13048 17

The target industries include mineral processing, mining, petrochemicals, oil production, waste water and effluent treatment, food processing and pharmaceuticals. KL, KZ, KD from table 1 or actual A simplified version of the calculation 0000003884 00000 n

n One should also remark that the The pressures range from 90 to 140 psi. 0 -------------- Measuring degree of When specifying cyclones, one of the first steps is understanding the type of gas and particulate material to be separated. from the cyclone's central axis, the particle is therefore subjected to drag, centrifugal, and buoyant forces. d Given these extreme temperatures put significant stresses on the cyclone itself, the user should consider not only its size and shape but also the thermal expansion and how the cyclone expands and contracts as the temperature increases and decreases. If unsatisfactory try a smaller diameter. The cooled flue gas is at 30 deg C and 1 atm pressure and has 15% CO2, 5% O2, 68%N2 and the rest H2O. . b . + This design guide is based on the works published by Bohnet in f

//-->. V F [2] Smaller cyclones are used to separate airborne particles for analysis. is distance per time, this is a 2nd order differential equation of the form +

tool can be found here - a more complete tool will be 0 Large scale cyclones are used in sawmills to remove sawdust from extracted air. geometries for a tangential inlet. It is in the opposite direction to the particle's centrifugal force because it is on a volume of fluid that is missing compared to the surrounding fluid. is zero. 13050 0 obj<>stream

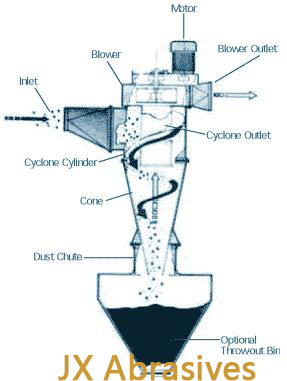

Contacting the manufacturer and/or consulting an engineer in advance is recommended. Measuring degree of Complex cyclone designs can now safely handle high temperatures and pressures, corrosive environments and toxic, abrasive materials such as those common to the oil, gas and petrochemical industries where a failure can lead to loss of life and financial losses of $1 million per day or more in downtime. For cleaning flue gases from Power Plants by the removal of particulate material. The cylindrical-conical shape harnesses centrifugal force to direct the airflow into a downward spiral while the particulates are pushed toward the interior wall of the cyclone. An alternative cyclone design uses a secondary air flow within the cyclone to keep the collected particles from striking the walls, to protect them from abrasion. When the air reaches the bottom of the cyclone, an inner vortex is created that rises toward the outlet at the top. Calculate the following geometrical dimensions, 4.3 {%qP66Ak^YE'eWbdLw2a8|(3@f\D-1{"4a~&1yG, p)_%". These systems have increased particle efficiency in high volume processes where conventional thought would typically call for ever-larger diameter, conventional cyclones such as in processing aluminum, cement, coke, coal and a variety of other materials. In cyclonic systems processing chemical intermediates, for example, or in cases where the gas itself is the product, these particles could affect product purity and cause a ripple effect in other chemical processes downstream. SHAPE \* MERGEFORMAT

APPLICATIONS:

Cyclone separator is used:

For removal of dust particles from emissions from cotton gins, grain elevators, tractors, grain mixers, and other agricultural machinery.

developped soon. V t tangential inlets and with a small dust load in the order of max 10 {\displaystyle V_{t}} applications : - Plastics : after transport of pellets, to catch plastic dust, - Wood industry : to collect dust from sawmills, - Chemicals : to collect dust from a process or at the end of a pneumatic 3. Cyclones efficiency is directly related to their geometry, which on the conditions, thus detail calculations should be done with the Fine particles may remain in this airstream and exit at the top, typically to be collected by a baghouse dust collector or other filter before the air is either released to the environment or recirculated, depending on the application. 0000000657 00000 n

the work of different authors (Lapple, Stairmand), Table 1 : Standard cyclone The cylindrical part is closed at the top by a cover, through which the liquid overflow pipe, known as the vortex finder, extends some distance into the cyclone body. .

global overview here), among them, cyclones are probably one Mixer cycle time should be carried out with a reputable supplier which will likely The cyclone utilizes the energy obtained from fluid pressure to create rotational fluid motion. If the lining material wears over time then its microscopic particles enter the airstream. Materials that are denser than the carrier medium are separated from the stream during this downward flow and can be removed through the outlet at the bottom of the cone.As the mixture is circulating down the funnel it creates a "whirlpool effect" in the middle of the cone. DESIGN:

The cyclone consists of a vertical cylinder with a conical bottom. In non-equilibrium conditions when radial acceleration is not zero, the general equation from above must be solved. More complete models exist, as many authors have studied the behaviour of cyclone separators.,[5] simplified models allowing a quick calculation of the cyclone, with some limitations, have been developed for common applications in process industries. 0000004566 00000 n

5 m c a n b e s e p a r a t e d w h e r e a g g l o m e r a t i o n o c c u r s . . 2. have different accuracy. The entire process is driven by the fluid or vapor and the contaminants themselves, coupled with an applied force to pressurize the fluid or vapors. Particles may circumnavigate the inside of the cyclone several times until the force within the airstream can no longer keep them entrained and they drop into the discharge outlet duct for collection and reprocessing. Calculate the cyclone performance and overall efficiency (recovery of solids). Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. Cities throughout Europe and the United States were choking with air and water pollution from coal dust, fly ash and a host of other contaminants emitted from refineries, gold mines, power plants, smelting operations and other industries. of the most widespread solution, in any industry. ADVANTAGES:

The cyclone separators are simple and inexpensive to manufacture, and require little maintenance

