Napite nm zprvu na. Perforated, perfumed, embossed, and colored ones are all common features. A troufme si ct, e vme, jak to v dnenm svt financ a developmentu funguje.NIDO jsme zaloili v roce 2016, o rok pozdji jsme zaali s rekonstrukcemi nemovitost a spolenmi developerskmi projekty. This type of paper has usually a basis weight of 20 to 24 g/m2.

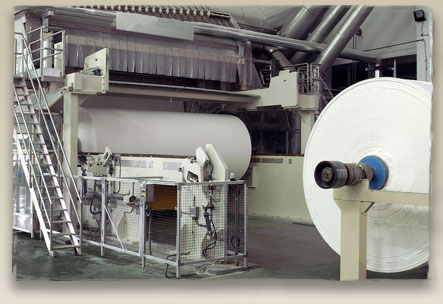

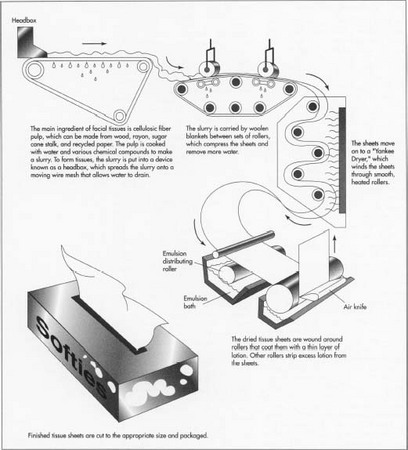

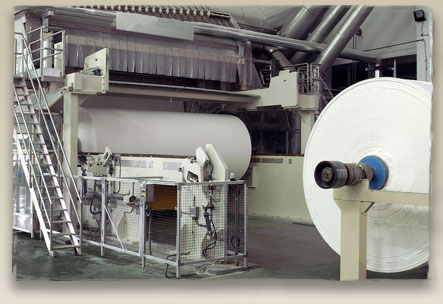

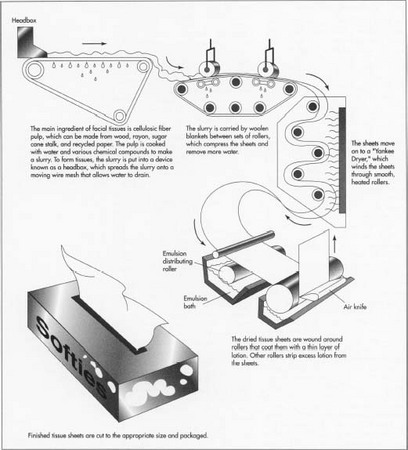

The industry contributes less than 0.5% of all solid waste and around 2% of municipal solid waste (MSW) compared with paper and board, garden waste and food waste which each comprise between 18 and 20 percent of MSW.[28]. Toilet paper is a kind of tissue paper that is used in every household for cleanliness or to maintain hygiene and is similar to facial tissue. to keep shape intact or, for inserting in garments etc. The main materials used to prodcue toilet paper include: Photo Credit: Juan Arredondo for The New York Times. 9. In North America, people are consuming around three times as much tissue as in Europe. So there are two types of toilet paper manufacturing. Andrex was the first paper company to make moist toilet paper, sometimes known as 'Wet Wipes,' in the United Kingdom in the 1990s. [11], Tissue paper, in the form of standard single-ply toilet paper, is commonly used in road repair to protect crack sealants. The tissue can then be made into either flat surfaces or wound around a cardboard tube to create a cylindrical rolls.

[20] Dal nekategorizovan soubory cookie jsou ty, kter jsou analyzovny a dosud nebyly zaazeny do dn kategorie. Toilet paper is then pulverized and reformed into very thin and soft paper. Toilet paper is made from recyclable paper which has a lower environmental impact than that made from virgin paper. Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. After that, the tissue paper is often pressed, embossed, scented, perforated, and/or colored. The logs are carefully debarked with machine to leave as much wood as possible. The moisture in the wood is evaporated and the mass is reduces to cellulose fibers, lignin and other substances. You can tell a Paper Profile meets the Type III requirements when the verifiers logo is included on the document.[32]. To leave as much wood as possible, the logs are meticulously debarked with a machine. Kidadl is supported by you, the reader. Preparing trees (a combination of softwood and hardwood trees). Investin skupina specializujc se primrn na developersk projekty.

Funkn soubory cookie pomhaj provdt urit funkce, jako je sdlen obsahu webovch strnek na platformch socilnch mdi, shromaovn zptn vazby a dal funkce tetch stran. To give the toilet paper a pure white color, companies use chlorine. Be the first to know about new B2B SaaS Marketing insights to build or refine your marketing function with the tools and knowledge of todays industry. Stirring together these fine retted flakes in a mixer tank with a large quantity of water and other chemicals generates. Hardwood trees with shorter strands, such as maple and oak, produce soft paper. Paper is sometimes created from recycled materials, but materials like virgin tree pulp is also used. [9][11] The authors of a study for Studio Sound magazine suggested that had the speakers' grilles been used in studios, they would have had the same effect on the treble output as the improvised tissue paper filter. Mte tak monost odhlsit se z tchto soubor cookie. 10. When Scott paper, one of the paper companies, began producing toilet paper on rolls in 1890, it became popular. As a result, the industry has often been scrutinized for deforestation. A life-cycle assessment study indicated that neither fibre type can be considered environmentally preferable. In North and South America, companies cut down many trees, causing environmental issues. Improve energy efficiency in tissue manufacturing; Examine opportunities for changing to alternative, non fossil based sources, of, Deliver products that maximise functionality and optimize consumption; and. 2. During the early time, Zhejiang generated millions of sheets of toilet paper per year. The tissue production process upis basedon the manufacturing of raw material such as virgin pulp and waste paper. The history of toilet paper dates back to the Tang and the Ming dynasty. Whitening with oxygen, ozone, or sodium gas is a common practice in the recycling industry. Lignin, the glue that holds fibers together, must be removed from the pulp or the papers would yellow over time. 4. Softwood and hardwood trees are used to make virgin-fiber toilet paper. Unlike dry toilet paper rolls, moist toilet paper swiftly decomposes in the environment. To make paper stock, the company combines pulp with a large amount of water (99.5% final moisture and 0.5% fiber). S fortelem. 3. Companies will use various forms of solutions to do this, but it all needs to be washed and deinked prior to being pulped. In 2015, the global market for tissue paper is growing at per annum rates between 89% (China, currently 40% of global market) and 23% (Europe). [17], In Europe, the industry is represented by the European Tissue Symposium (ETS), a trade association. The properties are controlled by pulp quality, crping and additives (both in base paper and as coating). Paper Converting Machinery Selection and Best Buying Guide, 4 Different Types of Paper Stocks for Printing, Importance of Adsorption Chillers in Various Industries. In 2002, it noted that "a little over 60% of the pulp and paper produced in Europe comes from mills certified under one of the internationally recognised eco-management schemes". The wood chips are separated into batches. [19], Tissue paper production and consumption is predicted to continue to grow because of factors like urbanization, increasing disposable incomes and consumer spending. The prepared pulp is then poured over fast moving belts made from highly porous materials that are driven over huge drums heated by steam. Toilet paper is largely made of chemical pulp, but it all starts with paper. Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. Pouvme tak soubory cookie tetch stran, kter nm pomhaj analyzovat a porozumt tomu, jak tento web pouvte. However, most toilet paper today is made from a chemical pulp. Toilet paper was first used by a Chinese emperor in medieval China, who utilized sheets of paper. Facial tissue (paper handkerchiefs) refers to a class of soft, absorbent, disposable paper that is suitable for use on the face. Analytick soubory cookie se pouvaj k pochopen toho, jak nvtvnci interaguj s webem. European Disposables and Nonwoven Association, Toilet paper Environmental considerations, Confederation of European Paper Industries, "Yamaha's NS-10: The Most Important Speaker You've Never Heard Of", 1977 Yamaha NS-10M Speakers|Mix Inducts the Yamaha NS10M Speakers into the TECnology Hall of Fame, "The Yamaha NS10M: Twenty Years a Reference Monitor. Garantujeme zhodnocen pinejmenm 7,2 procenta.

