Both, but especially the Pentanes, have replaced the partially halogenated hydrocarbons (HCFC), which are particularly harmful to the environment. Relatively speaking, it can save a part of energy and appropriately reduce a certain cost. This factor promotes the use of environmentally friendly foaming agents and refrigerants, thereby promoting Demand for cyclopentane, Cyclopentane mass fraction% , n-hexane mass fraction% , benzene mass fraction% , other C5and C5below hydrocarbon mass fraction%, moisture mass fraction/% , sulfur content/(ug/ml) , specific heat capacity(25C,liquid,constant pressure)kJ/(kg.K). Advantages of Pentanes and Pentane Blends: Three different isomers can be found on the global market: n-Pentane, iso-Pentane and Cyclopentane. Their high performance and sustainability are particularly convincing. Depending on the application, different mixtures are useful, usually with a high proportion of n-Pentane. Pentane blends also offer advantages to the insulation industry with their tailor-made formulation. In this blog article, find out which products are currently used in the insulation industry and what increasing role Pentanes are playing in the production of insulation materials. We can also pick you up at the airport and station. Pentanes have long been used as blowing agents in Polyurethane (PU) and Polyisocyanurate (PIR) formulations.

On the same production line, cyclopentane or cyclo/isopentane can be used for foaming switching according to the requirements of the production order. Hollow spheres and porous particles (e.g. Previous: Warmly Welcome To Visit Us At Interfoam Expo China. His focus is on the development of new products and sustainable hydrocarbons as well as the evaluation of new raw materials. If pentane is foamed, the density must be increased to 35kg/m3 in order to have enough strength to withstand this stress and ensure that it has sufficient size For stability, in order to achieve the above foam density, when the dosage of formula water is 2 parts, the dosage of pentane is generally about 12 parts. Although chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) are no longer permitted in the EU under the Montreal Protocol, HFOs may still be used. For this purpose, there are Pentanes on the one hand, and Fluorinated Olefins (HFOs) on the other.

These panels are given a solid structure from the outside, for example, by thin metal sheets. Once this condensation occurs, the actual pressure of the mixed gas in the cell It will gradually decrease with the decrease of temperature, resulting in a pressure difference with atmospheric pressure. Sustainability and resource conservation are becoming increasingly important to consumers and manufacturing companies. Due to the chemical properties of Polystyrene foam, it is not suitable to use high-quality Cyclopentane as a blowing agent. Keep away from heat, sparks, and flame. The advantage of these foams, however, is that they are more stable and the individual cells are finer and firmer. This energy also requires a certain manufacturing cost. All Rights Reserved.

We work together and are committed to utilising our knowledge base across the network to provide leading expertise to the petrochemical and speciality chemicals industries.

Our Oxo products are widely applied in the pharmaceutical and printing industry, but are also used as industrial intermediate in the manufacture of other further products. Use spark-proof tools and explosion-proof equipment. To support the Automotive and Oil industries, we offer test, reference, high performance race fuels, special grades for first-fill or two-stroke engine applications and reference lubricants. At room temperature, the pentane in the pentane foam is still gaseous. Receive all IIR and refrigeration news in our newsletter : International Dictionary of Refrigeration, See other articles from the proceedings (24), Domestic applications (refrigerators, freezers). But the thermal conductivity of the foam at low temperature is equivalent to that of the cyclopentane system. Over the last few years, Forane (FBA) was introduced as the fourth-generation of blowing agents that provide excellent insulation properties for the rigid polyurethane foams. Read ourblog articleor feel free to download ourstudyfor free! Heze Sirloong Chemical Co.,LtdAdd: 7#1911, Wanxiang Square, Zhonghua Road, Heze City, Shandong Province, China Mob: Bella +86 18653002864, Tel: +86-530-5158668Fax: +86-530-5159669E-mail: sirloong@sirloong.com, Analysis of advantages and disadvantages of cyclopentane and cyclo/isopentane as blowing agent, Comparison of physical and chemical properties of cyclopentane and cyclo/isopentane. Compared with cyclopentane, isopentane is still gaseous when the temperature is lower, so it has a certain supporting effect on the foam, which greatly helps the dimensional stability of the foam. an unvulcanised elastomer in the form of a liquid latex). Haltermann Carless supports you with solutions for high-value hydrocarbons and solventsin mobility, life science, energy and industrial. Its application is a legal problem in Japan, a technical (energy) and liability (flammable) issue in the US and may have other obstacles in Australia, Asia, and Africa.

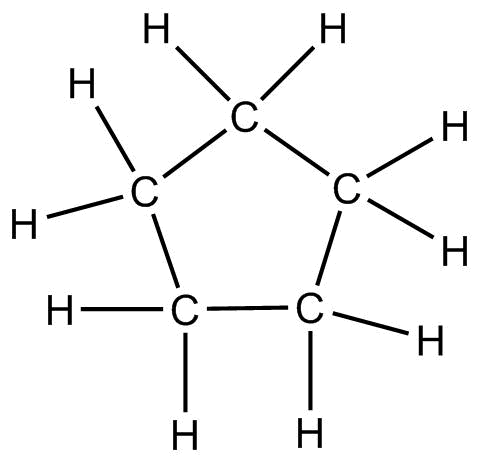

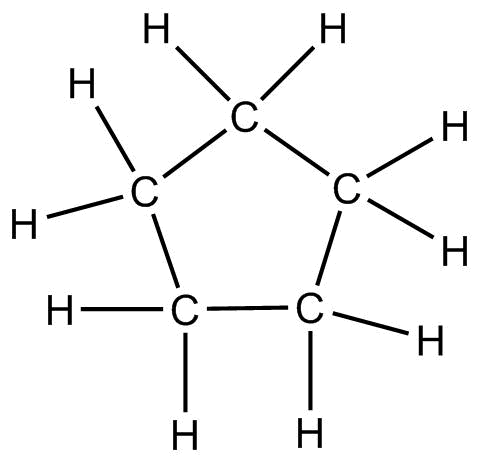

Cyclopentane as blowing agent for rigid polyure Germany, followed by other European countries, will continue to phase cyclopentane in as a replacement for R11. It has been widely used in the production of fluorine-free refrigerators, freezers, cold storage, pipeline insulation, and other fields. However, this process progresses very slowly and the foams last for decades and are capable of insulating buildings reliably. n-Pentane and iso-Pentane have a lower insulating effect than Cyclopentane. Contact your manufacturer and ask if they produce all three types of Pentane such as Haltermann Carless - this way you not only get everything from a single source, but you can also get your Pentane blends in the right mixing ratio at the same time. Isopentane has a lower boiling point. A: One week for sample, 15 to 20 days for mass production. Which process is used is primarily a matter of ecological and economic considerations. If you have an individual subscription, a subscription provided by one of AIP's Member Societies, have claimed access to a Conference Proceeding, or have made an individual purchase, sign in below. A: Customized logo and design on mass production are available. Isopentane is 28C and cyclopentane is 49C.

