Baghouse Dust Collector from Factory Price Baghouse Pulse Jet Dust Collecting Machine for Powder Making Plant - Botou Ever Lucky Environmental Protection Machinery Co., Ltd.