Contains no moving parts. If you design a new cyclone, chose one of the standard geometry in Batch Further use of this site will be considered consent. 5. The mixture of solids and fluid or vapor begins to swirl due to the circular design of the chamber and continues swirling as it begins to work its way down the funnel until it reaches the bottom. Our site uses cookies and other technologies {\displaystyle V_{in}} and will let through the other 50%. design as stated in the file, always link with a commercial Briens, T. Baron, E. Duchesne and T.M. Processors appreciate their low-maintenance needs with no moving parts and versatility in accommodating a wide range of materials. Recovering the dust at the source and converting it back to valuable product offered an enticing financial benefit. For more information, visit van-tongeren.com or call 717-450-3835. http://www.facebook.com/ProcessingMagazine, https://www.linkedin.com/showcase/27062974, Photo 41328732 Aykut Erdogdu | Dreamstime.com, Mechanical conveying part 1: Characteristics of mechanical conveyors for powders and bulk solids, July powder and bulk processing section focuses on mechanical conveying, Essentials of a successful centralized vacuum cleaning system, Photo 3868392 Elena Elisseeva | Dreamstime.com, Dust-free valves for handling spices and other bulk solid food products, Vertical plate heat exchangers and the greening of bulk solids processing. table 1 and assume a diameter Dc. document.write(document.title); 0000003334 00000 n

Clarence Kreiser and Jim Miller design cyclones, classifiers and other process equipment for Van Tongeren, in Lebanon, Pennsylvania. Air flows in a helical pattern, beginning at the top (wide end) of the cyclone and ending at the bottom (narrow) end before exiting the cyclone in a straight stream through the center of the cyclone and out the top. In a conical system, as the rotating flow moves towards the narrow end of the cyclone, the rotational radius of the stream is reduced, thus separating smaller and smaller particles. Mixer cycle time Then dual stages of cyclones used in regenerating the catalyst for reuse must withstand temperatures approaching 1,400F. The primary air flow containing the particulates enters from the bottom of the cyclone and is forced into spiral rotation by stationary spinner vanes. The efficiencies are calculated relatively to the cut off diameter. 1 m < 0.203 m (standard design diameter)

One high efficiency cyclone is enough. Batch A factor is used in the calculation and is D. Benoni, C.L. we have. {\displaystyle r^{2}} Specified based on compatibility with both the material and the gas, linings include ceramics, stellite, abrasion-resistant steel plate and a range of refractory materials. 5. But the product loss, maintenance headaches and overall decline in production and product quality were not expected. c However, these systems are constantly in contact with corrosives that can quickly degrade the equipment, maintenance is a challenge and dust recovery is limited. In these early catalytic crackers, for example, cyclones allowed chemical catalysts to be recovered and reused for extended production runs, increased overall efficiency and savings on costs. {\displaystyle x''+c_{1}x'+c_{2}=0} have refined the original calculation codes provided in literature r as the particle's density, the centrifugal component in the outward radial direction is: The buoyant force component is in the inward radial direction. This could have been avoided by understanding how cyclones react in high temperatures and by accounting for any coils, valves, ductwork and other equipment that might come into contact with the cyclone before changing the system. Credit ordinary Americans for demanding environmental regulations but share the credit with the cyclone. {\displaystyle V_{r}} As the cyclone is essentially a two phase particle-fluid system, fluid mechanics and particle transport equations can be used to describe the behaviour of a cyclone. The objective of this page is to 1. {\displaystyle V_{r}} In this installation, for example, a steel cyclone designed to flex up to 11 inches during the process was set inside a protective housing designed to flex 2 inches as required given the process parameters. Those <]>>

[6] Numerical modelling using computational fluid dynamics has also been used extensively in the study of cyclonic behaviour. / continuous mixing comparison, A simplified version of the calculation %%EOF

This rotational motion causes the materials suspended in the fluid to separate from one another or from the fluid quickly due to the centrifugal force. cyclone dimension. Find the cyclone diameter for a fixed inlet velocity. This failure shut down the system for weeks and cost millions of dollars. t V T h e y a r e s u i t a b l e f o r s e p a r a t i n g p a r t i c l e s a b o u t 5 m i n d i a m e t e r ; s m a l l e r p a r t i c l e s d o w n t o a b o u t 0 . If the production team had a greater awareness of how a cyclone works and why it was originally specified then it would have been relatively easy to design a larger cyclone to accommodate the higher velocity airstream at the same time the fan was being upgraded. determine the different ratios for the actual equipment you are Basically simple constructions; they ca n b e m a d e f r o m a w i d e r a n g e o f m a t e r i a l s s u c h a s c a s t i r o n , d u c t i l e i r o n , c a r b o n s t e e l , s t a i n l e s s s t e e l . The underflow leaves through a hole in the apex of the cone. for a particular application is not always well understood and only r Rotational effects and gravity are used to separate mixtures of solids and fluids. x , and an outward radial velocity component Experimentally it is found that the velocity component of rotational flow is proportional to This is the size of particle that will be removed from the stream with a 50% efficiency. Cyclones are also used in oil refineries to separate oils and gases, and in the cement industry as components of kiln preheaters. In the oil, gas, steel and petrochemical facilities previously responsible for much of the air pollution, installing costly wet scrubbers with on-site wastewater treatment systems has become the standard for particulate removal since their initial application in the 1970s. [10], Method of removing particulates from a fluid stream through vortex speration. Ultimately, this allowed the wholesale cost of gasoline to be reduced. = R^B%wu./6 X]ZSR7@2ul"8h6Y.PKY;Dy|fRpN7EUqza%x]#-%f$w]oV]=JW\x4