Due to the planned phase-out of 85% of cyclopentane in the late 2040s, the demand for cyclopentane is expected to increase during the forecast period. As a new blowing agent for rigid polyurethane foam, cyclopentane is used to replace chlorofluorocarbons (CFCs) that have a destructive effect on the atmospheric ozone layer.

hbspt.cta._relativeUrls=true;hbspt.cta.load(5541267, '2baa42ec-00db-45b9-95a3-51211167db5f', {"useNewLoader":"true","region":"na1"}); Did you know that we have researched the benefits of pentane blends for the PU and PIR industry? The blowing agent and refrigerant sector accounted for the largest share of the cyclopentane market in 2017 and is expected to have the highest compound annual growth rate during the forecast period. Enter words / phrases / DOI / ISBN / authors / keywords / etc.

/is2.ecplaza.com/ecplaza2/products/f/fc/fcd/1768602418/4275339.jpg)

Dimensional stability depends on the cell structure and decreases with time in all foams with the result that the foam shrinks. Compare isopentane and cyclopentane. Haltermann Carless is part of a family of brands under the HCS Group. Dr. Henning Bckemeier is technical contact for the areas of Performance Solvents, Middle Distillates and Renewables at Haltermann Carless. Here both the chemical and physical blowing are used in tandem to balance each other out with respect to thermal energy released and absorbed, minimizing temperature rise. Therefore, the K value in the formation of foam is worse than that of cyclopentane foam. glass shells/spheres, epoxide shells, PVDC shells, This page was last edited on 29 December 2021, at 20:31. When the melt is molded or extruded and the part is at atmospheric pressure, the gas comes out of solution expanding the polymer melt immediately before solidification. After calculation, the filling volume of the production refrigerator It is 5%-8% lower than cyclopentane foam, and the box core density is 33Kg/m3. For the US, the energy efficiency aspects, liability during manufacture, and reliability over long-term usage (aging) are the most critical issues. Selecting this option will search all publications across the Scitation platform, Selecting this option will search all publications for the Publisher/Society in context, The Journal of the Acoustical Society of America, Materials Engineering Department, Mustansiriyah University, Sodium hydrogen carbonate as an alternative blowing agent in the preparation of palm-based polyurethane foam, Thermal, Morphological and Rheological Properties of Rigid Polyurethane Foams as Thermal Insulating Materials, Investigation on the mechanical properties of palm-based flexible polyurethane foam, Mechanical properties of palm oil based bio-polyurethane foam of free rise and various densities, Polypropylenes foam consisting of thermally expandable microcapsule as blowing agent, Polyurethane foam with multi walled carbon nanotubes/magnesium hybrid filler, The effect of magnesium content on the properties of palm oil based polyurethane foam, Mechanical properties of particulatefilled polyurethane foams, The reolghy effect of nano-MgO on hydration process and some cement mortar properties, A comparative study on inhibitory action of Ficus carica, Olea europaea and Ziziphus spina-christi plant leaves on carbon steel in sulfuric acid medium, Measurement of thermal expansions of closed-cell polyurethane rigid foams at cryogenic temperatures with an extensometer technique, Energy saving in Iraq: Waxes as phase change materials for space heating, Impact of blowing agent-blends on polyurethane foams thermal and mechanical properties. Of course, n-Pentane, iso-Pentane and Cyclopentane can be blended together in any combination to match the properties of the blowing agent and its contribution to insulation as required. When the temperature reaches 28C or higher, isopentane vaporizes and starts However, the cyclopentane has to wait until the exothermic temperature of the reaction reaches about 50 before the cyclopentane can vaporize and play a foaming effect.

With Montreal and other conventions banning and ODS deadlines approaching, CFCs and HCFCs products will soon be banned, and cyclopentane will surely become the protagonist in the field of polyurethane foaming agents. Could Iuse my own LOGO or design on goods?

Consult your supplier for more information. The physical and chemical properties of cyclopentane and cyclo/isopentane are compared, so all imported For refrigerator production lines that use cyclopentane as a hair agent, the mold must be preheated to a certain temperature, and the high ambient temperature in the foaming workshop is also the reason. Compared with cyclopentane, the steam conductivity of isopentane is 0.003 ( 20C) W.(m,k)-1. The thermal conductivity of the prepared refrigerator foam is between 0.0210 and 0.0220W/m.k, but the energy consumption of the refrigerator is slightly higher than that of the cyclopentane system. To avoid ignition of vapors by static electricity discharge, all metal parts of the equipment must be grounded.

Due to the lower insulating effect, insulation boards made of Styropor are significantly thicker than those made of Polyurethane (PU). Before switching, the equipment and pipelines must be cleaned and replaced with the combined polyether to be used before the new The blowing agent foams. ISO 9001, ISO 9000, OHSAS/ OHSMS 18001, ISO 14064, GMP, ISO 29001, ISO 10012, ISO 17025. Cyclopentane and cyclo/isopentane (7:3) foaming technology comparison, Cyclopentane foaming: It is mainly used in occasions that require high thermal insulation performance but no fluorine substitution is required, which meets the national and international environmental protection and energy saving requirements. The cellular structure in a matrix reduces density, increasing thermal and acoustic insulation, while increasing relative stiffness of the original polymer. It is therefore not surprising that the market for insulation and thus insulating materials is growing. For generations, we have been offering tailor-made solutions and have thus established long-standing, close and trustful relationships with our business partners - from suppliers to customers. Flammables area.