All the pulp come from certificated forests. Manufacturers created it from trees, that is, from small pieces of virgin paper fiber which is made from a mix of softwood and hardwood trees. Less than 1% of all commercial wood production ends up as wood pulp in absorbent hygiene products. while packing/folding to keep them wrinkle free and safe.

Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. [7], In the late 1970s and early 1980s, a sound recording engineer named Bob Clearmountain was said to have hung tissue paper over the tweeter of his pair of Yamaha NS-10 speakers to tame the over-bright treble coming from it. The biggest difference between toilet papers is the distinction between virgin paper products (formed from chipped wood) and those made from recycled paper. The tissue is taken and its plies are split and passed through an embossing roller. The lignin and heating chemicals are then removed from the pulp. For information please visit the page about tissue production. It is bleached and scented at the conclusion of the procedure. 8. Creping is done by the Yankee's doctor blade that is scraping the dry paper off the cylinder surface. The trees are broken down into usable fiber by water and chemicals. By continuing to browse this website you accept the use of cookies. This page was last edited on 27 May 2022, at 10:26. Zajmaj vs investice do developerskch projekt? The paper is then fed into machines that perforate it into squares and cut it into long strips. It is a type of thin, translucent paper generally in the range of grammages between 17 and 40 GSM, that can be rough or, shining, hard or soft, depending upon the nature of use. Malm i vtm investorm nabzme monost zajmav zhodnotit penze. In this study both new fibre and recovered fibre offer environmental benefits and shortcomings. Finally, the paper logs are cut into rolls and wrapped packages. Adjust the draw speed of the roll can let you get a thicker or thinner tissue as per your goal. [4], The importance of the paper tissue on minimising the spread of an infection has been highlighted in light of fears over a swine flu epidemic. Pressure on use of tissue papers has grown in the wake of improved hygiene concerns in response to the coronavirus pandemic. pedevm do rezidennch developerskch projekt. ", "Examining the Yamaha NS-10M 'Tissue Paper Phenomenon' An Analysis of the Industry-Wide Practice of Using a Tissue-Paper Layer to Reduce High-Frequency Output", "Littleton TP's its own streets as a way to fill its cracks single-ply only", "City crews hitting the streets with single-ply toilet paper", "Is tissue becoming a safe haven for the global pulp and paper industry? Toilet paper comes in a variety of thicknesses and roll sizes.

The paper roll is made up of long threads that give it strength. Recyclable paper pulp (fibers) and water, along with chemicals such as sulfurate assist the paper degradation and starches which make it tough and durable when moist are used to make white toilet paper. For the first time, in the sixth century BC, paper was used in China for hygiene or washing in spite of its invention being in the second century BC. By joining Kidadl you agree to Kidadls. Nezbytn soubory cookie jsou naprosto nezbytn pro sprvn fungovn webu. Next step is choosing a solution to remove ink. These papers contain high amounts of NBSK and CTMP. Type I: ISO 14024

Other materials for final product of toilet paper include water, chemicals and bleaches. Ve dvou etapch postavme devatenct dom v hodnot pes 120 milion korun. How Manufacturing Companies Can Use Apps to Reduce Paper Waste, Use of Industrial Conveyors in the Pulp and Paper Industry, Use of water treatment products in the paper industry, Avoiding Expensive Mistakes: Testing Your Tools for Automated Print Jobs, CNC Tooling for the Paper & Pulp Industry. By joining Kidadl you agree to Kidadls Terms of Use and Privacy Policy and consent to receiving marketing communications from Kidadl. [16], The European tissue market is worth approximately 10 billion Euros annually and is growing at a rate of around 3%. Forms of paper used in the production of tissue paper can include various forms of recylced paper, virgin tree pulp, as well as hemp plants. Today, more than 20 billion rolls of toilet tissue are used each year in Western Europe.[4]. It is created from virgin wood fibers or a mixture of recycled paper pulp and water, together with chemical sulfates mixed to help it break down fibers, starches mixed for wet strength, and chlorine to make it white.

The paper stock is sprayed onto screens of mesh that drain the water. Trees are logged and cut into chips, which are then are ground into fine flakes, which are then soaked and pulled-apart (retted). Manage the raw material sources to maintain legal, sustainable forestry practices by implementing processes such as.

Colored and white stock with staples are used. It shields the hands from damage while they are being processed. Eco-labelling entered mainstream environmental policy-making in the late seventies, first with national schemes such as the German Blue Angel programme, to be followed by the Nordic swan (1989). A v plnu mme celou adu dalch vc. Every day, 27,000 trees are cut down for toilet paper production around the world. The one that has European application is the EU Flower. The pulp is what paper is made from. This gives a bulky paper with high wet tensile strength and good water holding capacity. Cookie se pouv k uloen souhlasu uivatele s cookies v kategorii Jin". Sometimes known as EPDs (Environmental Product Declarations), these labels are based on an independent review of the life cycle of the product. Select the recovered paper depending on the end-product requirements and that also allows the most efficient recycling process. Total environmental impacts vary case by case, depending on for example the location of the tissue paper mill, availability of fibres close to the mill, energy options and waste utilization possibilities.

Paper towels are the second largest application for tissue paper in the consumer sector. Its specific primary energy consumption has decreased by 16% and the specific electricity consumption has decreased by 11%, due to measures such as improved process technology and investment in combined heat and power (CHP). Once consumed, most forest-based paper products start a new life as recycled material or biofuel[27], EDANA, the trade body for the non-woven absorbent hygiene products industry (which includes products such as household wipes for use in the home) has reported annually on the industry's environmental performance since 2005. However, more companies are presently using more recycled fibres in tissue paper. The chemicals used in the making are ozone, peroxide, oxygen, and sodium hydroxide or peroxide for the paper to be bleached. In the same year, 15,000 sheets of scented toilet paper with a special soft-fabric sheet backing were manufactured. It is actually a process of using both hardwood and softwood from "virgin" trees.

The plies are removed and held together with glue. Subscribe and take advantage of this platform. Toxins like dioxin and furans are produced when chlorine bleach is used. The heat of the Yankee makes the fabric dry almost instantly. The combination of hardwood to softwood is approximetly 30% softwood and 70% hardwood. So there are two kind of manufacturing process for the toilet paper. [18], In the U.S., the tissue industry is organized in the AF&PA.

Copyright 2018 Pulp and Paper Technology. Custom-printed wrapping tissue is becoming a popular trend for boutique retail businesses. To give the toilet paper it's pure white color companies use various methods to achieve this including ozone, peroxide, oxygen and/or sodium hydroxide. The industry relies heavily on biofuels (about 50% of its primary energy). 6.

[25][26], Meanwhile, the paper tissue industry, along with the rest of the paper manufacturing sector, has worked to minimise its impact on the environment. Tissue can be made from recycled paper pulp on a paper machine. Soubor cookie je nastaven na zklad souhlasu s cookie GDPR k zaznamenn souhlasu uivatele pro soubory cookie v kategorii Funkn. Obrat skupiny v roce 2020 doshnul 204 milion korun. Zhodnotme mal, vt i velk prostedky prostednictvm zajmavch projekt od rodinnch devostaveb po velk rezidenn a bytov domy. Batches of wood chips are separated. The wood's moisture evaporates, reducing the bulk to cellulose fibers, lignin, and other components. [24] According to the Worldwatch Institute, the world per capita consumption of toilet paper was 3.8 kilograms in 2005. Postavili jsme tak apartmnov dm v Detnm v Orlickch horch. Soubor cookie je nastaven pluginem GDPR Cookie Consent a pouv se k uloen, zda uivatel souhlasil nebo nesouhlasil s pouvnm soubor cookie. An analysis and market research in Europe, Germany was one of the top tissue-consuming countries in Western Europe while Sweden was on top of the per-capita consumption of tissue paper in Western Europe. Did you know that manufacturers don't just use any and all trees to make paper? Recycled paper needs to be washed and is often deinked prior to being pulped. The use of tissue paper is common in developed nations, around 21 million tonnes in North America and 6 million in Europe, and is growing due to urbanization. About 800 rolls of toilet paper are generated from each tree, and about 83 million rolls are produced per day. Ale odhlen nkterch z tchto soubor cookie me ovlivnit v zitek z prohlen. The European market represents around 23% of the global market. Of the total paper and board market tissue accounts for 10%. Kliknutm na Pijmout ve souhlaste s pouvnm VECH soubor cookie. The tissue is then perforated by doctor blades, enabling the sheets to be easily pulled apart. An example of an organization that sets standards is the Forest Stewardship Council. These are used for wrapping/packing various items, cushioning fragile items, stuffing in shoes/bags etc. A plat to i pro finance.Vzeli jsme ze zkuenost s investicemi do spolenost, z propojen obchodu a modernch technologi, z naden a z talentu na architekturu, stavebnictv a nkup perspektivnch pozemk.Vlastnmu podnikn se vnujeme od poloviny prvn dekdy stolet. Chlorine, the most harmful of these poisons, is used to process the most traditional one. Tyto soubory cookie budou ve vaem prohlei uloeny pouze s vam souhlasem. The high-speed, shear cut process is unique and has the highest recyclable output. Colored paper napkins can be a source of carcinogenic primary aromatic amines (paAs) when used as a wrapper for food as a result of degradation of Azo compounds used as paper dyes. Water, tree pulp, fiber extraction chemicals, and bleach are the essential ingredients in toilet paper production (e.g.