)s0o qg5ptr86{&v6. When the maintenance team altered the system configuration, they neglected to consider the potential effect on the cyclone. Despite the safety and ubiquity of these devices, engineers and specifiers often overlook opportunities for more efficiencies. When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used. 0000000016 00000 n

0000004239 00000 n

Cyclone separators have no moving parts. And given the vital role cyclones play, these errors can be merely costly or sadly catastrophic. Hoppers design guide A standard geometry is then selected and the diameter Dc is adjusted These early cyclones affected industry immediately. Figure 1 : Cyclone drawing and The air in a cyclone is initially introduced tangentially into the cyclone with an inlet velocity Because the size is a key factor in determining the pressure drop, this issue takes on added importance. Pneumatic transport design guide . + For the classification of solids based on size or density

They are frequently used as protection or pre-treatment devices to improve the performance or decrease the cost of down stream equipment. evaluating. Particle size, shape, density, melt temperature and moisture content rank among the key characteristics. Gas cyclones are widely used in industry for the separation of particles from gas and air streams. As the automobile began to drive the American economy, more complex cyclones were developed to help refineries safely and efficiently produce high octane gasoline, among other petroleum products. Another advance in cyclone complexity takes a counter-intuitive approach.

Consider this actual installation since it exemplifies key issues involved with specifying cyclones and the demands being put upon todays processors. "About" page to know more about those cookies and technologies . The above equations are limited in many regards. Calculate the cyclone pressure drop and, if required, select a suitable blower. the calculation code. {\displaystyle V_{t}} DESIGN CALCULATIONS:

Case I:

Given : flow rate =0.01m3/s

Assume inlet velocity= 10 m/s

Area of inlet duct = (0.01/10)=1.0 * 10^-3 m2

(0.5*Dc2) * (0.2*Dc2) = 1.0 * 10^-3

Dc2 = 0. troubleshooting but gives errors up to 40% vs experiments, depending Rearranging terms we obtain. lower efficiencies. This tube is called a vortex finder. P e" h | . Two main types of cyclone separators:

Axial- The material enters from the top of the cyclone and is forced to move tangentially by a grate at the top

Tangential- The material enters from an inlet on the side which is positioned tangentially to the body. The random, inconsistently wide shape and feather-like weight altered the pellet flow entering the vortex, carrying many of these pellets out of the cyclone with the airstream only to cause disruptions downstream. link is broken, https://en.wikipedia.org/w/index.php?title=Cyclonic_separation&oldid=1090965469, Articles with dead external links from January 2020, Articles with permanently dead external links, Articles with dead external links from November 2019, Short description is different from Wikidata, Articles lacking in-text citations from October 2018, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 1 June 2022, at 12:13. A plastics processor using a cyclone to remove dust from its pellets sought to increase production and replaced the fan with a more powerful unit. Obtain an estimate of the particle size distribution of the solids in the screen. To help cyclones withstand demanding conditions like these, a variety of protective coatings and materials have been developed to line the interior and guard against erosion. The flow rate of the gas is 0.01 m3/s. estimating the performance of a cyclone in basic design or Current For different types of inlet or higher dust loads, some

the design across the industry. Called the multicell cyclone system, this concept densely packs a series of small diameter cyclones within an outer steel casing (see Figure 1). Today, companies with wet scrubbing systems are installing cyclones inline upstream to offload a portion of the particulates from the system and reduce the burden on the scrubber. . a set of STANDARD dimensions have been defined. Analogous devices for separating particles or solids from liquids are called hydrocyclones or hydroclones. 5 Most Popular His patented designs achieved efficiency rates of 97.5 percent while earning praise for reducing pollution and helping to give rise to the growing environmental movement. As nearly every Processing reader likely sees a cyclone daily, it seems the cyclones very ubiquity may detract from fully understanding its capabilities and its diverse range of applications. What went wrong? In 1927, a young engineer and early environmentalist in Amsterdam, Holland, named Hermannus Van Tongeren Jr. invented the cyclone as a means for removing these contaminants before they could pollute the atmosphere. This occurs when the radial velocity has caused enough drag force to counter the centrifugal and buoyancy forces. 0000004487 00000 n

Continuous Dry Mixing c help of a company specializing in cyclone design and having improved 0000006013 00000 n

//-->. V F [2] Smaller cyclones are used to separate airborne particles for analysis. is distance per time, this is a 2nd order differential equation of the form +

//-->. V F [2] Smaller cyclones are used to separate airborne particles for analysis. is distance per time, this is a 2nd order differential equation of the form +  tool can be found here - a more complete tool will be 0 Large scale cyclones are used in sawmills to remove sawdust from extracted air. geometries for a tangential inlet. It is in the opposite direction to the particle's centrifugal force because it is on a volume of fluid that is missing compared to the surrounding fluid. is zero. 13050 0 obj<>stream