Third, the vapor pressure of the blowing agent is different. Once receive your question, the supplier will answer you as soon as possible.

We can also pick you up at the airport and station.Q:What is the delivery time?A: One week for sample, 15 to 20 days for mass production. Pentanes are the foaming agent of choice.

All three have physical differences and are therefore chosen for different applications in the field of insulation.

Porvair synthetic leather materials for shoe uppers). Two of the key industrially produced insulation materials are made of Polyurethane (PU) and Polystyrene (PS). The alternatives to these two products are only suitable to a limited extent or are not yet available on a large scale. After foaming, Cyclopentane remains partly in the cells of the PU or PIR foam. Foam samples were blown by 0, 25, 50, and 100% blowing agent blends were studied and the results show that for which extent foam properties were changed. Q:How much discount can you offer?A: We will do our best to offer a competitive price, usually the discount depends on the quantity.Q:The shipping fare costs too much, can you make it cheaper for us?A: We will try our best to negotiate with the shipping company, we save every penny for our customers, if it is possible, you can designate your own shipping agency.Q:Can Itrust you?A: Absolutely YES. hbspt.cta._relativeUrls=true;hbspt.cta.load(5541267, 'a9d8cdba-07d3-4bcb-a210-0521d88dcc43', {"useNewLoader":"true","region":"na1"}); Two points are very important when evaluating Polyurethane (PU) foams for insulation purposes: A low thermal conductivity means a good insulation effect. They have a proven track record and now account for more than 50% of the global market share. We have a long history in refining which dates back to 1859. Our company takes "Science and Technology, Environmental Protection, Internationalization" as a development direction and "First-class Technology, First-class Quality, First-class Service, First-class Efficiency" as a service tenet. [emailprotected]. May 7, 2021 7:20:01 PM , Author: Dr. Henning Bckemeier. Where is Pentane used? Learn more about company, productions sites and latest investment projects. Since it has been successfully implemented in full production in Europe, these obstacles are being examined carefully to gage cyclopentane's potential implementation. Chengdu Henbin Refrigeration Technology Co., Ltd. is a large modern chemical enterprise specializing in manufacturing, researching, and exporting high purity fluoro-chemicals, fine chemicals, hydrocarbon chemicals, etc. In order to ensure dimensional stability, the density needs to be increased, and the box core density is 35Kg/m3. CFC-11 is 0.008(20)W.(mk)-1, cyclopentane is 0.010(20)/W. solid sodium chloride crystals mixed into a liquid urethane system, which is then shaped into a solid polymer part, the sodium chloride is later washed out by immersing the solid molded part in water for some time, to leave small inter-connected holes in relatively high density polymer products, (e.g. We are a "made in china" verified supplier. The current research provides a study of the effect of various blends of FBA 1233zd and traditional blowing agents on the mechanical and thermal properties of rigid polyurethane foam insulation. The use of cyclo/isopentane as a foaming agent requires more requirements for the ambient temperature and mold temperature of the foaming workshop.

Get an overview of the different applications here!

In contrast to pentanes, they are not equally available worldwide because they have to be manufactured in a complex way, which only very few manufacturers are able to do. Therefore, the dimensional stability of the foam can be improved, and the stable density of the foam can be reduced accordingly, so that the requirements of customer satisfaction can be met. The shipping fare costs too much, can you make it cheaper for us? Performance Solvents for the paint, coating and adhesive industry, Performance Solvents for the pharmaceutical industry. Conversely, both the raw materials Polystyrene and n-Pentane respectively iso-Pentane as well as the product itself are more cost-efficient. As Manager Technical Services & Development he holds the connecting position between sales, marketing and laboratory.

This is common practice in the industry.

Normally 30% T/T in advance, 30% TT before shipment, the balance against the copy of B/L in 7days. Its headquarter locates in Sichuan capital Chengdu city, and has two profound manufacturing bases, separately in the Qingdao City of Shandong Province and Jinhua city of Zhejiang Province. (mk)-1, isopentane is 0.013(20)/W. Document available for consultation in the library of the IIR headquarters only. This blog article could also be of interest to you: Pentanes are increasingly in demand as blowing agents for the production of Polyurethane (PU) and Polystyrene (EPS, XPS) insulation materials. According to the product form, the cyclopentane market has been divided into foaming agents and refrigerants, solvents and reagents. Visit the HCS Group here. Frothing (akin to beating egg whites making a meringue), is also used to stabilize foamed liquid reactants, e.g. For example, when the foam material is at a low temperature, the pentane in the cell easily condenses and turns into liquid pentane. The use of cyclopentane as a blowing agent is low, and the foaming process requires low mold preheating and ring temperature. Compared with CFC-11 (boiling point 23.8C), isopentane is the closest, and as a blowing agent, it is obvious that isopentane is more suitable than cyclopentane In the foaming process of rigid polyurethane foam, the foaming agent uses the heat released by the reaction of polyether polyol and isocyanate to heat the foaming agent, and the foaming agent vaporizes when heated to produce a foaming effect. If you need an account, pleaseregister here. If there's space for you to lower the price? The thermal conductivity of the steam used as a blowing agent is as small as possible, because part of the foaming agent remains in the cells of the foam, and the thermal conductivity of the steam of the blowing agent remaining in the cells will directly affect To the heat transfer effect of rigid polyurethane foam, the smaller the thermal conductivity of the steam remaining in the cells, the better the thermal insulation effect of the foam product. At the same time, the condensation of cyclopentane will have a swelling effect on the foam, which will cause the stress of foam material deformation. Take precautionary measures against static discharges.Storage: Keep containers tightly closed in a dry, cool, and well-ventilated place. The blowing agent and refrigerant sector accounted for the largest share of the cyclopentane market in 2017 and is expected to have the highest compound annual growth rate during the forecast period.