From lino cutting to surfing to childrens mental health, their hobbies and interests range far and wide. ETS was founded in 1971 and is based in Brussels since 1992. The term is commonly used to refer to the type of facial tissue, usually sold in boxes, that is designed to facilitate the expulsion of nasal mucus although it may refer to other types of facial tissues including napkins and wipes. ", "Flushing Forests | Worldwatch Institute", "Don't flush forests down the toilet | WWF", "Sustainability and Absorbent Hygiene Products", "Sustainable Use of New and Recovered Fibre Types", "The Issue with Tissue: How Americans Are Flushing Forests Down the Toilet", https://en.wikipedia.org/w/index.php?title=Tissue_paper&oldid=1090095776, Articles with unsourced statements from November 2018, Creative Commons Attribution-ShareAlike License 3.0, Manage deinked sludge in order to maximise beneficial applications and minimise waste burden on society; and. The Yankee cylinder is sprayed with adhesives to make the paper stick. Copyright 2022 Kidadl Ltd. All Rights Reserved. After that, the paper is pressed and dried to the desired moisture level (content about 5%).

The pulp is poured uniformly and consistently across the width of the belt/drum. When Should You Use Auto Title Loans For Business Purposes? These are based on the manufacturers or retailers own declarations. Pohybovali jsme se ve stavebnictv, investovali do zadluench firem a nemovitost. All the water escapes through the pores, leaving just the fibres on the belt in the form of a delicate fabric. Since then, it has been utilized for bathroom purposes. If toilet paper is made of recycled paper, process starts by many different kinds of paper being mixed together. Soubor cookie se pouv k uloen souhlasu uivatele s pouvnm soubor cookie v kategorii Analytika. They have been refined over the years, especially for softness and strength, but their basic design has remained constant. Toilet paper is made from a variety of tissue paper, including recyclable paper, virgin wood pulp, and hemp plants. V plnu mme ti developersk projekty v hodnot 300 milion korun. Today each person in Western Europe uses about 200 tissue handkerchiefs a year, with a variety of 'alternative' functions including the treatment of minor wounds, the cleaning of face and hands and the cleaning of spectacles. Investigate opportunities for alternative product disposal systems that minimize the environmental impact of used products.

[15] A massive pressure cooker (a digester) cooks the wood chips with other chemicals for approximately 3 hours. Tyto soubory cookie pomhaj poskytovat informace o metrikch potu nvtvnk, me okamitho oputn, zdroji nvtvnosti atd. Mete vak navtvit Nastaven soubor cookie a poskytnout kontrolovan souhlas. The bark of trees is taken away. The pulp is what is used to make paper. The sealants require upwards of 40 minutes to cure enough to not stick onto passing traffic. There are opportunities to minimise environmental impacts when using each fibre type. In the United States alone, the majority of roll or sheet production is for bathroom use. It is generally used printed with the manufacturers brand name or, logo to enhance the look and aesthetic appeal of the product. The paper stock is sprayed over mesh screens that allow the water to drain. Recovered fibres now represent some 46.5% of the paper industry's raw materials.

Despite the fact that paper has been used in China for different purposes for a long time, the first use of toilet paper dates back thousands of years. BPA, an endocrine disruptor, materials used in recycled newspaper are toxic in nature. As bamboo grows faster and bamboo requires less environmental supplies for growth, industrially accessible bamboo toilet paper is better for the environment than virgin pulpwood.

The paper is made up of long threads that give it strength. Finally, the paper logs are rolled onto parcels and packaged. Metal blades scrape the paper off as it's coiled on enormous reels. The paper breaks down and disappears in the following days. 5. Trees are stripped of their bark. A jde o investice a developersk projekty, poctiv devostavby nebo teba uzeniny a lahdky. The paper manufacturers try to find a compromise between durability and a fine writing surface on their product. If the toilet paper is made from recycled paper it beings by mixing several different kinds of used paper being mixed and mashed together. Global paper and board industry is in transition", Homepage Producer for Sanitary Paper toilet paper, tissues, kitchen towels and napkins, "Does your toilet paper cause rain forest destruction?

Well known amongst these are claims of "100% recycled" in relation to tissue/paper. Neukld dn osobn daje. At the end of process toilet paper is bleached and scented. The toilet paper manufacturing process starts by creating a paper. It's usually sold as a roll of perforated paper that's swaddled around a cardboard core and kept in a dispenser next to the toilet. The tissue is then transferred on to a massive heated roller called a Yankee. Most toilet paper sold in the commercial world nowadays is designed to degrade in septic tanks, so it is recyclable. In 2019, the NRDC and Stand.earth released a report grading various brands of toilet paper, paper towels, and facial tissue; the report criticized major brands for lacking recycled material.[31]. The data supplied by the manufacturing companies are also independently reviewed. There are numerous methods to utilize toilet paper due to its widespread availability in homes. Tissue paper is a lightweight paper, or a crepe paper, which can be made from recycled paper pulp among other materials. The manufacturing steps include preparation, deconstruction, digestions, cleaning, pre-production pressing, production, rolling for roll formation, and finally cutting. The crinkle (crping) is controlled by the strength of the adhesive, geometry of the doctor blade, speed difference between the Yankee and final section of the paper machine and paper pulp characteristics.[2]. Market Study. Cookies slou k uloen souhlasu uivatele s cookies v kategorii Nezbytn. The paper is scraped off with metal blades and wound on jumbo reels. The difference between virgin paper goods (produced from chopped wood) and those made from recycled toilet paper is the most significant difference in making toilet paper. They are passionate about turning your everyday moments into memories and bringing you inspiring ideas to have fun with your family. Normally such paper towels are two-ply. Type III: ISO 14025 By 2016, some companies had initiated public awareness campaigns instructing residents not to flush discarded wipes. The tissue paper manufacturing process only varies slightly from that of other papers.

Sitemap 6

The industry contributes less than 0.5% of all solid waste and around 2% of municipal solid waste (MSW) compared with paper and board, garden waste and food waste which each comprise between 18 and 20 percent of MSW.[28]. Toilet paper is a kind of tissue paper that is used in every household for cleanliness or to maintain hygiene and is similar to facial tissue. to keep shape intact or, for inserting in garments etc. The main materials used to prodcue toilet paper include: Photo Credit: Juan Arredondo for The New York Times. 9. In North America, people are consuming around three times as much tissue as in Europe. So there are two types of toilet paper manufacturing. Andrex was the first paper company to make moist toilet paper, sometimes known as 'Wet Wipes,' in the United Kingdom in the 1990s. [11], Tissue paper, in the form of standard single-ply toilet paper, is commonly used in road repair to protect crack sealants. The tissue can then be made into either flat surfaces or wound around a cardboard tube to create a cylindrical rolls.