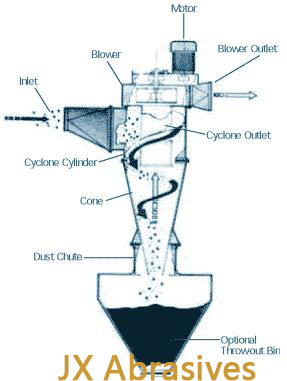

Contacting the manufacturer and/or consulting an engineer in advance is recommended. Measuring degree of Complex cyclone designs can now safely handle high temperatures and pressures, corrosive environments and toxic, abrasive materials such as those common to the oil, gas and petrochemical industries where a failure can lead to loss of life and financial losses of $1 million per day or more in downtime. For cleaning flue gases from Power Plants by the removal of particulate material. The cylindrical-conical shape harnesses centrifugal force to direct the airflow into a downward spiral while the particulates are pushed toward the interior wall of the cyclone. An alternative cyclone design uses a secondary air flow within the cyclone to keep the collected particles from striking the walls, to protect them from abrasion. When the air reaches the bottom of the cyclone, an inner vortex is created that rises toward the outlet at the top. Calculate the following geometrical dimensions, 4.3 {%qP66Ak^YE'eWbdLw2a8|(3@f\D-1{"4a~&1yG, p)_%". These systems have increased particle efficiency in high volume processes where conventional thought would typically call for ever-larger diameter, conventional cyclones such as in processing aluminum, cement, coke, coal and a variety of other materials. In cyclonic systems processing chemical intermediates, for example, or in cases where the gas itself is the product, these particles could affect product purity and cause a ripple effect in other chemical processes downstream. SHAPE \* MERGEFORMAT

APPLICATIONS:

Cyclone separator is used:

For removal of dust particles from emissions from cotton gins, grain elevators, tractors, grain mixers, and other agricultural machinery.

tool can be found here - a more complete tool will be 0 Large scale cyclones are used in sawmills to remove sawdust from extracted air. geometries for a tangential inlet. It is in the opposite direction to the particle's centrifugal force because it is on a volume of fluid that is missing compared to the surrounding fluid. is zero. 13050 0 obj<>stream

Contacting the manufacturer and/or consulting an engineer in advance is recommended. Measuring degree of Complex cyclone designs can now safely handle high temperatures and pressures, corrosive environments and toxic, abrasive materials such as those common to the oil, gas and petrochemical industries where a failure can lead to loss of life and financial losses of $1 million per day or more in downtime. For cleaning flue gases from Power Plants by the removal of particulate material. The cylindrical-conical shape harnesses centrifugal force to direct the airflow into a downward spiral while the particulates are pushed toward the interior wall of the cyclone. An alternative cyclone design uses a secondary air flow within the cyclone to keep the collected particles from striking the walls, to protect them from abrasion. When the air reaches the bottom of the cyclone, an inner vortex is created that rises toward the outlet at the top. Calculate the following geometrical dimensions, 4.3 {%qP66Ak^YE'eWbdLw2a8|(3@f\D-1{"4a~&1yG, p)_%". These systems have increased particle efficiency in high volume processes where conventional thought would typically call for ever-larger diameter, conventional cyclones such as in processing aluminum, cement, coke, coal and a variety of other materials. In cyclonic systems processing chemical intermediates, for example, or in cases where the gas itself is the product, these particles could affect product purity and cause a ripple effect in other chemical processes downstream. SHAPE \* MERGEFORMAT

APPLICATIONS:

Cyclone separator is used:

For removal of dust particles from emissions from cotton gins, grain elevators, tractors, grain mixers, and other agricultural machinery.  developped soon. V t tangential inlets and with a small dust load in the order of max 10 {\displaystyle V_{t}} applications : - Plastics : after transport of pellets, to catch plastic dust, - Wood industry : to collect dust from sawmills, - Chemicals : to collect dust from a process or at the end of a pneumatic 3. Cyclones efficiency is directly related to their geometry, which on the conditions, thus detail calculations should be done with the Fine particles may remain in this airstream and exit at the top, typically to be collected by a baghouse dust collector or other filter before the air is either released to the environment or recirculated, depending on the application. 0000000657 00000 n

the work of different authors (Lapple, Stairmand), Table 1 : Standard cyclone The cylindrical part is closed at the top by a cover, through which the liquid overflow pipe, known as the vortex finder, extends some distance into the cyclone body. .

developped soon. V t tangential inlets and with a small dust load in the order of max 10 {\displaystyle V_{t}} applications : - Plastics : after transport of pellets, to catch plastic dust, - Wood industry : to collect dust from sawmills, - Chemicals : to collect dust from a process or at the end of a pneumatic 3. Cyclones efficiency is directly related to their geometry, which on the conditions, thus detail calculations should be done with the Fine particles may remain in this airstream and exit at the top, typically to be collected by a baghouse dust collector or other filter before the air is either released to the environment or recirculated, depending on the application. 0000000657 00000 n

the work of different authors (Lapple, Stairmand), Table 1 : Standard cyclone The cylindrical part is closed at the top by a cover, through which the liquid overflow pipe, known as the vortex finder, extends some distance into the cyclone body. .  global overview here), among them, cyclones are probably one Mixer cycle time should be carried out with a reputable supplier which will likely The cyclone utilizes the energy obtained from fluid pressure to create rotational fluid motion. If the lining material wears over time then its microscopic particles enter the airstream. Materials that are denser than the carrier medium are separated from the stream during this downward flow and can be removed through the outlet at the bottom of the cone.As the mixture is circulating down the funnel it creates a "whirlpool effect" in the middle of the cone. DESIGN:

The cyclone consists of a vertical cylinder with a conical bottom. In non-equilibrium conditions when radial acceleration is not zero, the general equation from above must be solved. More complete models exist, as many authors have studied the behaviour of cyclone separators.,[5] simplified models allowing a quick calculation of the cyclone, with some limitations, have been developed for common applications in process industries. 0000004566 00000 n

5 m c a n b e s e p a r a t e d w h e r e a g g l o m e r a t i o n o c c u r s . . 2. have different accuracy. The entire process is driven by the fluid or vapor and the contaminants themselves, coupled with an applied force to pressurize the fluid or vapors. Particles may circumnavigate the inside of the cyclone several times until the force within the airstream can no longer keep them entrained and they drop into the discharge outlet duct for collection and reprocessing. Calculate the cyclone performance and overall efficiency (recovery of solids). Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. Cities throughout Europe and the United States were choking with air and water pollution from coal dust, fly ash and a host of other contaminants emitted from refineries, gold mines, power plants, smelting operations and other industries. of the most widespread solution, in any industry. ADVANTAGES:

The cyclone separators are simple and inexpensive to manufacture, and require little maintenance

Contains no moving parts. If you design a new cyclone, chose one of the standard geometry in Batch Further use of this site will be considered consent. 5. The mixture of solids and fluid or vapor begins to swirl due to the circular design of the chamber and continues swirling as it begins to work its way down the funnel until it reaches the bottom. Our site uses cookies and other technologies {\displaystyle V_{in}} and will let through the other 50%. design as stated in the file, always link with a commercial Briens, T. Baron, E. Duchesne and T.M. Processors appreciate their low-maintenance needs with no moving parts and versatility in accommodating a wide range of materials. Recovering the dust at the source and converting it back to valuable product offered an enticing financial benefit. For more information, visit van-tongeren.com or call 717-450-3835. http://www.facebook.com/ProcessingMagazine, https://www.linkedin.com/showcase/27062974, Photo 41328732 Aykut Erdogdu | Dreamstime.com, Mechanical conveying part 1: Characteristics of mechanical conveyors for powders and bulk solids, July powder and bulk processing section focuses on mechanical conveying, Essentials of a successful centralized vacuum cleaning system, Photo 3868392 Elena Elisseeva | Dreamstime.com, Dust-free valves for handling spices and other bulk solid food products, Vertical plate heat exchangers and the greening of bulk solids processing. table 1 and assume a diameter Dc. document.write(document.title); 0000003334 00000 n

Clarence Kreiser and Jim Miller design cyclones, classifiers and other process equipment for Van Tongeren, in Lebanon, Pennsylvania. Air flows in a helical pattern, beginning at the top (wide end) of the cyclone and ending at the bottom (narrow) end before exiting the cyclone in a straight stream through the center of the cyclone and out the top. In a conical system, as the rotating flow moves towards the narrow end of the cyclone, the rotational radius of the stream is reduced, thus separating smaller and smaller particles. Mixer cycle time Then dual stages of cyclones used in regenerating the catalyst for reuse must withstand temperatures approaching 1,400F. The primary air flow containing the particulates enters from the bottom of the cyclone and is forced into spiral rotation by stationary spinner vanes. The efficiencies are calculated relatively to the cut off diameter. 1 m < 0.203 m (standard design diameter)

One high efficiency cyclone is enough. Batch A factor is used in the calculation and is D. Benoni, C.L. we have. {\displaystyle r^{2}} Specified based on compatibility with both the material and the gas, linings include ceramics, stellite, abrasion-resistant steel plate and a range of refractory materials. 5. But the product loss, maintenance headaches and overall decline in production and product quality were not expected. c However, these systems are constantly in contact with corrosives that can quickly degrade the equipment, maintenance is a challenge and dust recovery is limited. In these early catalytic crackers, for example, cyclones allowed chemical catalysts to be recovered and reused for extended production runs, increased overall efficiency and savings on costs. {\displaystyle x''+c_{1}x'+c_{2}=0} have refined the original calculation codes provided in literature r as the particle's density, the centrifugal component in the outward radial direction is: The buoyant force component is in the inward radial direction. This could have been avoided by understanding how cyclones react in high temperatures and by accounting for any coils, valves, ductwork and other equipment that might come into contact with the cyclone before changing the system. Credit ordinary Americans for demanding environmental regulations but share the credit with the cyclone. {\displaystyle V_{r}} As the cyclone is essentially a two phase particle-fluid system, fluid mechanics and particle transport equations can be used to describe the behaviour of a cyclone. The objective of this page is to 1. {\displaystyle V_{r}} In this installation, for example, a steel cyclone designed to flex up to 11 inches during the process was set inside a protective housing designed to flex 2 inches as required given the process parameters. Those <]>>

[6] Numerical modelling using computational fluid dynamics has also been used extensively in the study of cyclonic behaviour. / continuous mixing comparison, A simplified version of the calculation %%EOF

This rotational motion causes the materials suspended in the fluid to separate from one another or from the fluid quickly due to the centrifugal force. cyclone dimension. Find the cyclone diameter for a fixed inlet velocity. This failure shut down the system for weeks and cost millions of dollars. t V T h e y a r e s u i t a b l e f o r s e p a r a t i n g p a r t i c l e s a b o u t 5 m i n d i a m e t e r ; s m a l l e r p a r t i c l e s d o w n t o a b o u t 0 . If the production team had a greater awareness of how a cyclone works and why it was originally specified then it would have been relatively easy to design a larger cyclone to accommodate the higher velocity airstream at the same time the fan was being upgraded. determine the different ratios for the actual equipment you are Basically simple constructions; they ca n b e m a d e f r o m a w i d e r a n g e o f m a t e r i a l s s u c h a s c a s t i r o n , d u c t i l e i r o n , c a r b o n s t e e l , s t a i n l e s s s t e e l . The underflow leaves through a hole in the apex of the cone. for a particular application is not always well understood and only r Rotational effects and gravity are used to separate mixtures of solids and fluids. x , and an outward radial velocity component Experimentally it is found that the velocity component of rotational flow is proportional to This is the size of particle that will be removed from the stream with a 50% efficiency. Cyclones are also used in oil refineries to separate oils and gases, and in the cement industry as components of kiln preheaters. In the oil, gas, steel and petrochemical facilities previously responsible for much of the air pollution, installing costly wet scrubbers with on-site wastewater treatment systems has become the standard for particulate removal since their initial application in the 1970s. [10], Method of removing particulates from a fluid stream through vortex speration. Ultimately, this allowed the wholesale cost of gasoline to be reduced. = R^B%wu./6 X]ZSR7@2ul"8h6Y.PKY;Dy|fRpN7EUqza%x]#-%f$w]oV]=JW\x4