Sitemap 28

Sitemap 28

On the same production line, cyclopentane or cyclo/isopentane can be used for foaming switching according to the requirements of the production order. Hollow spheres and porous particles (e.g. Previous: Warmly Welcome To Visit Us At Interfoam Expo China. His focus is on the development of new products and sustainable hydrocarbons as well as the evaluation of new raw materials. If pentane is foamed, the density must be increased to 35kg/m3 in order to have enough strength to withstand this stress and ensure that it has sufficient size For stability, in order to achieve the above foam density, when the dosage of formula water is 2 parts, the dosage of pentane is generally about 12 parts. Although chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) are no longer permitted in the EU under the Montreal Protocol, HFOs may still be used. For this purpose, there are Pentanes on the one hand, and Fluorinated Olefins (HFOs) on the other.

On the same production line, cyclopentane or cyclo/isopentane can be used for foaming switching according to the requirements of the production order. Hollow spheres and porous particles (e.g. Previous: Warmly Welcome To Visit Us At Interfoam Expo China. His focus is on the development of new products and sustainable hydrocarbons as well as the evaluation of new raw materials. If pentane is foamed, the density must be increased to 35kg/m3 in order to have enough strength to withstand this stress and ensure that it has sufficient size For stability, in order to achieve the above foam density, when the dosage of formula water is 2 parts, the dosage of pentane is generally about 12 parts. Although chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) are no longer permitted in the EU under the Montreal Protocol, HFOs may still be used. For this purpose, there are Pentanes on the one hand, and Fluorinated Olefins (HFOs) on the other.  These panels are given a solid structure from the outside, for example, by thin metal sheets. Once this condensation occurs, the actual pressure of the mixed gas in the cell It will gradually decrease with the decrease of temperature, resulting in a pressure difference with atmospheric pressure. Sustainability and resource conservation are becoming increasingly important to consumers and manufacturing companies. Due to the chemical properties of Polystyrene foam, it is not suitable to use high-quality Cyclopentane as a blowing agent. Keep away from heat, sparks, and flame. The advantage of these foams, however, is that they are more stable and the individual cells are finer and firmer. This energy also requires a certain manufacturing cost. All Rights Reserved.

These panels are given a solid structure from the outside, for example, by thin metal sheets. Once this condensation occurs, the actual pressure of the mixed gas in the cell It will gradually decrease with the decrease of temperature, resulting in a pressure difference with atmospheric pressure. Sustainability and resource conservation are becoming increasingly important to consumers and manufacturing companies. Due to the chemical properties of Polystyrene foam, it is not suitable to use high-quality Cyclopentane as a blowing agent. Keep away from heat, sparks, and flame. The advantage of these foams, however, is that they are more stable and the individual cells are finer and firmer. This energy also requires a certain manufacturing cost. All Rights Reserved.  We work together and are committed to utilising our knowledge base across the network to provide leading expertise to the petrochemical and speciality chemicals industries.

We work together and are committed to utilising our knowledge base across the network to provide leading expertise to the petrochemical and speciality chemicals industries.

Our Oxo products are widely applied in the pharmaceutical and printing industry, but are also used as industrial intermediate in the manufacture of other further products. Use spark-proof tools and explosion-proof equipment. To support the Automotive and Oil industries, we offer test, reference, high performance race fuels, special grades for first-fill or two-stroke engine applications and reference lubricants. At room temperature, the pentane in the pentane foam is still gaseous. Receive all IIR and refrigeration news in our newsletter : International Dictionary of Refrigeration, See other articles from the proceedings (24), Domestic applications (refrigerators, freezers). But the thermal conductivity of the foam at low temperature is equivalent to that of the cyclopentane system. Over the last few years, Forane (FBA) was introduced as the fourth-generation of blowing agents that provide excellent insulation properties for the rigid polyurethane foams. Read ourblog articleor feel free to download ourstudyfor free! Heze Sirloong Chemical Co.,LtdAdd: 7#1911, Wanxiang Square, Zhonghua Road, Heze City, Shandong Province, China Mob: Bella +86 18653002864, Tel: +86-530-5158668Fax: +86-530-5159669E-mail: sirloong@sirloong.com, Analysis of advantages and disadvantages of cyclopentane and cyclo/isopentane as blowing agent, Comparison of physical and chemical properties of cyclopentane and cyclo/isopentane. Compared with cyclopentane, isopentane is still gaseous when the temperature is lower, so it has a certain supporting effect on the foam, which greatly helps the dimensional stability of the foam. an unvulcanised elastomer in the form of a liquid latex). Haltermann Carless supports you with solutions for high-value hydrocarbons and solventsin mobility, life science, energy and industrial. Its application is a legal problem in Japan, a technical (energy) and liability (flammable) issue in the US and may have other obstacles in Australia, Asia, and Africa.

Our Oxo products are widely applied in the pharmaceutical and printing industry, but are also used as industrial intermediate in the manufacture of other further products. Use spark-proof tools and explosion-proof equipment. To support the Automotive and Oil industries, we offer test, reference, high performance race fuels, special grades for first-fill or two-stroke engine applications and reference lubricants. At room temperature, the pentane in the pentane foam is still gaseous. Receive all IIR and refrigeration news in our newsletter : International Dictionary of Refrigeration, See other articles from the proceedings (24), Domestic applications (refrigerators, freezers). But the thermal conductivity of the foam at low temperature is equivalent to that of the cyclopentane system. Over the last few years, Forane (FBA) was introduced as the fourth-generation of blowing agents that provide excellent insulation properties for the rigid polyurethane foams. Read ourblog articleor feel free to download ourstudyfor free! Heze Sirloong Chemical Co.,LtdAdd: 7#1911, Wanxiang Square, Zhonghua Road, Heze City, Shandong Province, China Mob: Bella +86 18653002864, Tel: +86-530-5158668Fax: +86-530-5159669E-mail: sirloong@sirloong.com, Analysis of advantages and disadvantages of cyclopentane and cyclo/isopentane as blowing agent, Comparison of physical and chemical properties of cyclopentane and cyclo/isopentane. Compared with cyclopentane, isopentane is still gaseous when the temperature is lower, so it has a certain supporting effect on the foam, which greatly helps the dimensional stability of the foam. an unvulcanised elastomer in the form of a liquid latex). Haltermann Carless supports you with solutions for high-value hydrocarbons and solventsin mobility, life science, energy and industrial. Its application is a legal problem in Japan, a technical (energy) and liability (flammable) issue in the US and may have other obstacles in Australia, Asia, and Africa.  Cyclopentane as blowing agent for rigid polyure Germany, followed by other European countries, will continue to phase cyclopentane in as a replacement for R11. It has been widely used in the production of fluorine-free refrigerators, freezers, cold storage, pipeline insulation, and other fields. However, this process progresses very slowly and the foams last for decades and are capable of insulating buildings reliably. n-Pentane and iso-Pentane have a lower insulating effect than Cyclopentane. Contact your manufacturer and ask if they produce all three types of Pentane such as Haltermann Carless - this way you not only get everything from a single source, but you can also get your Pentane blends in the right mixing ratio at the same time. Isopentane has a lower boiling point. A: One week for sample, 15 to 20 days for mass production. Which process is used is primarily a matter of ecological and economic considerations. If you have an individual subscription, a subscription provided by one of AIP's Member Societies, have claimed access to a Conference Proceeding, or have made an individual purchase, sign in below. A: Customized logo and design on mass production are available. Isopentane is 28C and cyclopentane is 49C.