The industry contributes less than 0.5% of all solid waste and around 2% of municipal solid waste (MSW) compared with paper and board, garden waste and food waste which each comprise between 18 and 20 percent of MSW.[28]. Toilet paper is a kind of tissue paper that is used in every household for cleanliness or to maintain hygiene and is similar to facial tissue. to keep shape intact or, for inserting in garments etc. The main materials used to prodcue toilet paper include: Photo Credit: Juan Arredondo for The New York Times. 9. In North America, people are consuming around three times as much tissue as in Europe. So there are two types of toilet paper manufacturing. Andrex was the first paper company to make moist toilet paper, sometimes known as 'Wet Wipes,' in the United Kingdom in the 1990s. [11], Tissue paper, in the form of standard single-ply toilet paper, is commonly used in road repair to protect crack sealants. The tissue can then be made into either flat surfaces or wound around a cardboard tube to create a cylindrical rolls.  [20] Dal nekategorizovan soubory cookie jsou ty, kter jsou analyzovny a dosud nebyly zaazeny do dn kategorie. Toilet paper is then pulverized and reformed into very thin and soft paper. Toilet paper is made from recyclable paper which has a lower environmental impact than that made from virgin paper. Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. After that, the tissue paper is often pressed, embossed, scented, perforated, and/or colored. The logs are carefully debarked with machine to leave as much wood as possible. The moisture in the wood is evaporated and the mass is reduces to cellulose fibers, lignin and other substances. You can tell a Paper Profile meets the Type III requirements when the verifiers logo is included on the document.[32]. To leave as much wood as possible, the logs are meticulously debarked with a machine. Kidadl is supported by you, the reader. Preparing trees (a combination of softwood and hardwood trees). Investin skupina specializujc se primrn na developersk projekty.

[20] Dal nekategorizovan soubory cookie jsou ty, kter jsou analyzovny a dosud nebyly zaazeny do dn kategorie. Toilet paper is then pulverized and reformed into very thin and soft paper. Toilet paper is made from recyclable paper which has a lower environmental impact than that made from virgin paper. Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. After that, the tissue paper is often pressed, embossed, scented, perforated, and/or colored. The logs are carefully debarked with machine to leave as much wood as possible. The moisture in the wood is evaporated and the mass is reduces to cellulose fibers, lignin and other substances. You can tell a Paper Profile meets the Type III requirements when the verifiers logo is included on the document.[32]. To leave as much wood as possible, the logs are meticulously debarked with a machine. Kidadl is supported by you, the reader. Preparing trees (a combination of softwood and hardwood trees). Investin skupina specializujc se primrn na developersk projekty.

Funkn soubory cookie pomhaj provdt urit funkce, jako je sdlen obsahu webovch strnek na platformch socilnch mdi, shromaovn zptn vazby a dal funkce tetch stran. To give the toilet paper a pure white color, companies use chlorine. Be the first to know about new B2B SaaS Marketing insights to build or refine your marketing function with the tools and knowledge of todays industry. Stirring together these fine retted flakes in a mixer tank with a large quantity of water and other chemicals generates. Hardwood trees with shorter strands, such as maple and oak, produce soft paper. Paper is sometimes created from recycled materials, but materials like virgin tree pulp is also used. [9][11] The authors of a study for Studio Sound magazine suggested that had the speakers' grilles been used in studios, they would have had the same effect on the treble output as the improvised tissue paper filter. Mte tak monost odhlsit se z tchto soubor cookie. 10. When Scott paper, one of the paper companies, began producing toilet paper on rolls in 1890, it became popular. As a result, the industry has often been scrutinized for deforestation. A life-cycle assessment study indicated that neither fibre type can be considered environmentally preferable. In North and South America, companies cut down many trees, causing environmental issues. Improve energy efficiency in tissue manufacturing; Examine opportunities for changing to alternative, non fossil based sources, of, Deliver products that maximise functionality and optimize consumption; and. 2. During the early time, Zhejiang generated millions of sheets of toilet paper per year. The tissue production process upis basedon the manufacturing of raw material such as virgin pulp and waste paper. The history of toilet paper dates back to the Tang and the Ming dynasty. Whitening with oxygen, ozone, or sodium gas is a common practice in the recycling industry. Lignin, the glue that holds fibers together, must be removed from the pulp or the papers would yellow over time. 4. Softwood and hardwood trees are used to make virgin-fiber toilet paper. Unlike dry toilet paper rolls, moist toilet paper swiftly decomposes in the environment. To make paper stock, the company combines pulp with a large amount of water (99.5% final moisture and 0.5% fiber). S fortelem. 3. Companies will use various forms of solutions to do this, but it all needs to be washed and deinked prior to being pulped. In 2015, the global market for tissue paper is growing at per annum rates between 89% (China, currently 40% of global market) and 23% (Europe). [17], In Europe, the industry is represented by the European Tissue Symposium (ETS), a trade association. The properties are controlled by pulp quality, crping and additives (both in base paper and as coating). Paper Converting Machinery Selection and Best Buying Guide, 4 Different Types of Paper Stocks for Printing, Importance of Adsorption Chillers in Various Industries. In 2002, it noted that "a little over 60% of the pulp and paper produced in Europe comes from mills certified under one of the internationally recognised eco-management schemes". The wood chips are separated into batches. [19], Tissue paper production and consumption is predicted to continue to grow because of factors like urbanization, increasing disposable incomes and consumer spending. The prepared pulp is then poured over fast moving belts made from highly porous materials that are driven over huge drums heated by steam. Toilet paper is largely made of chemical pulp, but it all starts with paper. Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. Pouvme tak soubory cookie tetch stran, kter nm pomhaj analyzovat a porozumt tomu, jak tento web pouvte. However, most toilet paper today is made from a chemical pulp. Toilet paper was first used by a Chinese emperor in medieval China, who utilized sheets of paper. Facial tissue (paper handkerchiefs) refers to a class of soft, absorbent, disposable paper that is suitable for use on the face. Analytick soubory cookie se pouvaj k pochopen toho, jak nvtvnci interaguj s webem. European Disposables and Nonwoven Association, Toilet paper Environmental considerations, Confederation of European Paper Industries, "Yamaha's NS-10: The Most Important Speaker You've Never Heard Of", 1977 Yamaha NS-10M Speakers|Mix Inducts the Yamaha NS10M Speakers into the TECnology Hall of Fame, "The Yamaha NS10M: Twenty Years a Reference Monitor. Garantujeme zhodnocen pinejmenm 7,2 procenta.

