We provide guidance to our customers worldwide and offer a broad range of RA capabilities to add value for new and existing customers during their product journey.

While advances in cell reprogramming, genetic editing, and manufacturing mean affordable cell and gene therapies for a range of diseases and uses, the go-forward path will require planning around these six major issues. As a result, the cell and gene therapy market is valued at USD 4.99 billion and is expected to grow to over USD 36 billion by 2027. Your Cell and Gene Therapy Partner from Process Development to cGMP manufacturing / Asian ERG Leader Vanderbilt University Center for Technology Transfer and Commercialization 2013 - In September 2021, Cell and Gene Therapy Manufacturing & Commercialization US returned for the first time as a hybrid conference. Regulatory expertise. July 29, 2022. Gene Therapy Manufacturing and Commercialization Insights from industry experts on gene therapy manufacturing, including the latest in manufacturing methods, analytical analysis, regulatory considerations and reimbursement strategies. Beyond rare diseases: Overcome the challenges of expanding to larger patient

It is estimated that greater than 65% of cell and gene therapy manufacturing is outsourced to contract manufacturers and that gene therapy developers may need to wait up to 18 to 24 months before accessing a Contract Development and Manufacturing Organizations (CDMO) production capacity.

Topics to be discussed include: Planning for clinical and commercial manufacturing, Build a strategy for the scale up and manufacturing of for next generation off the shelf allogeneic and gene edited modalities.

Get to grips with technologies and novel platforms for efficient upstream and downstream processes.

This past year has seen remarkable progress in the growth of cell and gene therapies. The potential of personalized medicinewhere treatments are specific to an individual's geneticsexplains this exponential growth. Gene therapy is the use of a gene-modifying technology to repair, replace or correct damage in the body.

The cells will be transduced using a highly efficient ex vivo lentiviral material to encode the human PD-L1 DNA. This revolution is changing the bench, the bedside, and the boardroom.

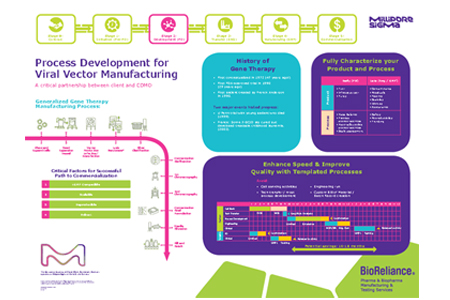

However, this method presents some limitations in largescale bioreactors: inadequate transfection protocol, reduced transfection efficiency and lower productivity. Recognizing that a lack of standard methods is the primary challenge to widespread manufacturing of cell and gene therapies, two groups are aiming to lower the barrier by bringing best practices to this branch of the life sciences industry. Recent findings from Industry Standard Research (ISR), which focuses on pharmaceutical trends, showed that the percentage of cell and gene therapy (C>) companies who outsource cell and gene therapy manufacturing is expected to drop from 44% to 22% over the next five years especially as their products move closer to commercialization. The demand for viral vectors is expected to increase, fuelled by clinical successes in gene and cell therapy. Adeno associated virus (AAV) is one of the key viral vectors used for many gene therapy applications. 6 This makes it critical for developers to

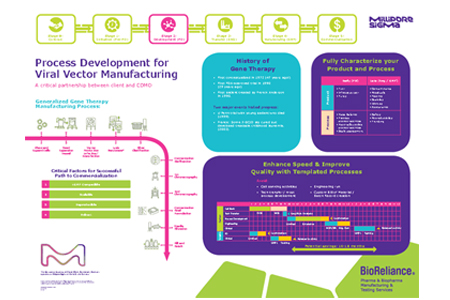

With more than 20 years of experience in manufacturing viral gene therapy products across various vector types, our team of scientists have in-depth technical expertise and a comprehensive understanding to design and develop phase-appropriate, commercially viable manufacturing processes. Cell & Gene Therapy Manufacturing & Commercialization US 2021 September 2030, 2021 Access todays leading science, technologies and partners that can accelerate your promising cell, gene and immunotherapies towards commercial success by attending the upcoming Cell & Gene Therapy Manufacturing & Commercialization US Conference & Exhibition , delivered in a The first approved gene therapy study was conducted by the National Institutes of Health (NIH) in 1989 and provided evidence for the first time that human cells could be genetically modified and returned to the patient without harm.