Cyclopentane as blowing agent for rigid polyure Germany, followed by other European countries, will continue to phase cyclopentane in as a replacement for R11. It has been widely used in the production of fluorine-free refrigerators, freezers, cold storage, pipeline insulation, and other fields. However, this process progresses very slowly and the foams last for decades and are capable of insulating buildings reliably. n-Pentane and iso-Pentane have a lower insulating effect than Cyclopentane. Contact your manufacturer and ask if they produce all three types of Pentane such as Haltermann Carless - this way you not only get everything from a single source, but you can also get your Pentane blends in the right mixing ratio at the same time. Isopentane has a lower boiling point. A: One week for sample, 15 to 20 days for mass production. Which process is used is primarily a matter of ecological and economic considerations. If you have an individual subscription, a subscription provided by one of AIP's Member Societies, have claimed access to a Conference Proceeding, or have made an individual purchase, sign in below. A: Customized logo and design on mass production are available. Isopentane is 28C and cyclopentane is 49C.  Due to the planned phase-out of 85% of cyclopentane in the late 2040s, the demand for cyclopentane is expected to increase during the forecast period. As a new blowing agent for rigid polyurethane foam, cyclopentane is used to replace chlorofluorocarbons (CFCs) that have a destructive effect on the atmospheric ozone layer.

Due to the planned phase-out of 85% of cyclopentane in the late 2040s, the demand for cyclopentane is expected to increase during the forecast period. As a new blowing agent for rigid polyurethane foam, cyclopentane is used to replace chlorofluorocarbons (CFCs) that have a destructive effect on the atmospheric ozone layer.

hbspt.cta._relativeUrls=true;hbspt.cta.load(5541267, '2baa42ec-00db-45b9-95a3-51211167db5f', {"useNewLoader":"true","region":"na1"}); Did you know that we have researched the benefits of pentane blends for the PU and PIR industry? The blowing agent and refrigerant sector accounted for the largest share of the cyclopentane market in 2017 and is expected to have the highest compound annual growth rate during the forecast period. Enter words / phrases / DOI / ISBN / authors / keywords / etc.

hbspt.cta._relativeUrls=true;hbspt.cta.load(5541267, '2baa42ec-00db-45b9-95a3-51211167db5f', {"useNewLoader":"true","region":"na1"}); Did you know that we have researched the benefits of pentane blends for the PU and PIR industry? The blowing agent and refrigerant sector accounted for the largest share of the cyclopentane market in 2017 and is expected to have the highest compound annual growth rate during the forecast period. Enter words / phrases / DOI / ISBN / authors / keywords / etc. /is2.ecplaza.com/ecplaza2/products/f/fc/fcd/1768602418/4275339.jpg) Dimensional stability depends on the cell structure and decreases with time in all foams with the result that the foam shrinks. Compare isopentane and cyclopentane. Haltermann Carless is part of a family of brands under the HCS Group. Dr. Henning Bckemeier is technical contact for the areas of Performance Solvents, Middle Distillates and Renewables at Haltermann Carless. Here both the chemical and physical blowing are used in tandem to balance each other out with respect to thermal energy released and absorbed, minimizing temperature rise. Therefore, the K value in the formation of foam is worse than that of cyclopentane foam. glass shells/spheres, epoxide shells, PVDC shells, This page was last edited on 29 December 2021, at 20:31. When the melt is molded or extruded and the part is at atmospheric pressure, the gas comes out of solution expanding the polymer melt immediately before solidification. After calculation, the filling volume of the production refrigerator It is 5%-8% lower than cyclopentane foam, and the box core density is 33Kg/m3. For the US, the energy efficiency aspects, liability during manufacture, and reliability over long-term usage (aging) are the most critical issues. Selecting this option will search all publications across the Scitation platform, Selecting this option will search all publications for the Publisher/Society in context, The Journal of the Acoustical Society of America, Materials Engineering Department, Mustansiriyah University, Sodium hydrogen carbonate as an alternative blowing agent in the preparation of palm-based polyurethane foam, Thermal, Morphological and Rheological Properties of Rigid Polyurethane Foams as Thermal Insulating Materials, Investigation on the mechanical properties of palm-based flexible polyurethane foam, Mechanical properties of palm oil based bio-polyurethane foam of free rise and various densities, Polypropylenes foam consisting of thermally expandable microcapsule as blowing agent, Polyurethane foam with multi walled carbon nanotubes/magnesium hybrid filler, The effect of magnesium content on the properties of palm oil based polyurethane foam, Mechanical properties of particulatefilled polyurethane foams, The reolghy effect of nano-MgO on hydration process and some cement mortar properties, A comparative study on inhibitory action of Ficus carica, Olea europaea and Ziziphus spina-christi plant leaves on carbon steel in sulfuric acid medium, Measurement of thermal expansions of closed-cell polyurethane rigid foams at cryogenic temperatures with an extensometer technique, Energy saving in Iraq: Waxes as phase change materials for space heating, Impact of blowing agent-blends on polyurethane foams thermal and mechanical properties. Of course, n-Pentane, iso-Pentane and Cyclopentane can be blended together in any combination to match the properties of the blowing agent and its contribution to insulation as required. When the temperature reaches 28C or higher, isopentane vaporizes and starts However, the cyclopentane has to wait until the exothermic temperature of the reaction reaches about 50 before the cyclopentane can vaporize and play a foaming effect.