Funkn soubory cookie pomhaj provdt urit funkce, jako je sdlen obsahu webovch strnek na platformch socilnch mdi, shromaovn zptn vazby a dal funkce tetch stran. To give the toilet paper a pure white color, companies use chlorine. Be the first to know about new B2B SaaS Marketing insights to build or refine your marketing function with the tools and knowledge of todays industry. Stirring together these fine retted flakes in a mixer tank with a large quantity of water and other chemicals generates. Hardwood trees with shorter strands, such as maple and oak, produce soft paper. Paper is sometimes created from recycled materials, but materials like virgin tree pulp is also used. [9][11] The authors of a study for Studio Sound magazine suggested that had the speakers' grilles been used in studios, they would have had the same effect on the treble output as the improvised tissue paper filter. Mte tak monost odhlsit se z tchto soubor cookie. 10. When Scott paper, one of the paper companies, began producing toilet paper on rolls in 1890, it became popular. As a result, the industry has often been scrutinized for deforestation. A life-cycle assessment study indicated that neither fibre type can be considered environmentally preferable. In North and South America, companies cut down many trees, causing environmental issues. Improve energy efficiency in tissue manufacturing; Examine opportunities for changing to alternative, non fossil based sources, of, Deliver products that maximise functionality and optimize consumption; and. 2. During the early time, Zhejiang generated millions of sheets of toilet paper per year. The tissue production process upis basedon the manufacturing of raw material such as virgin pulp and waste paper. The history of toilet paper dates back to the Tang and the Ming dynasty. Whitening with oxygen, ozone, or sodium gas is a common practice in the recycling industry. Lignin, the glue that holds fibers together, must be removed from the pulp or the papers would yellow over time. 4. Softwood and hardwood trees are used to make virgin-fiber toilet paper. Unlike dry toilet paper rolls, moist toilet paper swiftly decomposes in the environment. To make paper stock, the company combines pulp with a large amount of water (99.5% final moisture and 0.5% fiber). S fortelem. 3. Companies will use various forms of solutions to do this, but it all needs to be washed and deinked prior to being pulped. In 2015, the global market for tissue paper is growing at per annum rates between 89% (China, currently 40% of global market) and 23% (Europe). [17], In Europe, the industry is represented by the European Tissue Symposium (ETS), a trade association. The properties are controlled by pulp quality, crping and additives (both in base paper and as coating). Paper Converting Machinery Selection and Best Buying Guide, 4 Different Types of Paper Stocks for Printing, Importance of Adsorption Chillers in Various Industries. In 2002, it noted that "a little over 60% of the pulp and paper produced in Europe comes from mills certified under one of the internationally recognised eco-management schemes". The wood chips are separated into batches. [19], Tissue paper production and consumption is predicted to continue to grow because of factors like urbanization, increasing disposable incomes and consumer spending. The prepared pulp is then poured over fast moving belts made from highly porous materials that are driven over huge drums heated by steam. Toilet paper is largely made of chemical pulp, but it all starts with paper. Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. Pouvme tak soubory cookie tetch stran, kter nm pomhaj analyzovat a porozumt tomu, jak tento web pouvte. However, most toilet paper today is made from a chemical pulp. Toilet paper was first used by a Chinese emperor in medieval China, who utilized sheets of paper. Facial tissue (paper handkerchiefs) refers to a class of soft, absorbent, disposable paper that is suitable for use on the face. Analytick soubory cookie se pouvaj k pochopen toho, jak nvtvnci interaguj s webem. European Disposables and Nonwoven Association, Toilet paper Environmental considerations, Confederation of European Paper Industries, "Yamaha's NS-10: The Most Important Speaker You've Never Heard Of", 1977 Yamaha NS-10M Speakers|Mix Inducts the Yamaha NS10M Speakers into the TECnology Hall of Fame, "The Yamaha NS10M: Twenty Years a Reference Monitor. Garantujeme zhodnocen pinejmenm 7,2 procenta.

All the pulp come from certificated forests. Manufacturers created it from trees, that is, from small pieces of virgin paper fiber which is made from a mix of softwood and hardwood trees. Less than 1% of all commercial wood production ends up as wood pulp in absorbent hygiene products. while packing/folding to keep them wrinkle free and safe.

All the pulp come from certificated forests. Manufacturers created it from trees, that is, from small pieces of virgin paper fiber which is made from a mix of softwood and hardwood trees. Less than 1% of all commercial wood production ends up as wood pulp in absorbent hygiene products. while packing/folding to keep them wrinkle free and safe.  Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. [7], In the late 1970s and early 1980s, a sound recording engineer named Bob Clearmountain was said to have hung tissue paper over the tweeter of his pair of Yamaha NS-10 speakers to tame the over-bright treble coming from it. The biggest difference between toilet papers is the distinction between virgin paper products (formed from chipped wood) and those made from recycled paper. The tissue is taken and its plies are split and passed through an embossing roller. The lignin and heating chemicals are then removed from the pulp. For information please visit the page about tissue production. It is bleached and scented at the conclusion of the procedure. 8. Creping is done by the Yankee's doctor blade that is scraping the dry paper off the cylinder surface. The trees are broken down into usable fiber by water and chemicals. By continuing to browse this website you accept the use of cookies. This page was last edited on 27 May 2022, at 10:26. Zajmaj vs investice do developerskch projekt? The paper is then fed into machines that perforate it into squares and cut it into long strips. It is a type of thin, translucent paper generally in the range of grammages between 17 and 40 GSM, that can be rough or, shining, hard or soft, depending upon the nature of use. Malm i vtm investorm nabzme monost zajmav zhodnotit penze. In this study both new fibre and recovered fibre offer environmental benefits and shortcomings. Finally, the paper logs are cut into rolls and wrapped packages. Adjust the draw speed of the roll can let you get a thicker or thinner tissue as per your goal. [4], The importance of the paper tissue on minimising the spread of an infection has been highlighted in light of fears over a swine flu epidemic. Pressure on use of tissue papers has grown in the wake of improved hygiene concerns in response to the coronavirus pandemic. pedevm do rezidennch developerskch projekt. ", "Examining the Yamaha NS-10M 'Tissue Paper Phenomenon' An Analysis of the Industry-Wide Practice of Using a Tissue-Paper Layer to Reduce High-Frequency Output", "Littleton TP's its own streets as a way to fill its cracks single-ply only", "City crews hitting the streets with single-ply toilet paper", "Is tissue becoming a safe haven for the global pulp and paper industry? Toilet paper comes in a variety of thicknesses and roll sizes.

Tento soubor cookie je nastaven pluginem GDPR Cookie Consent. [7], In the late 1970s and early 1980s, a sound recording engineer named Bob Clearmountain was said to have hung tissue paper over the tweeter of his pair of Yamaha NS-10 speakers to tame the over-bright treble coming from it. The biggest difference between toilet papers is the distinction between virgin paper products (formed from chipped wood) and those made from recycled paper. The tissue is taken and its plies are split and passed through an embossing roller. The lignin and heating chemicals are then removed from the pulp. For information please visit the page about tissue production. It is bleached and scented at the conclusion of the procedure. 8. Creping is done by the Yankee's doctor blade that is scraping the dry paper off the cylinder surface. The trees are broken down into usable fiber by water and chemicals. By continuing to browse this website you accept the use of cookies. This page was last edited on 27 May 2022, at 10:26. Zajmaj vs investice do developerskch projekt? The paper is then fed into machines that perforate it into squares and cut it into long strips. It is a type of thin, translucent paper generally in the range of grammages between 17 and 40 GSM, that can be rough or, shining, hard or soft, depending upon the nature of use. Malm i vtm investorm nabzme monost zajmav zhodnotit penze. In this study both new fibre and recovered fibre offer environmental benefits and shortcomings. Finally, the paper logs are cut into rolls and wrapped packages. Adjust the draw speed of the roll can let you get a thicker or thinner tissue as per your goal. [4], The importance of the paper tissue on minimising the spread of an infection has been highlighted in light of fears over a swine flu epidemic. Pressure on use of tissue papers has grown in the wake of improved hygiene concerns in response to the coronavirus pandemic. pedevm do rezidennch developerskch projekt. ", "Examining the Yamaha NS-10M 'Tissue Paper Phenomenon' An Analysis of the Industry-Wide Practice of Using a Tissue-Paper Layer to Reduce High-Frequency Output", "Littleton TP's its own streets as a way to fill its cracks single-ply only", "City crews hitting the streets with single-ply toilet paper", "Is tissue becoming a safe haven for the global pulp and paper industry? Toilet paper comes in a variety of thicknesses and roll sizes.  The paper roll is made up of long threads that give it strength. Recyclable paper pulp (fibers) and water, along with chemicals such as sulfurate assist the paper degradation and starches which make it tough and durable when moist are used to make white toilet paper. For the first time, in the sixth century BC, paper was used in China for hygiene or washing in spite of its invention being in the second century BC. By joining Kidadl you agree to Kidadls. Nezbytn soubory cookie jsou naprosto nezbytn pro sprvn fungovn webu. Next step is choosing a solution to remove ink. These papers contain high amounts of NBSK and CTMP. Type I: ISO 14024

The paper roll is made up of long threads that give it strength. Recyclable paper pulp (fibers) and water, along with chemicals such as sulfurate assist the paper degradation and starches which make it tough and durable when moist are used to make white toilet paper. For the first time, in the sixth century BC, paper was used in China for hygiene or washing in spite of its invention being in the second century BC. By joining Kidadl you agree to Kidadls. Nezbytn soubory cookie jsou naprosto nezbytn pro sprvn fungovn webu. Next step is choosing a solution to remove ink. These papers contain high amounts of NBSK and CTMP. Type I: ISO 14024  Other materials for final product of toilet paper include water, chemicals and bleaches. Ve dvou etapch postavme devatenct dom v hodnot pes 120 milion korun. How Manufacturing Companies Can Use Apps to Reduce Paper Waste, Use of Industrial Conveyors in the Pulp and Paper Industry, Use of water treatment products in the paper industry, Avoiding Expensive Mistakes: Testing Your Tools for Automated Print Jobs, CNC Tooling for the Paper & Pulp Industry. By joining Kidadl you agree to Kidadls Terms of Use and Privacy Policy and consent to receiving marketing communications from Kidadl. [16], The European tissue market is worth approximately 10 billion Euros annually and is growing at a rate of around 3%. Forms of paper used in the production of tissue paper can include various forms of recylced paper, virgin tree pulp, as well as hemp plants. Today, more than 20 billion rolls of toilet tissue are used each year in Western Europe.[4]. It is created from virgin wood fibers or a mixture of recycled paper pulp and water, together with chemical sulfates mixed to help it break down fibers, starches mixed for wet strength, and chlorine to make it white.