Co-located with BioProcess International, the event spanned across seven days, welcoming audiences in Boston and online, with tracks exploring: Cell Therapy; Gene Edited Ex Vivo Cell Therapy; In Vivo Gene Therapy Cell & Gene Therapy Manufacturing and Commercialization is a conference that covers topics such as: Cell and Gene Therapy Bioprocessing. We assembled a panel of experts in their respective fields as they relate to gene therapy manufacturing and commercialization. Viral vector process development from concept to patient.

The cell and gene therapy regulatory affairs department are experts in keeping track of the ever-changing legislation in all regions where Lonza operates.

Platform Manufacturing Approach for Adeno Associated Virus: Accelerated Time and Cost Saving.

Transient transfection of suspension cells is the most commonly usedproduction platform, as it offers significant flexibility for cell and gene therapy development. Get to grips with manufacturing and commercialisation strategies for CAR-Ts, NK cells, TCRs, TILs and iPSCs products. The AGC Biologics Milan site has a long-standing expertise in successfully developing stem cell-based gene therapies, from clinical testing up to commercialization, said Paolo Rizzardi, Chief Executive Officer of Altheia Science.

Manufacturers produce and commercialise cell and gene therapy products faster, as a result of being supported by regulatory bodies cell and gene therapy approvals and fast-track product designations Large-scale commercial production, especially viral vector manufacturing, is minimal because of insufficient flexibility, process control, speed, sustainability, and capital costs

facing gene therapy manufacturing and commercialization.

We wanted to create a guide identifying key considerations in gene therapy manufacturing for late-stage clinical development and subsequent commercialization.

Gene Therapy Manufacturing Best Practices Explored in Project A-Cell Paper.

Common Pitfalls and Lessons Learned from Cell Therapy Commercialization 10am EDT / 3pm BST / 4pm CEST Ancillary raw materials used in cell and gene therapy (CGT) manufacturing are those materials that come into contact with the drug product during the manufacturing process but are not intended to be part of the final drug product. Build a strategy for monitoring quality across your process with PAT and automated analytics.

Gene Edited Ex Vivo Cell Therapy.

involves complex logistics and the need for specialized packaging.

Sitemap 5

While advances in cell reprogramming, genetic editing, and manufacturing mean affordable cell and gene therapies for a range of diseases and uses, the go-forward path will require planning around these six major issues. As a result, the cell and gene therapy market is valued at USD 4.99 billion and is expected to grow to over USD 36 billion by 2027. Your Cell and Gene Therapy Partner from Process Development to cGMP manufacturing / Asian ERG Leader Vanderbilt University Center for Technology Transfer and Commercialization 2013 - In September 2021, Cell and Gene Therapy Manufacturing & Commercialization US returned for the first time as a hybrid conference. Regulatory expertise. July 29, 2022. Gene Therapy Manufacturing and Commercialization Insights from industry experts on gene therapy manufacturing, including the latest in manufacturing methods, analytical analysis, regulatory considerations and reimbursement strategies. Beyond rare diseases: Overcome the challenges of expanding to larger patient

While advances in cell reprogramming, genetic editing, and manufacturing mean affordable cell and gene therapies for a range of diseases and uses, the go-forward path will require planning around these six major issues. As a result, the cell and gene therapy market is valued at USD 4.99 billion and is expected to grow to over USD 36 billion by 2027. Your Cell and Gene Therapy Partner from Process Development to cGMP manufacturing / Asian ERG Leader Vanderbilt University Center for Technology Transfer and Commercialization 2013 - In September 2021, Cell and Gene Therapy Manufacturing & Commercialization US returned for the first time as a hybrid conference. Regulatory expertise. July 29, 2022. Gene Therapy Manufacturing and Commercialization Insights from industry experts on gene therapy manufacturing, including the latest in manufacturing methods, analytical analysis, regulatory considerations and reimbursement strategies. Beyond rare diseases: Overcome the challenges of expanding to larger patient  It is estimated that greater than 65% of cell and gene therapy manufacturing is outsourced to contract manufacturers and that gene therapy developers may need to wait up to 18 to 24 months before accessing a Contract Development and Manufacturing Organizations (CDMO) production capacity.

It is estimated that greater than 65% of cell and gene therapy manufacturing is outsourced to contract manufacturers and that gene therapy developers may need to wait up to 18 to 24 months before accessing a Contract Development and Manufacturing Organizations (CDMO) production capacity.