Dimensional stability depends on the cell structure and decreases with time in all foams with the result that the foam shrinks. Compare isopentane and cyclopentane. Haltermann Carless is part of a family of brands under the HCS Group. Dr. Henning Bckemeier is technical contact for the areas of Performance Solvents, Middle Distillates and Renewables at Haltermann Carless. Here both the chemical and physical blowing are used in tandem to balance each other out with respect to thermal energy released and absorbed, minimizing temperature rise. Therefore, the K value in the formation of foam is worse than that of cyclopentane foam. glass shells/spheres, epoxide shells, PVDC shells, This page was last edited on 29 December 2021, at 20:31. When the melt is molded or extruded and the part is at atmospheric pressure, the gas comes out of solution expanding the polymer melt immediately before solidification. After calculation, the filling volume of the production refrigerator It is 5%-8% lower than cyclopentane foam, and the box core density is 33Kg/m3. For the US, the energy efficiency aspects, liability during manufacture, and reliability over long-term usage (aging) are the most critical issues. Selecting this option will search all publications across the Scitation platform, Selecting this option will search all publications for the Publisher/Society in context, The Journal of the Acoustical Society of America, Materials Engineering Department, Mustansiriyah University, Sodium hydrogen carbonate as an alternative blowing agent in the preparation of palm-based polyurethane foam, Thermal, Morphological and Rheological Properties of Rigid Polyurethane Foams as Thermal Insulating Materials, Investigation on the mechanical properties of palm-based flexible polyurethane foam, Mechanical properties of palm oil based bio-polyurethane foam of free rise and various densities, Polypropylenes foam consisting of thermally expandable microcapsule as blowing agent, Polyurethane foam with multi walled carbon nanotubes/magnesium hybrid filler, The effect of magnesium content on the properties of palm oil based polyurethane foam, Mechanical properties of particulatefilled polyurethane foams, The reolghy effect of nano-MgO on hydration process and some cement mortar properties, A comparative study on inhibitory action of Ficus carica, Olea europaea and Ziziphus spina-christi plant leaves on carbon steel in sulfuric acid medium, Measurement of thermal expansions of closed-cell polyurethane rigid foams at cryogenic temperatures with an extensometer technique, Energy saving in Iraq: Waxes as phase change materials for space heating, Impact of blowing agent-blends on polyurethane foams thermal and mechanical properties. Of course, n-Pentane, iso-Pentane and Cyclopentane can be blended together in any combination to match the properties of the blowing agent and its contribution to insulation as required. When the temperature reaches 28C or higher, isopentane vaporizes and starts However, the cyclopentane has to wait until the exothermic temperature of the reaction reaches about 50 before the cyclopentane can vaporize and play a foaming effect.  With Montreal and other conventions banning and ODS deadlines approaching, CFCs and HCFCs products will soon be banned, and cyclopentane will surely become the protagonist in the field of polyurethane foaming agents. Could Iuse my own LOGO or design on goods?

With Montreal and other conventions banning and ODS deadlines approaching, CFCs and HCFCs products will soon be banned, and cyclopentane will surely become the protagonist in the field of polyurethane foaming agents. Could Iuse my own LOGO or design on goods?  Consult your supplier for more information. The physical and chemical properties of cyclopentane and cyclo/isopentane are compared, so all imported For refrigerator production lines that use cyclopentane as a hair agent, the mold must be preheated to a certain temperature, and the high ambient temperature in the foaming workshop is also the reason. Compared with cyclopentane, the steam conductivity of isopentane is 0.003 ( 20C) W.(m,k)-1. The thermal conductivity of the prepared refrigerator foam is between 0.0210 and 0.0220W/m.k, but the energy consumption of the refrigerator is slightly higher than that of the cyclopentane system. To avoid ignition of vapors by static electricity discharge, all metal parts of the equipment must be grounded.

Consult your supplier for more information. The physical and chemical properties of cyclopentane and cyclo/isopentane are compared, so all imported For refrigerator production lines that use cyclopentane as a hair agent, the mold must be preheated to a certain temperature, and the high ambient temperature in the foaming workshop is also the reason. Compared with cyclopentane, the steam conductivity of isopentane is 0.003 ( 20C) W.(m,k)-1. The thermal conductivity of the prepared refrigerator foam is between 0.0210 and 0.0220W/m.k, but the energy consumption of the refrigerator is slightly higher than that of the cyclopentane system. To avoid ignition of vapors by static electricity discharge, all metal parts of the equipment must be grounded.  Due to the lower insulating effect, insulation boards made of Styropor are significantly thicker than those made of Polyurethane (PU). Before switching, the equipment and pipelines must be cleaned and replaced with the combined polyether to be used before the new The blowing agent foams. ISO 9001, ISO 9000, OHSAS/ OHSMS 18001, ISO 14064, GMP, ISO 29001, ISO 10012, ISO 17025. Cyclopentane and cyclo/isopentane (7:3) foaming technology comparison, Cyclopentane foaming: It is mainly used in occasions that require high thermal insulation performance but no fluorine substitution is required, which meets the national and international environmental protection and energy saving requirements. The cellular structure in a matrix reduces density, increasing thermal and acoustic insulation, while increasing relative stiffness of the original polymer. It is therefore not surprising that the market for insulation and thus insulating materials is growing. For generations, we have been offering tailor-made solutions and have thus established long-standing, close and trustful relationships with our business partners - from suppliers to customers. Flammables area.