Other materials for final product of toilet paper include water, chemicals and bleaches. Ve dvou etapch postavme devatenct dom v hodnot pes 120 milion korun. How Manufacturing Companies Can Use Apps to Reduce Paper Waste, Use of Industrial Conveyors in the Pulp and Paper Industry, Use of water treatment products in the paper industry, Avoiding Expensive Mistakes: Testing Your Tools for Automated Print Jobs, CNC Tooling for the Paper & Pulp Industry. By joining Kidadl you agree to Kidadls Terms of Use and Privacy Policy and consent to receiving marketing communications from Kidadl. [16], The European tissue market is worth approximately 10 billion Euros annually and is growing at a rate of around 3%. Forms of paper used in the production of tissue paper can include various forms of recylced paper, virgin tree pulp, as well as hemp plants. Today, more than 20 billion rolls of toilet tissue are used each year in Western Europe.[4]. It is created from virgin wood fibers or a mixture of recycled paper pulp and water, together with chemical sulfates mixed to help it break down fibers, starches mixed for wet strength, and chlorine to make it white.  The paper stock is sprayed onto screens of mesh that drain the water. Trees are logged and cut into chips, which are then are ground into fine flakes, which are then soaked and pulled-apart (retted). Manage the raw material sources to maintain legal, sustainable forestry practices by implementing processes such as.

The paper stock is sprayed onto screens of mesh that drain the water. Trees are logged and cut into chips, which are then are ground into fine flakes, which are then soaked and pulled-apart (retted). Manage the raw material sources to maintain legal, sustainable forestry practices by implementing processes such as.  Colored and white stock with staples are used. It shields the hands from damage while they are being processed. Eco-labelling entered mainstream environmental policy-making in the late seventies, first with national schemes such as the German Blue Angel programme, to be followed by the Nordic swan (1989). A v plnu mme celou adu dalch vc. Every day, 27,000 trees are cut down for toilet paper production around the world. The one that has European application is the EU Flower. The pulp is what paper is made from. This gives a bulky paper with high wet tensile strength and good water holding capacity. Cookie se pouv k uloen souhlasu uivatele s cookies v kategorii Jin". Sometimes known as EPDs (Environmental Product Declarations), these labels are based on an independent review of the life cycle of the product. Select the recovered paper depending on the end-product requirements and that also allows the most efficient recycling process. Total environmental impacts vary case by case, depending on for example the location of the tissue paper mill, availability of fibres close to the mill, energy options and waste utilization possibilities.

Colored and white stock with staples are used. It shields the hands from damage while they are being processed. Eco-labelling entered mainstream environmental policy-making in the late seventies, first with national schemes such as the German Blue Angel programme, to be followed by the Nordic swan (1989). A v plnu mme celou adu dalch vc. Every day, 27,000 trees are cut down for toilet paper production around the world. The one that has European application is the EU Flower. The pulp is what paper is made from. This gives a bulky paper with high wet tensile strength and good water holding capacity. Cookie se pouv k uloen souhlasu uivatele s cookies v kategorii Jin". Sometimes known as EPDs (Environmental Product Declarations), these labels are based on an independent review of the life cycle of the product. Select the recovered paper depending on the end-product requirements and that also allows the most efficient recycling process. Total environmental impacts vary case by case, depending on for example the location of the tissue paper mill, availability of fibres close to the mill, energy options and waste utilization possibilities.  Paper towels are the second largest application for tissue paper in the consumer sector. Its specific primary energy consumption has decreased by 16% and the specific electricity consumption has decreased by 11%, due to measures such as improved process technology and investment in combined heat and power (CHP). Once consumed, most forest-based paper products start a new life as recycled material or biofuel[27], EDANA, the trade body for the non-woven absorbent hygiene products industry (which includes products such as household wipes for use in the home) has reported annually on the industry's environmental performance since 2005. However, more companies are presently using more recycled fibres in tissue paper. The chemicals used in the making are ozone, peroxide, oxygen, and sodium hydroxide or peroxide for the paper to be bleached. In the same year, 15,000 sheets of scented toilet paper with a special soft-fabric sheet backing were manufactured. It is actually a process of using both hardwood and softwood from "virgin" trees.

Paper towels are the second largest application for tissue paper in the consumer sector. Its specific primary energy consumption has decreased by 16% and the specific electricity consumption has decreased by 11%, due to measures such as improved process technology and investment in combined heat and power (CHP). Once consumed, most forest-based paper products start a new life as recycled material or biofuel[27], EDANA, the trade body for the non-woven absorbent hygiene products industry (which includes products such as household wipes for use in the home) has reported annually on the industry's environmental performance since 2005. However, more companies are presently using more recycled fibres in tissue paper. The chemicals used in the making are ozone, peroxide, oxygen, and sodium hydroxide or peroxide for the paper to be bleached. In the same year, 15,000 sheets of scented toilet paper with a special soft-fabric sheet backing were manufactured. It is actually a process of using both hardwood and softwood from "virgin" trees.  The plies are removed and held together with glue. Subscribe and take advantage of this platform. Toxins like dioxin and furans are produced when chlorine bleach is used. The heat of the Yankee makes the fabric dry almost instantly. The combination of hardwood to softwood is approximetly 30% softwood and 70% hardwood. So there are two kind of manufacturing process for the toilet paper. [18], In the U.S., the tissue industry is organized in the AF&PA.

The plies are removed and held together with glue. Subscribe and take advantage of this platform. Toxins like dioxin and furans are produced when chlorine bleach is used. The heat of the Yankee makes the fabric dry almost instantly. The combination of hardwood to softwood is approximetly 30% softwood and 70% hardwood. So there are two kind of manufacturing process for the toilet paper. [18], In the U.S., the tissue industry is organized in the AF&PA.  Copyright 2018 Pulp and Paper Technology. Custom-printed wrapping tissue is becoming a popular trend for boutique retail businesses. To give the toilet paper it's pure white color companies use various methods to achieve this including ozone, peroxide, oxygen and/or sodium hydroxide. The industry relies heavily on biofuels (about 50% of its primary energy). 6.