Topics to be discussed include: Planning for clinical and commercial manufacturing, Build a strategy for the scale up and manufacturing of for next generation off the shelf allogeneic and gene edited modalities.

Topics to be discussed include: Planning for clinical and commercial manufacturing, Build a strategy for the scale up and manufacturing of for next generation off the shelf allogeneic and gene edited modalities.

Get to grips with technologies and novel platforms for efficient upstream and downstream processes.

Get to grips with technologies and novel platforms for efficient upstream and downstream processes.  This past year has seen remarkable progress in the growth of cell and gene therapies. The potential of personalized medicinewhere treatments are specific to an individual's geneticsexplains this exponential growth. Gene therapy is the use of a gene-modifying technology to repair, replace or correct damage in the body.

This past year has seen remarkable progress in the growth of cell and gene therapies. The potential of personalized medicinewhere treatments are specific to an individual's geneticsexplains this exponential growth. Gene therapy is the use of a gene-modifying technology to repair, replace or correct damage in the body.

The cells will be transduced using a highly efficient ex vivo lentiviral material to encode the human PD-L1 DNA. This revolution is changing the bench, the bedside, and the boardroom.

The cells will be transduced using a highly efficient ex vivo lentiviral material to encode the human PD-L1 DNA. This revolution is changing the bench, the bedside, and the boardroom.

However, this method presents some limitations in largescale bioreactors: inadequate transfection protocol, reduced transfection efficiency and lower productivity. Recognizing that a lack of standard methods is the primary challenge to widespread manufacturing of cell and gene therapies, two groups are aiming to lower the barrier by bringing best practices to this branch of the life sciences industry. Recent findings from Industry Standard Research (ISR), which focuses on pharmaceutical trends, showed that the percentage of cell and gene therapy (C>) companies who outsource cell and gene therapy manufacturing is expected to drop from 44% to 22% over the next five years especially as their products move closer to commercialization. The demand for viral vectors is expected to increase, fuelled by clinical successes in gene and cell therapy. Adeno associated virus (AAV) is one of the key viral vectors used for many gene therapy applications. 6 This makes it critical for developers to

However, this method presents some limitations in largescale bioreactors: inadequate transfection protocol, reduced transfection efficiency and lower productivity. Recognizing that a lack of standard methods is the primary challenge to widespread manufacturing of cell and gene therapies, two groups are aiming to lower the barrier by bringing best practices to this branch of the life sciences industry. Recent findings from Industry Standard Research (ISR), which focuses on pharmaceutical trends, showed that the percentage of cell and gene therapy (C>) companies who outsource cell and gene therapy manufacturing is expected to drop from 44% to 22% over the next five years especially as their products move closer to commercialization. The demand for viral vectors is expected to increase, fuelled by clinical successes in gene and cell therapy. Adeno associated virus (AAV) is one of the key viral vectors used for many gene therapy applications. 6 This makes it critical for developers to

With more than 20 years of experience in manufacturing viral gene therapy products across various vector types, our team of scientists have in-depth technical expertise and a comprehensive understanding to design and develop phase-appropriate, commercially viable manufacturing processes. Cell & Gene Therapy Manufacturing & Commercialization US 2021 September 2030, 2021 Access todays leading science, technologies and partners that can accelerate your promising cell, gene and immunotherapies towards commercial success by attending the upcoming Cell & Gene Therapy Manufacturing & Commercialization US Conference & Exhibition , delivered in a The first approved gene therapy study was conducted by the National Institutes of Health (NIH) in 1989 and provided evidence for the first time that human cells could be genetically modified and returned to the patient without harm.

With more than 20 years of experience in manufacturing viral gene therapy products across various vector types, our team of scientists have in-depth technical expertise and a comprehensive understanding to design and develop phase-appropriate, commercially viable manufacturing processes. Cell & Gene Therapy Manufacturing & Commercialization US 2021 September 2030, 2021 Access todays leading science, technologies and partners that can accelerate your promising cell, gene and immunotherapies towards commercial success by attending the upcoming Cell & Gene Therapy Manufacturing & Commercialization US Conference & Exhibition , delivered in a The first approved gene therapy study was conducted by the National Institutes of Health (NIH) in 1989 and provided evidence for the first time that human cells could be genetically modified and returned to the patient without harm.  Co-located with BioProcess International, the event spanned across seven days, welcoming audiences in Boston and online, with tracks exploring: Cell Therapy; Gene Edited Ex Vivo Cell Therapy; In Vivo Gene Therapy Cell & Gene Therapy Manufacturing and Commercialization is a conference that covers topics such as: Cell and Gene Therapy Bioprocessing. We assembled a panel of experts in their respective fields as they relate to gene therapy manufacturing and commercialization. Viral vector process development from concept to patient.