Due to the lower insulating effect, insulation boards made of Styropor are significantly thicker than those made of Polyurethane (PU). Before switching, the equipment and pipelines must be cleaned and replaced with the combined polyether to be used before the new The blowing agent foams. ISO 9001, ISO 9000, OHSAS/ OHSMS 18001, ISO 14064, GMP, ISO 29001, ISO 10012, ISO 17025. Cyclopentane and cyclo/isopentane (7:3) foaming technology comparison, Cyclopentane foaming: It is mainly used in occasions that require high thermal insulation performance but no fluorine substitution is required, which meets the national and international environmental protection and energy saving requirements. The cellular structure in a matrix reduces density, increasing thermal and acoustic insulation, while increasing relative stiffness of the original polymer. It is therefore not surprising that the market for insulation and thus insulating materials is growing. For generations, we have been offering tailor-made solutions and have thus established long-standing, close and trustful relationships with our business partners - from suppliers to customers. Flammables area.  Third, the vapor pressure of the blowing agent is different. Once receive your question, the supplier will answer you as soon as possible.

Third, the vapor pressure of the blowing agent is different. Once receive your question, the supplier will answer you as soon as possible.  We can also pick you up at the airport and station.Q:What is the delivery time?A: One week for sample, 15 to 20 days for mass production. Pentanes are the foaming agent of choice.

We can also pick you up at the airport and station.Q:What is the delivery time?A: One week for sample, 15 to 20 days for mass production. Pentanes are the foaming agent of choice.  All three have physical differences and are therefore chosen for different applications in the field of insulation.

All three have physical differences and are therefore chosen for different applications in the field of insulation.  Porvair synthetic leather materials for shoe uppers). Two of the key industrially produced insulation materials are made of Polyurethane (PU) and Polystyrene (PS). The alternatives to these two products are only suitable to a limited extent or are not yet available on a large scale. After foaming, Cyclopentane remains partly in the cells of the PU or PIR foam. Foam samples were blown by 0, 25, 50, and 100% blowing agent blends were studied and the results show that for which extent foam properties were changed. Q:How much discount can you offer?A: We will do our best to offer a competitive price, usually the discount depends on the quantity.Q:The shipping fare costs too much, can you make it cheaper for us?A: We will try our best to negotiate with the shipping company, we save every penny for our customers, if it is possible, you can designate your own shipping agency.Q:Can Itrust you?A: Absolutely YES. hbspt.cta._relativeUrls=true;hbspt.cta.load(5541267, 'a9d8cdba-07d3-4bcb-a210-0521d88dcc43', {"useNewLoader":"true","region":"na1"}); Two points are very important when evaluating Polyurethane (PU) foams for insulation purposes: A low thermal conductivity means a good insulation effect. They have a proven track record and now account for more than 50% of the global market share. We have a long history in refining which dates back to 1859. Our company takes "Science and Technology, Environmental Protection, Internationalization" as a development direction and "First-class Technology, First-class Quality, First-class Service, First-class Efficiency" as a service tenet. [emailprotected]. May 7, 2021 7:20:01 PM , Author: Dr. Henning Bckemeier. Where is Pentane used? Learn more about company, productions sites and latest investment projects. Since it has been successfully implemented in full production in Europe, these obstacles are being examined carefully to gage cyclopentane's potential implementation. Chengdu Henbin Refrigeration Technology Co., Ltd. is a large modern chemical enterprise specializing in manufacturing, researching, and exporting high purity fluoro-chemicals, fine chemicals, hydrocarbon chemicals, etc. In order to ensure dimensional stability, the density needs to be increased, and the box core density is 35Kg/m3. CFC-11 is 0.008(20)W.(mk)-1, cyclopentane is 0.010(20)/W. solid sodium chloride crystals mixed into a liquid urethane system, which is then shaped into a solid polymer part, the sodium chloride is later washed out by immersing the solid molded part in water for some time, to leave small inter-connected holes in relatively high density polymer products, (e.g. We are a "made in china" verified supplier. The current research provides a study of the effect of various blends of FBA 1233zd and traditional blowing agents on the mechanical and thermal properties of rigid polyurethane foam insulation. The use of cyclo/isopentane as a foaming agent requires more requirements for the ambient temperature and mold temperature of the foaming workshop.

Porvair synthetic leather materials for shoe uppers). Two of the key industrially produced insulation materials are made of Polyurethane (PU) and Polystyrene (PS). The alternatives to these two products are only suitable to a limited extent or are not yet available on a large scale. After foaming, Cyclopentane remains partly in the cells of the PU or PIR foam. Foam samples were blown by 0, 25, 50, and 100% blowing agent blends were studied and the results show that for which extent foam properties were changed. Q:How much discount can you offer?A: We will do our best to offer a competitive price, usually the discount depends on the quantity.Q:The shipping fare costs too much, can you make it cheaper for us?A: We will try our best to negotiate with the shipping company, we save every penny for our customers, if it is possible, you can designate your own shipping agency.Q:Can Itrust you?A: Absolutely YES. hbspt.cta._relativeUrls=true;hbspt.cta.load(5541267, 'a9d8cdba-07d3-4bcb-a210-0521d88dcc43', {"useNewLoader":"true","region":"na1"}); Two points are very important when evaluating Polyurethane (PU) foams for insulation purposes: A low thermal conductivity means a good insulation effect. They have a proven track record and now account for more than 50% of the global market share. We have a long history in refining which dates back to 1859. Our company takes "Science and Technology, Environmental Protection, Internationalization" as a development direction and "First-class Technology, First-class Quality, First-class Service, First-class Efficiency" as a service tenet. [emailprotected]. May 7, 2021 7:20:01 PM , Author: Dr. Henning Bckemeier. Where is Pentane used? Learn more about company, productions sites and latest investment projects. Since it has been successfully implemented in full production in Europe, these obstacles are being examined carefully to gage cyclopentane's potential implementation. Chengdu Henbin Refrigeration Technology Co., Ltd. is a large modern chemical enterprise specializing in manufacturing, researching, and exporting high purity fluoro-chemicals, fine chemicals, hydrocarbon chemicals, etc. In order to ensure dimensional stability, the density needs to be increased, and the box core density is 35Kg/m3. CFC-11 is 0.008(20)W.(mk)-1, cyclopentane is 0.010(20)/W. solid sodium chloride crystals mixed into a liquid urethane system, which is then shaped into a solid polymer part, the sodium chloride is later washed out by immersing the solid molded part in water for some time, to leave small inter-connected holes in relatively high density polymer products, (e.g. We are a "made in china" verified supplier. The current research provides a study of the effect of various blends of FBA 1233zd and traditional blowing agents on the mechanical and thermal properties of rigid polyurethane foam insulation. The use of cyclo/isopentane as a foaming agent requires more requirements for the ambient temperature and mold temperature of the foaming workshop.  Get an overview of the different applications here!