Copyright 2018 Pulp and Paper Technology. Custom-printed wrapping tissue is becoming a popular trend for boutique retail businesses. To give the toilet paper it's pure white color companies use various methods to achieve this including ozone, peroxide, oxygen and/or sodium hydroxide. The industry relies heavily on biofuels (about 50% of its primary energy). 6.  [25][26], Meanwhile, the paper tissue industry, along with the rest of the paper manufacturing sector, has worked to minimise its impact on the environment. Tissue can be made from recycled paper pulp on a paper machine. Soubor cookie je nastaven na zklad souhlasu s cookie GDPR k zaznamenn souhlasu uivatele pro soubory cookie v kategorii Funkn. Obrat skupiny v roce 2020 doshnul 204 milion korun. Zhodnotme mal, vt i velk prostedky prostednictvm zajmavch projekt od rodinnch devostaveb po velk rezidenn a bytov domy. Batches of wood chips are separated. The wood's moisture evaporates, reducing the bulk to cellulose fibers, lignin, and other components. [24] According to the Worldwatch Institute, the world per capita consumption of toilet paper was 3.8 kilograms in 2005. Postavili jsme tak apartmnov dm v Detnm v Orlickch horch. Soubor cookie je nastaven pluginem GDPR Cookie Consent a pouv se k uloen, zda uivatel souhlasil nebo nesouhlasil s pouvnm soubor cookie. An analysis and market research in Europe, Germany was one of the top tissue-consuming countries in Western Europe while Sweden was on top of the per-capita consumption of tissue paper in Western Europe. Did you know that manufacturers don't just use any and all trees to make paper? Recycled paper needs to be washed and is often deinked prior to being pulped. The use of tissue paper is common in developed nations, around 21 million tonnes in North America and 6 million in Europe, and is growing due to urbanization. About 800 rolls of toilet paper are generated from each tree, and about 83 million rolls are produced per day. Ale odhlen nkterch z tchto soubor cookie me ovlivnit v zitek z prohlen. The European market represents around 23% of the global market. Of the total paper and board market tissue accounts for 10%. Kliknutm na Pijmout ve souhlaste s pouvnm VECH soubor cookie. The tissue is then perforated by doctor blades, enabling the sheets to be easily pulled apart. An example of an organization that sets standards is the Forest Stewardship Council. These are used for wrapping/packing various items, cushioning fragile items, stuffing in shoes/bags etc. A plat to i pro finance.Vzeli jsme ze zkuenost s investicemi do spolenost, z propojen obchodu a modernch technologi, z naden a z talentu na architekturu, stavebnictv a nkup perspektivnch pozemk.Vlastnmu podnikn se vnujeme od poloviny prvn dekdy stolet. Chlorine, the most harmful of these poisons, is used to process the most traditional one. Tyto soubory cookie budou ve vaem prohlei uloeny pouze s vam souhlasem. The high-speed, shear cut process is unique and has the highest recyclable output. Colored paper napkins can be a source of carcinogenic primary aromatic amines (paAs) when used as a wrapper for food as a result of degradation of Azo compounds used as paper dyes. Water, tree pulp, fiber extraction chemicals, and bleach are the essential ingredients in toilet paper production (e.g.

[25][26], Meanwhile, the paper tissue industry, along with the rest of the paper manufacturing sector, has worked to minimise its impact on the environment. Tissue can be made from recycled paper pulp on a paper machine. Soubor cookie je nastaven na zklad souhlasu s cookie GDPR k zaznamenn souhlasu uivatele pro soubory cookie v kategorii Funkn. Obrat skupiny v roce 2020 doshnul 204 milion korun. Zhodnotme mal, vt i velk prostedky prostednictvm zajmavch projekt od rodinnch devostaveb po velk rezidenn a bytov domy. Batches of wood chips are separated. The wood's moisture evaporates, reducing the bulk to cellulose fibers, lignin, and other components. [24] According to the Worldwatch Institute, the world per capita consumption of toilet paper was 3.8 kilograms in 2005. Postavili jsme tak apartmnov dm v Detnm v Orlickch horch. Soubor cookie je nastaven pluginem GDPR Cookie Consent a pouv se k uloen, zda uivatel souhlasil nebo nesouhlasil s pouvnm soubor cookie. An analysis and market research in Europe, Germany was one of the top tissue-consuming countries in Western Europe while Sweden was on top of the per-capita consumption of tissue paper in Western Europe. Did you know that manufacturers don't just use any and all trees to make paper? Recycled paper needs to be washed and is often deinked prior to being pulped. The use of tissue paper is common in developed nations, around 21 million tonnes in North America and 6 million in Europe, and is growing due to urbanization. About 800 rolls of toilet paper are generated from each tree, and about 83 million rolls are produced per day. Ale odhlen nkterch z tchto soubor cookie me ovlivnit v zitek z prohlen. The European market represents around 23% of the global market. Of the total paper and board market tissue accounts for 10%. Kliknutm na Pijmout ve souhlaste s pouvnm VECH soubor cookie. The tissue is then perforated by doctor blades, enabling the sheets to be easily pulled apart. An example of an organization that sets standards is the Forest Stewardship Council. These are used for wrapping/packing various items, cushioning fragile items, stuffing in shoes/bags etc. A plat to i pro finance.Vzeli jsme ze zkuenost s investicemi do spolenost, z propojen obchodu a modernch technologi, z naden a z talentu na architekturu, stavebnictv a nkup perspektivnch pozemk.Vlastnmu podnikn se vnujeme od poloviny prvn dekdy stolet. Chlorine, the most harmful of these poisons, is used to process the most traditional one. Tyto soubory cookie budou ve vaem prohlei uloeny pouze s vam souhlasem. The high-speed, shear cut process is unique and has the highest recyclable output. Colored paper napkins can be a source of carcinogenic primary aromatic amines (paAs) when used as a wrapper for food as a result of degradation of Azo compounds used as paper dyes. Water, tree pulp, fiber extraction chemicals, and bleach are the essential ingredients in toilet paper production (e.g.  From lino cutting to surfing to childrens mental health, their hobbies and interests range far and wide. ETS was founded in 1971 and is based in Brussels since 1992. The term is commonly used to refer to the type of facial tissue, usually sold in boxes, that is designed to facilitate the expulsion of nasal mucus although it may refer to other types of facial tissues including napkins and wipes. ", "Flushing Forests | Worldwatch Institute", "Don't flush forests down the toilet | WWF", "Sustainability and Absorbent Hygiene Products", "Sustainable Use of New and Recovered Fibre Types", "The Issue with Tissue: How Americans Are Flushing Forests Down the Toilet", https://en.wikipedia.org/w/index.php?title=Tissue_paper&oldid=1090095776, Articles with unsourced statements from November 2018, Creative Commons Attribution-ShareAlike License 3.0, Manage deinked sludge in order to maximise beneficial applications and minimise waste burden on society; and. The Yankee cylinder is sprayed with adhesives to make the paper stick. Copyright 2022 Kidadl Ltd. All Rights Reserved. After that, the paper is pressed and dried to the desired moisture level (content about 5%).

From lino cutting to surfing to childrens mental health, their hobbies and interests range far and wide. ETS was founded in 1971 and is based in Brussels since 1992. The term is commonly used to refer to the type of facial tissue, usually sold in boxes, that is designed to facilitate the expulsion of nasal mucus although it may refer to other types of facial tissues including napkins and wipes. ", "Flushing Forests | Worldwatch Institute", "Don't flush forests down the toilet | WWF", "Sustainability and Absorbent Hygiene Products", "Sustainable Use of New and Recovered Fibre Types", "The Issue with Tissue: How Americans Are Flushing Forests Down the Toilet", https://en.wikipedia.org/w/index.php?title=Tissue_paper&oldid=1090095776, Articles with unsourced statements from November 2018, Creative Commons Attribution-ShareAlike License 3.0, Manage deinked sludge in order to maximise beneficial applications and minimise waste burden on society; and. The Yankee cylinder is sprayed with adhesives to make the paper stick. Copyright 2022 Kidadl Ltd. All Rights Reserved. After that, the paper is pressed and dried to the desired moisture level (content about 5%).  The pulp is poured uniformly and consistently across the width of the belt/drum. When Should You Use Auto Title Loans For Business Purposes? These are based on the manufacturers or retailers own declarations. Pohybovali jsme se ve stavebnictv, investovali do zadluench firem a nemovitost. All the water escapes through the pores, leaving just the fibres on the belt in the form of a delicate fabric. Since then, it has been utilized for bathroom purposes. If toilet paper is made of recycled paper, process starts by many different kinds of paper being mixed together. Soubor cookie se pouv k uloen souhlasu uivatele s pouvnm soubor cookie v kategorii Analytika. They have been refined over the years, especially for softness and strength, but their basic design has remained constant. Toilet paper is made from a variety of tissue paper, including recyclable paper, virgin wood pulp, and hemp plants. V plnu mme ti developersk projekty v hodnot 300 milion korun. Today each person in Western Europe uses about 200 tissue handkerchiefs a year, with a variety of 'alternative' functions including the treatment of minor wounds, the cleaning of face and hands and the cleaning of spectacles. Investigate opportunities for alternative product disposal systems that minimize the environmental impact of used products.