Co-located with BioProcess International, the event spanned across seven days, welcoming audiences in Boston and online, with tracks exploring: Cell Therapy; Gene Edited Ex Vivo Cell Therapy; In Vivo Gene Therapy Cell & Gene Therapy Manufacturing and Commercialization is a conference that covers topics such as: Cell and Gene Therapy Bioprocessing. We assembled a panel of experts in their respective fields as they relate to gene therapy manufacturing and commercialization. Viral vector process development from concept to patient.  The cell and gene therapy regulatory affairs department are experts in keeping track of the ever-changing legislation in all regions where Lonza operates.

The cell and gene therapy regulatory affairs department are experts in keeping track of the ever-changing legislation in all regions where Lonza operates.  Platform Manufacturing Approach for Adeno Associated Virus: Accelerated Time and Cost Saving.

Platform Manufacturing Approach for Adeno Associated Virus: Accelerated Time and Cost Saving.  Transient transfection of suspension cells is the most commonly usedproduction platform, as it offers significant flexibility for cell and gene therapy development. Get to grips with manufacturing and commercialisation strategies for CAR-Ts, NK cells, TCRs, TILs and iPSCs products. The AGC Biologics Milan site has a long-standing expertise in successfully developing stem cell-based gene therapies, from clinical testing up to commercialization, said Paolo Rizzardi, Chief Executive Officer of Altheia Science.

Transient transfection of suspension cells is the most commonly usedproduction platform, as it offers significant flexibility for cell and gene therapy development. Get to grips with manufacturing and commercialisation strategies for CAR-Ts, NK cells, TCRs, TILs and iPSCs products. The AGC Biologics Milan site has a long-standing expertise in successfully developing stem cell-based gene therapies, from clinical testing up to commercialization, said Paolo Rizzardi, Chief Executive Officer of Altheia Science.

Manufacturers produce and commercialise cell and gene therapy products faster, as a result of being supported by regulatory bodies cell and gene therapy approvals and fast-track product designations Large-scale commercial production, especially viral vector manufacturing, is minimal because of insufficient flexibility, process control, speed, sustainability, and capital costs

Manufacturers produce and commercialise cell and gene therapy products faster, as a result of being supported by regulatory bodies cell and gene therapy approvals and fast-track product designations Large-scale commercial production, especially viral vector manufacturing, is minimal because of insufficient flexibility, process control, speed, sustainability, and capital costs

facing gene therapy manufacturing and commercialization.

facing gene therapy manufacturing and commercialization.  We wanted to create a guide identifying key considerations in gene therapy manufacturing for late-stage clinical development and subsequent commercialization.

We wanted to create a guide identifying key considerations in gene therapy manufacturing for late-stage clinical development and subsequent commercialization.

Gene Therapy Manufacturing Best Practices Explored in Project A-Cell Paper.

Gene Therapy Manufacturing Best Practices Explored in Project A-Cell Paper.

Common Pitfalls and Lessons Learned from Cell Therapy Commercialization 10am EDT / 3pm BST / 4pm CEST Ancillary raw materials used in cell and gene therapy (CGT) manufacturing are those materials that come into contact with the drug product during the manufacturing process but are not intended to be part of the final drug product. Build a strategy for monitoring quality across your process with PAT and automated analytics.

Common Pitfalls and Lessons Learned from Cell Therapy Commercialization 10am EDT / 3pm BST / 4pm CEST Ancillary raw materials used in cell and gene therapy (CGT) manufacturing are those materials that come into contact with the drug product during the manufacturing process but are not intended to be part of the final drug product. Build a strategy for monitoring quality across your process with PAT and automated analytics.  Gene Edited Ex Vivo Cell Therapy.

Gene Edited Ex Vivo Cell Therapy.  involves complex logistics and the need for specialized packaging.

involves complex logistics and the need for specialized packaging.