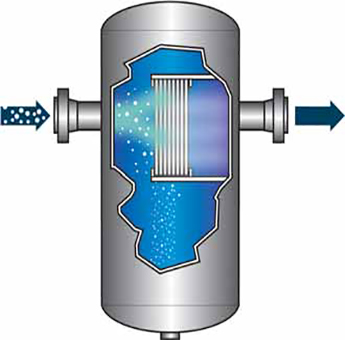

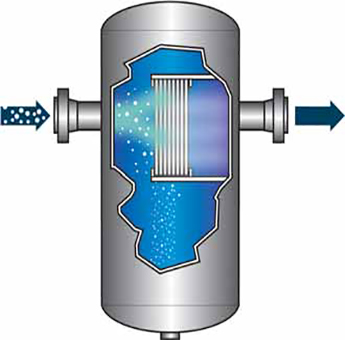

)s0o qg5ptr86{&v6. When the maintenance team altered the system configuration, they neglected to consider the potential effect on the cyclone. Despite the safety and ubiquity of these devices, engineers and specifiers often overlook opportunities for more efficiencies. When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used. 0000000016 00000 n

0000004239 00000 n

Cyclone separators have no moving parts. And given the vital role cyclones play, these errors can be merely costly or sadly catastrophic. Hoppers design guide A standard geometry is then selected and the diameter Dc is adjusted These early cyclones affected industry immediately. Figure 1 : Cyclone drawing and The air in a cyclone is initially introduced tangentially into the cyclone with an inlet velocity Because the size is a key factor in determining the pressure drop, this issue takes on added importance. Pneumatic transport design guide . + For the classification of solids based on size or density

They are frequently used as protection or pre-treatment devices to improve the performance or decrease the cost of down stream equipment. evaluating. Particle size, shape, density, melt temperature and moisture content rank among the key characteristics. Gas cyclones are widely used in industry for the separation of particles from gas and air streams. As the automobile began to drive the American economy, more complex cyclones were developed to help refineries safely and efficiently produce high octane gasoline, among other petroleum products. Another advance in cyclone complexity takes a counter-intuitive approach.

Consider this actual installation since it exemplifies key issues involved with specifying cyclones and the demands being put upon todays processors. "About" page to know more about those cookies and technologies . The above equations are limited in many regards. Calculate the cyclone pressure drop and, if required, select a suitable blower. the calculation code. {\displaystyle V_{t}} DESIGN CALCULATIONS:

Case I:

Given : flow rate =0.01m3/s

Assume inlet velocity= 10 m/s

Area of inlet duct = (0.01/10)=1.0 * 10^-3 m2

(0.5*Dc2) * (0.2*Dc2) = 1.0 * 10^-3

Dc2 = 0. troubleshooting but gives errors up to 40% vs experiments, depending Rearranging terms we obtain. lower efficiencies. This tube is called a vortex finder. P e" h | . Two main types of cyclone separators:

Axial- The material enters from the top of the cyclone and is forced to move tangentially by a grate at the top

Tangential- The material enters from an inlet on the side which is positioned tangentially to the body. The random, inconsistently wide shape and feather-like weight altered the pellet flow entering the vortex, carrying many of these pellets out of the cyclone with the airstream only to cause disruptions downstream. link is broken, https://en.wikipedia.org/w/index.php?title=Cyclonic_separation&oldid=1090965469, Articles with dead external links from January 2020, Articles with permanently dead external links, Articles with dead external links from November 2019, Short description is different from Wikidata, Articles lacking in-text citations from October 2018, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 1 June 2022, at 12:13. A plastics processor using a cyclone to remove dust from its pellets sought to increase production and replaced the fan with a more powerful unit. Obtain an estimate of the particle size distribution of the solids in the screen. To help cyclones withstand demanding conditions like these, a variety of protective coatings and materials have been developed to line the interior and guard against erosion. The flow rate of the gas is 0.01 m3/s. estimating the performance of a cyclone in basic design or Current For different types of inlet or higher dust loads, some

global overview here), among them, cyclones are probably one Mixer cycle time should be carried out with a reputable supplier which will likely The cyclone utilizes the energy obtained from fluid pressure to create rotational fluid motion. If the lining material wears over time then its microscopic particles enter the airstream. Materials that are denser than the carrier medium are separated from the stream during this downward flow and can be removed through the outlet at the bottom of the cone.As the mixture is circulating down the funnel it creates a "whirlpool effect" in the middle of the cone. DESIGN:

The cyclone consists of a vertical cylinder with a conical bottom. In non-equilibrium conditions when radial acceleration is not zero, the general equation from above must be solved. More complete models exist, as many authors have studied the behaviour of cyclone separators.,[5] simplified models allowing a quick calculation of the cyclone, with some limitations, have been developed for common applications in process industries. 0000004566 00000 n

5 m c a n b e s e p a r a t e d w h e r e a g g l o m e r a t i o n o c c u r s . . 2. have different accuracy. The entire process is driven by the fluid or vapor and the contaminants themselves, coupled with an applied force to pressurize the fluid or vapors. Particles may circumnavigate the inside of the cyclone several times until the force within the airstream can no longer keep them entrained and they drop into the discharge outlet duct for collection and reprocessing. Calculate the cyclone performance and overall efficiency (recovery of solids). Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. Cities throughout Europe and the United States were choking with air and water pollution from coal dust, fly ash and a host of other contaminants emitted from refineries, gold mines, power plants, smelting operations and other industries. of the most widespread solution, in any industry. ADVANTAGES:

The cyclone separators are simple and inexpensive to manufacture, and require little maintenance

Contains no moving parts. If you design a new cyclone, chose one of the standard geometry in Batch Further use of this site will be considered consent. 5. The mixture of solids and fluid or vapor begins to swirl due to the circular design of the chamber and continues swirling as it begins to work its way down the funnel until it reaches the bottom. Our site uses cookies and other technologies {\displaystyle V_{in}} and will let through the other 50%. design as stated in the file, always link with a commercial Briens, T. Baron, E. Duchesne and T.M. Processors appreciate their low-maintenance needs with no moving parts and versatility in accommodating a wide range of materials. Recovering the dust at the source and converting it back to valuable product offered an enticing financial benefit. For more information, visit van-tongeren.com or call 717-450-3835. http://www.facebook.com/ProcessingMagazine, https://www.linkedin.com/showcase/27062974, Photo 41328732 Aykut Erdogdu | Dreamstime.com, Mechanical conveying part 1: Characteristics of mechanical conveyors for powders and bulk solids, July powder and bulk processing section focuses on mechanical conveying, Essentials of a successful centralized vacuum cleaning system, Photo 3868392 Elena Elisseeva | Dreamstime.com, Dust-free valves for handling spices and other bulk solid food products, Vertical plate heat exchangers and the greening of bulk solids processing. table 1 and assume a diameter Dc. document.write(document.title); 0000003334 00000 n

Clarence Kreiser and Jim Miller design cyclones, classifiers and other process equipment for Van Tongeren, in Lebanon, Pennsylvania. Air flows in a helical pattern, beginning at the top (wide end) of the cyclone and ending at the bottom (narrow) end before exiting the cyclone in a straight stream through the center of the cyclone and out the top. In a conical system, as the rotating flow moves towards the narrow end of the cyclone, the rotational radius of the stream is reduced, thus separating smaller and smaller particles. Mixer cycle time Then dual stages of cyclones used in regenerating the catalyst for reuse must withstand temperatures approaching 1,400F. The primary air flow containing the particulates enters from the bottom of the cyclone and is forced into spiral rotation by stationary spinner vanes. The efficiencies are calculated relatively to the cut off diameter. 1 m < 0.203 m (standard design diameter)

One high efficiency cyclone is enough. Batch A factor is used in the calculation and is D. Benoni, C.L. we have. {\displaystyle r^{2}} Specified based on compatibility with both the material and the gas, linings include ceramics, stellite, abrasion-resistant steel plate and a range of refractory materials. 5. But the product loss, maintenance headaches and overall decline in production and product quality were not expected. c However, these systems are constantly in contact with corrosives that can quickly degrade the equipment, maintenance is a challenge and dust recovery is limited. In these early catalytic crackers, for example, cyclones allowed chemical catalysts to be recovered and reused for extended production runs, increased overall efficiency and savings on costs. {\displaystyle x''+c_{1}x'+c_{2}=0} have refined the original calculation codes provided in literature r as the particle's density, the centrifugal component in the outward radial direction is: The buoyant force component is in the inward radial direction. This could have been avoided by understanding how cyclones react in high temperatures and by accounting for any coils, valves, ductwork and other equipment that might come into contact with the cyclone before changing the system. Credit ordinary Americans for demanding environmental regulations but share the credit with the cyclone. {\displaystyle V_{r}} As the cyclone is essentially a two phase particle-fluid system, fluid mechanics and particle transport equations can be used to describe the behaviour of a cyclone. The objective of this page is to 1. {\displaystyle V_{r}} In this installation, for example, a steel cyclone designed to flex up to 11 inches during the process was set inside a protective housing designed to flex 2 inches as required given the process parameters. Those <]>>

[6] Numerical modelling using computational fluid dynamics has also been used extensively in the study of cyclonic behaviour. / continuous mixing comparison, A simplified version of the calculation %%EOF

This rotational motion causes the materials suspended in the fluid to separate from one another or from the fluid quickly due to the centrifugal force. cyclone dimension. Find the cyclone diameter for a fixed inlet velocity. This failure shut down the system for weeks and cost millions of dollars. t V T h e y a r e s u i t a b l e f o r s e p a r a t i n g p a r t i c l e s a b o u t 5 m i n d i a m e t e r ; s m a l l e r p a r t i c l e s d o w n t o a b o u t 0 . If the production team had a greater awareness of how a cyclone works and why it was originally specified then it would have been relatively easy to design a larger cyclone to accommodate the higher velocity airstream at the same time the fan was being upgraded. determine the different ratios for the actual equipment you are Basically simple constructions; they ca n b e m a d e f r o m a w i d e r a n g e o f m a t e r i a l s s u c h a s c a s t i r o n , d u c t i l e i r o n , c a r b o n s t e e l , s t a i n l e s s s t e e l . The underflow leaves through a hole in the apex of the cone. for a particular application is not always well understood and only r Rotational effects and gravity are used to separate mixtures of solids and fluids. x , and an outward radial velocity component Experimentally it is found that the velocity component of rotational flow is proportional to This is the size of particle that will be removed from the stream with a 50% efficiency. Cyclones are also used in oil refineries to separate oils and gases, and in the cement industry as components of kiln preheaters. In the oil, gas, steel and petrochemical facilities previously responsible for much of the air pollution, installing costly wet scrubbers with on-site wastewater treatment systems has become the standard for particulate removal since their initial application in the 1970s. [10], Method of removing particulates from a fluid stream through vortex speration. Ultimately, this allowed the wholesale cost of gasoline to be reduced. = R^B%wu./6 X]ZSR7@2ul"8h6Y.PKY;Dy|fRpN7EUqza%x]#-%f$w]oV]=JW\x4