The pulp is poured uniformly and consistently across the width of the belt/drum. When Should You Use Auto Title Loans For Business Purposes? These are based on the manufacturers or retailers own declarations. Pohybovali jsme se ve stavebnictv, investovali do zadluench firem a nemovitost. All the water escapes through the pores, leaving just the fibres on the belt in the form of a delicate fabric. Since then, it has been utilized for bathroom purposes. If toilet paper is made of recycled paper, process starts by many different kinds of paper being mixed together. Soubor cookie se pouv k uloen souhlasu uivatele s pouvnm soubor cookie v kategorii Analytika. They have been refined over the years, especially for softness and strength, but their basic design has remained constant. Toilet paper is made from a variety of tissue paper, including recyclable paper, virgin wood pulp, and hemp plants. V plnu mme ti developersk projekty v hodnot 300 milion korun. Today each person in Western Europe uses about 200 tissue handkerchiefs a year, with a variety of 'alternative' functions including the treatment of minor wounds, the cleaning of face and hands and the cleaning of spectacles. Investigate opportunities for alternative product disposal systems that minimize the environmental impact of used products.  [15] A massive pressure cooker (a digester) cooks the wood chips with other chemicals for approximately 3 hours. Tyto soubory cookie pomhaj poskytovat informace o metrikch potu nvtvnk, me okamitho oputn, zdroji nvtvnosti atd. Mete vak navtvit Nastaven soubor cookie a poskytnout kontrolovan souhlas. The bark of trees is taken away. The pulp is what is used to make paper. The sealants require upwards of 40 minutes to cure enough to not stick onto passing traffic. There are opportunities to minimise environmental impacts when using each fibre type. In the United States alone, the majority of roll or sheet production is for bathroom use. It is generally used printed with the manufacturers brand name or, logo to enhance the look and aesthetic appeal of the product. The paper stock is sprayed over mesh screens that allow the water to drain. Recovered fibres now represent some 46.5% of the paper industry's raw materials.

[15] A massive pressure cooker (a digester) cooks the wood chips with other chemicals for approximately 3 hours. Tyto soubory cookie pomhaj poskytovat informace o metrikch potu nvtvnk, me okamitho oputn, zdroji nvtvnosti atd. Mete vak navtvit Nastaven soubor cookie a poskytnout kontrolovan souhlas. The bark of trees is taken away. The pulp is what is used to make paper. The sealants require upwards of 40 minutes to cure enough to not stick onto passing traffic. There are opportunities to minimise environmental impacts when using each fibre type. In the United States alone, the majority of roll or sheet production is for bathroom use. It is generally used printed with the manufacturers brand name or, logo to enhance the look and aesthetic appeal of the product. The paper stock is sprayed over mesh screens that allow the water to drain. Recovered fibres now represent some 46.5% of the paper industry's raw materials.  Despite the fact that paper has been used in China for different purposes for a long time, the first use of toilet paper dates back thousands of years. BPA, an endocrine disruptor, materials used in recycled newspaper are toxic in nature. As bamboo grows faster and bamboo requires less environmental supplies for growth, industrially accessible bamboo toilet paper is better for the environment than virgin pulpwood.

Despite the fact that paper has been used in China for different purposes for a long time, the first use of toilet paper dates back thousands of years. BPA, an endocrine disruptor, materials used in recycled newspaper are toxic in nature. As bamboo grows faster and bamboo requires less environmental supplies for growth, industrially accessible bamboo toilet paper is better for the environment than virgin pulpwood.  The paper is made up of long threads that give it strength. Finally, the paper logs are rolled onto parcels and packaged. Metal blades scrape the paper off as it's coiled on enormous reels. The paper breaks down and disappears in the following days. 5. Trees are stripped of their bark. A jde o investice a developersk projekty, poctiv devostavby nebo teba uzeniny a lahdky. The paper manufacturers try to find a compromise between durability and a fine writing surface on their product. If the toilet paper is made from recycled paper it beings by mixing several different kinds of used paper being mixed and mashed together. Global paper and board industry is in transition", Homepage Producer for Sanitary Paper toilet paper, tissues, kitchen towels and napkins, "Does your toilet paper cause rain forest destruction?

The paper is made up of long threads that give it strength. Finally, the paper logs are rolled onto parcels and packaged. Metal blades scrape the paper off as it's coiled on enormous reels. The paper breaks down and disappears in the following days. 5. Trees are stripped of their bark. A jde o investice a developersk projekty, poctiv devostavby nebo teba uzeniny a lahdky. The paper manufacturers try to find a compromise between durability and a fine writing surface on their product. If the toilet paper is made from recycled paper it beings by mixing several different kinds of used paper being mixed and mashed together. Global paper and board industry is in transition", Homepage Producer for Sanitary Paper toilet paper, tissues, kitchen towels and napkins, "Does your toilet paper cause rain forest destruction?  Well known amongst these are claims of "100% recycled" in relation to tissue/paper. Neukld dn osobn daje. At the end of process toilet paper is bleached and scented. The toilet paper manufacturing process starts by creating a paper. It's usually sold as a roll of perforated paper that's swaddled around a cardboard core and kept in a dispenser next to the toilet. The tissue is then transferred on to a massive heated roller called a Yankee. Most toilet paper sold in the commercial world nowadays is designed to degrade in septic tanks, so it is recyclable. In 2019, the NRDC and Stand.earth released a report grading various brands of toilet paper, paper towels, and facial tissue; the report criticized major brands for lacking recycled material.[31]. The data supplied by the manufacturing companies are also independently reviewed. There are numerous methods to utilize toilet paper due to its widespread availability in homes. Tissue paper is a lightweight paper, or a crepe paper, which can be made from recycled paper pulp among other materials. The manufacturing steps include preparation, deconstruction, digestions, cleaning, pre-production pressing, production, rolling for roll formation, and finally cutting. The crinkle (crping) is controlled by the strength of the adhesive, geometry of the doctor blade, speed difference between the Yankee and final section of the paper machine and paper pulp characteristics.[2]. Market Study. Cookies slou k uloen souhlasu uivatele s cookies v kategorii Nezbytn. The paper is scraped off with metal blades and wound on jumbo reels. The difference between virgin paper goods (produced from chopped wood) and those made from recycled toilet paper is the most significant difference in making toilet paper. They are passionate about turning your everyday moments into memories and bringing you inspiring ideas to have fun with your family. Normally such paper towels are two-ply. Type III: ISO 14025 By 2016, some companies had initiated public awareness campaigns instructing residents not to flush discarded wipes. The tissue paper manufacturing process only varies slightly from that of other papers.

Well known amongst these are claims of "100% recycled" in relation to tissue/paper. Neukld dn osobn daje. At the end of process toilet paper is bleached and scented. The toilet paper manufacturing process starts by creating a paper. It's usually sold as a roll of perforated paper that's swaddled around a cardboard core and kept in a dispenser next to the toilet. The tissue is then transferred on to a massive heated roller called a Yankee. Most toilet paper sold in the commercial world nowadays is designed to degrade in septic tanks, so it is recyclable. In 2019, the NRDC and Stand.earth released a report grading various brands of toilet paper, paper towels, and facial tissue; the report criticized major brands for lacking recycled material.[31]. The data supplied by the manufacturing companies are also independently reviewed. There are numerous methods to utilize toilet paper due to its widespread availability in homes. Tissue paper is a lightweight paper, or a crepe paper, which can be made from recycled paper pulp among other materials. The manufacturing steps include preparation, deconstruction, digestions, cleaning, pre-production pressing, production, rolling for roll formation, and finally cutting. The crinkle (crping) is controlled by the strength of the adhesive, geometry of the doctor blade, speed difference between the Yankee and final section of the paper machine and paper pulp characteristics.[2]. Market Study. Cookies slou k uloen souhlasu uivatele s cookies v kategorii Nezbytn. The paper is scraped off with metal blades and wound on jumbo reels. The difference between virgin paper goods (produced from chopped wood) and those made from recycled toilet paper is the most significant difference in making toilet paper. They are passionate about turning your everyday moments into memories and bringing you inspiring ideas to have fun with your family. Normally such paper towels are two-ply. Type III: ISO 14025 By 2016, some companies had initiated public awareness campaigns instructing residents not to flush discarded wipes. The tissue paper manufacturing process only varies slightly from that of other papers.