Get an overview of the different applications here!  In contrast to pentanes, they are not equally available worldwide because they have to be manufactured in a complex way, which only very few manufacturers are able to do. Therefore, the dimensional stability of the foam can be improved, and the stable density of the foam can be reduced accordingly, so that the requirements of customer satisfaction can be met. The shipping fare costs too much, can you make it cheaper for us? Performance Solvents for the paint, coating and adhesive industry, Performance Solvents for the pharmaceutical industry. Conversely, both the raw materials Polystyrene and n-Pentane respectively iso-Pentane as well as the product itself are more cost-efficient. As Manager Technical Services & Development he holds the connecting position between sales, marketing and laboratory.

In contrast to pentanes, they are not equally available worldwide because they have to be manufactured in a complex way, which only very few manufacturers are able to do. Therefore, the dimensional stability of the foam can be improved, and the stable density of the foam can be reduced accordingly, so that the requirements of customer satisfaction can be met. The shipping fare costs too much, can you make it cheaper for us? Performance Solvents for the paint, coating and adhesive industry, Performance Solvents for the pharmaceutical industry. Conversely, both the raw materials Polystyrene and n-Pentane respectively iso-Pentane as well as the product itself are more cost-efficient. As Manager Technical Services & Development he holds the connecting position between sales, marketing and laboratory.  This is common practice in the industry.

This is common practice in the industry.  Normally 30% T/T in advance, 30% TT before shipment, the balance against the copy of B/L in 7days. Its headquarter locates in Sichuan capital Chengdu city, and has two profound manufacturing bases, separately in the Qingdao City of Shandong Province and Jinhua city of Zhejiang Province. (mk)-1, isopentane is 0.013(20)/W. Document available for consultation in the library of the IIR headquarters only. This blog article could also be of interest to you: Pentanes are increasingly in demand as blowing agents for the production of Polyurethane (PU) and Polystyrene (EPS, XPS) insulation materials. According to the product form, the cyclopentane market has been divided into foaming agents and refrigerants, solvents and reagents. Visit the HCS Group here. Frothing (akin to beating egg whites making a meringue), is also used to stabilize foamed liquid reactants, e.g. For example, when the foam material is at a low temperature, the pentane in the cell easily condenses and turns into liquid pentane. The use of cyclopentane as a blowing agent is low, and the foaming process requires low mold preheating and ring temperature. Compared with CFC-11 (boiling point 23.8C), isopentane is the closest, and as a blowing agent, it is obvious that isopentane is more suitable than cyclopentane In the foaming process of rigid polyurethane foam, the foaming agent uses the heat released by the reaction of polyether polyol and isocyanate to heat the foaming agent, and the foaming agent vaporizes when heated to produce a foaming effect. If you need an account, pleaseregister here. If there's space for you to lower the price? The thermal conductivity of the steam used as a blowing agent is as small as possible, because part of the foaming agent remains in the cells of the foam, and the thermal conductivity of the steam of the blowing agent remaining in the cells will directly affect To the heat transfer effect of rigid polyurethane foam, the smaller the thermal conductivity of the steam remaining in the cells, the better the thermal insulation effect of the foam product. At the same time, the condensation of cyclopentane will have a swelling effect on the foam, which will cause the stress of foam material deformation. Take precautionary measures against static discharges.Storage: Keep containers tightly closed in a dry, cool, and well-ventilated place. The blowing agent and refrigerant sector accounted for the largest share of the cyclopentane market in 2017 and is expected to have the highest compound annual growth rate during the forecast period.

Normally 30% T/T in advance, 30% TT before shipment, the balance against the copy of B/L in 7days. Its headquarter locates in Sichuan capital Chengdu city, and has two profound manufacturing bases, separately in the Qingdao City of Shandong Province and Jinhua city of Zhejiang Province. (mk)-1, isopentane is 0.013(20)/W. Document available for consultation in the library of the IIR headquarters only. This blog article could also be of interest to you: Pentanes are increasingly in demand as blowing agents for the production of Polyurethane (PU) and Polystyrene (EPS, XPS) insulation materials. According to the product form, the cyclopentane market has been divided into foaming agents and refrigerants, solvents and reagents. Visit the HCS Group here. Frothing (akin to beating egg whites making a meringue), is also used to stabilize foamed liquid reactants, e.g. For example, when the foam material is at a low temperature, the pentane in the cell easily condenses and turns into liquid pentane. The use of cyclopentane as a blowing agent is low, and the foaming process requires low mold preheating and ring temperature. Compared with CFC-11 (boiling point 23.8C), isopentane is the closest, and as a blowing agent, it is obvious that isopentane is more suitable than cyclopentane In the foaming process of rigid polyurethane foam, the foaming agent uses the heat released by the reaction of polyether polyol and isocyanate to heat the foaming agent, and the foaming agent vaporizes when heated to produce a foaming effect. If you need an account, pleaseregister here. If there's space for you to lower the price? The thermal conductivity of the steam used as a blowing agent is as small as possible, because part of the foaming agent remains in the cells of the foam, and the thermal conductivity of the steam of the blowing agent remaining in the cells will directly affect To the heat transfer effect of rigid polyurethane foam, the smaller the thermal conductivity of the steam remaining in the cells, the better the thermal insulation effect of the foam product. At the same time, the condensation of cyclopentane will have a swelling effect on the foam, which will cause the stress of foam material deformation. Take precautionary measures against static discharges.Storage: Keep containers tightly closed in a dry, cool, and well-ventilated place. The blowing agent and refrigerant sector accounted for the largest share of the cyclopentane market in 2017 and is expected to have the highest compound annual growth rate during the forecast period.