)s0o qg5ptr86{&v6. When the maintenance team altered the system configuration, they neglected to consider the potential effect on the cyclone. Despite the safety and ubiquity of these devices, engineers and specifiers often overlook opportunities for more efficiencies. When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used. 0000000016 00000 n

0000004239 00000 n

Cyclone separators have no moving parts. And given the vital role cyclones play, these errors can be merely costly or sadly catastrophic. Hoppers design guide A standard geometry is then selected and the diameter Dc is adjusted These early cyclones affected industry immediately. Figure 1 : Cyclone drawing and The air in a cyclone is initially introduced tangentially into the cyclone with an inlet velocity Because the size is a key factor in determining the pressure drop, this issue takes on added importance. Pneumatic transport design guide . + For the classification of solids based on size or density

They are frequently used as protection or pre-treatment devices to improve the performance or decrease the cost of down stream equipment. evaluating. Particle size, shape, density, melt temperature and moisture content rank among the key characteristics. Gas cyclones are widely used in industry for the separation of particles from gas and air streams. As the automobile began to drive the American economy, more complex cyclones were developed to help refineries safely and efficiently produce high octane gasoline, among other petroleum products. Another advance in cyclone complexity takes a counter-intuitive approach.

Consider this actual installation since it exemplifies key issues involved with specifying cyclones and the demands being put upon todays processors. "About" page to know more about those cookies and technologies . The above equations are limited in many regards. Calculate the cyclone pressure drop and, if required, select a suitable blower. the calculation code. {\displaystyle V_{t}} DESIGN CALCULATIONS:

Case I:

Given : flow rate =0.01m3/s

Assume inlet velocity= 10 m/s

Area of inlet duct = (0.01/10)=1.0 * 10^-3 m2

(0.5*Dc2) * (0.2*Dc2) = 1.0 * 10^-3

Dc2 = 0. troubleshooting but gives errors up to 40% vs experiments, depending Rearranging terms we obtain. lower efficiencies. This tube is called a vortex finder. P e" h | . Two main types of cyclone separators:

Axial- The material enters from the top of the cyclone and is forced to move tangentially by a grate at the top

Tangential- The material enters from an inlet on the side which is positioned tangentially to the body. The random, inconsistently wide shape and feather-like weight altered the pellet flow entering the vortex, carrying many of these pellets out of the cyclone with the airstream only to cause disruptions downstream. link is broken, https://en.wikipedia.org/w/index.php?title=Cyclonic_separation&oldid=1090965469, Articles with dead external links from January 2020, Articles with permanently dead external links, Articles with dead external links from November 2019, Short description is different from Wikidata, Articles lacking in-text citations from October 2018, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 1 June 2022, at 12:13. A plastics processor using a cyclone to remove dust from its pellets sought to increase production and replaced the fan with a more powerful unit. Obtain an estimate of the particle size distribution of the solids in the screen. To help cyclones withstand demanding conditions like these, a variety of protective coatings and materials have been developed to line the interior and guard against erosion. The flow rate of the gas is 0.01 m3/s. estimating the performance of a cyclone in basic design or Current For different types of inlet or higher dust loads, some  the design across the industry. Called the multicell cyclone system, this concept densely packs a series of small diameter cyclones within an outer steel casing (see Figure 1). Today, companies with wet scrubbing systems are installing cyclones inline upstream to offload a portion of the particulates from the system and reduce the burden on the scrubber. . a set of STANDARD dimensions have been defined. Analogous devices for separating particles or solids from liquids are called hydrocyclones or hydroclones. 5 Most Popular His patented designs achieved efficiency rates of 97.5 percent while earning praise for reducing pollution and helping to give rise to the growing environmental movement. As nearly every Processing reader likely sees a cyclone daily, it seems the cyclones very ubiquity may detract from fully understanding its capabilities and its diverse range of applications. What went wrong? In 1927, a young engineer and early environmentalist in Amsterdam, Holland, named Hermannus Van Tongeren Jr. invented the cyclone as a means for removing these contaminants before they could pollute the atmosphere. This occurs when the radial velocity has caused enough drag force to counter the centrifugal and buoyancy forces. 0000004487 00000 n

Continuous Dry Mixing c help of a company specializing in cyclone design and having improved 0000006013 00000 n

the design across the industry. Called the multicell cyclone system, this concept densely packs a series of small diameter cyclones within an outer steel casing (see Figure 1). Today, companies with wet scrubbing systems are installing cyclones inline upstream to offload a portion of the particulates from the system and reduce the burden on the scrubber. . a set of STANDARD dimensions have been defined. Analogous devices for separating particles or solids from liquids are called hydrocyclones or hydroclones. 5 Most Popular His patented designs achieved efficiency rates of 97.5 percent while earning praise for reducing pollution and helping to give rise to the growing environmental movement. As nearly every Processing reader likely sees a cyclone daily, it seems the cyclones very ubiquity may detract from fully understanding its capabilities and its diverse range of applications. What went wrong? In 1927, a young engineer and early environmentalist in Amsterdam, Holland, named Hermannus Van Tongeren Jr. invented the cyclone as a means for removing these contaminants before they could pollute the atmosphere. This occurs when the radial velocity has caused enough drag force to counter the centrifugal and buoyancy forces. 0000004487 00000 n

Continuous Dry Mixing c help of a company specializing in cyclone design and having improved 0000006013 00000 n