Unable to add item to List. Robot Tech Tutorials - simple-robotic-arm-design & industrial-robot-programming. Mid range PLC for industrial process and infrastructure. Seminars using GE PLC controllers, Allen Bradley PLC2, PLC5 family of processors. The Programmable Logic Controllers (PLC) certificate program is offered at the Penn State Berks Campus in an evening study program. PLC Controller and Software. Large, successful, growing, multi-national Custom Machine Design and, The field service engineer performs emergency repairs, warranty service; field service & engineering of electrical, Maintains the Maintenance Departments internal. During this step, any custom logic written for the PLC will execute. This class will prepare you for employment as a PLC technician/programmer. Manufacturing Engineering Technician ~ 1989 to 2001. The purpose of this logic is to make decisions based on the input data from the devices and then complete step three in the process. Learn the ins and outs of Allen Bradley RSLogix & Studio 5000 development.

You must call for the discount code! Should you want a free easy way Assess your team's PLC knowledge and skills, try these online PLC training test. Learn how to work with current (4-20ma) and voltage (0-10VDC) analog signals using two different sensors and integrating them into an Allen Bradley CompactLogix PLC running RSLogix/Studio 5000. Please try again. & Tues.)

Diverse skillsets are in demand to match the expanded roles and responsibilities of many positions. Start your sales inquiry online and an expert will connect with you. This course is designed to introduce students to the PID algorithm with emphasis on tuning the loop.

Production facilities, factories, and other industrial facilities highly value a working knowledge of PLCs. Gain actionable insights on installed equipment health to maximize uptime and boost performance. Tailor your training to the needs of your technologies, workforce, timeline, and budget.

It is very practical, it shows main features of powerflex that you would be using on real world as well as some basic examples. After spending 23 years with the Coors Brewing Co. as a Manufacturing Engineering Technician 2 years with NTT National Technology Transfer and 15 years with Clearwater Paper Corporation, Tom has provided hundreds of Programmable Logic Controller PLC training to maintenance and engineering personal. Cost: $325.

In fact, you can observe and record every step of the manufacturing process. From the completion of this course, I am ready to start programming and designing HMI's and gain confidence/experience working in this field. To further enhance the program and provide supplemental learning the Online Student Resource Center offers additional resources including alternative study content, examples, exercises, tutorial videos, student tutorial forums and the online exam center. Step-by-step projects and implementation examples help you apply all the knowledge you have acquired and test your understanding by getting your hands dirty. This product is from a small business brand. The Electrical Manager plans and leads the daily activities of the Electrical Department in the areas of Safety, Quality and Maintenance.

Whether you are an industrial designer or a maintenance person at a manufacturing facility, PLC classes can benefit you. Leverage in-person trainings our distributors host to teach Rockwell Automation capabilities. The Modicon M221 logic controller offers best-in-class performance. Control Logic Training is an independent company that develops, maintains and is solely responsible for its own training and course content, and except as expressly stated is not authorized or affiliated in any way with any product manufacturer or other training providers. Since I am a AB programmer I also liked that he showed how to connect the VFD with studio 5000 and showed how to identify VDF tags on the PLC side. Youll be exposed to various sensors and sensing techniques, process control strategies, and open architecture systems that can be leveraged to enable intelligent machining.

This is the fifth course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturings Fourth Revolution, aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal.

Ask questions and get information about the topics specific to your job. Copyright 2015new Date().getFullYear()>2010&&document.write("-"+new Date().getFullYear());, Business Industrial Network, all rights reserved. Reach out to our customer care team to receive more information, technical support, assistance with complaints and more. The power supply converts the power coming into the PLC to the required voltage level for the device. Purchase the web-based curriculum material on its own, at a cost of $370, and preview it before registering into the program. Courses are designed to align with specific job functions and focus on relevant job tasks. Room: Gaige 114 Discover more about the small businesses partnering with Amazon and Amazons commitment to empowering them. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon.

It also contains the memory chip for the device and any other integrated circuits required for its operation. Our pay-as-you-learn option gives you the ability to begin the program after paying a portion of the cost, and as you work your way through the program you will pay for your next module as you access it.

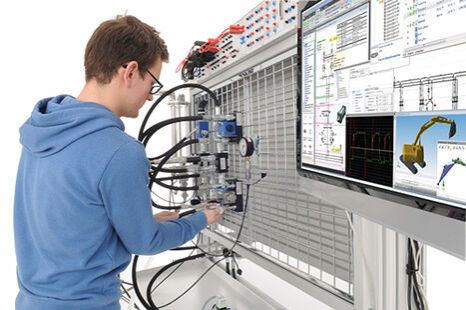

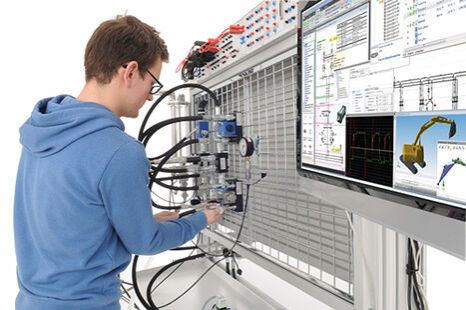

Classes are hands-on and provide students with the skills needed to become experts in automation design. Also at the bottom of each 10 section pages, will be a yellow button to for free and open access to PLC training best practices and advice relevant to that PLC learning phase / section. Because of the harsh environments where PLCs must operate, their design is rugged enough to withstand extreme temperatures and shock. Learn how to work with Point IO Distributed Hardware & How to Integrate Point IO Modules into a Control System Architecture. The PLCs collect data that routes to central computers running SCADA software. The PLCLogix 5000 simulator integrated within the program emulates the Rockwell 5000 series of PLC control software. Allen Bradley PLC (PLC/5 SLC500 and Control Logix family processors. They are most often used in a factory production environment. Frank Kaczmarcyzk earned a M.S. Essentially thePLCLogix 500simulates the PLC, ladder rung editor and all the electrical components that have, until now, been required to learn PLC programming and operation. A ControlLogix 5000 course often begins with an overview of the hardware, configuration of a PLC system and transitions into the RSLogix 5000 software. Times: TBD By being in touch with the needs of his students, he has developed a training method that his students respond well to and enjoy attending. Search topic-related frequently asked questions to find answers you need. AWS Certified Solutions Architect - Associate. At this point, the result of the custom logic makes adjustments to the output devices connected to the PLC. The core of a PLC is the CPU or central processing unit. Times: TBD Cost: $325. Thank you for giving me excellent information on digital manufacturing. A learning path to becoming a PLC expert. This step includes garbage collection, internal diagnostics, and other processes, so the next loop starts cleanly.

Our instructors are automation and controls experts actively working in the field, at some of the world's top companies, and know what its like to be in your shoes. Learn how to design modern Human Machine Interface (HMI) projects within FactoryTalk View Studio Machine Edition. Below is the recommended PLC training path, broken into 10 sections (learning phases). This process starts with an input scan. The simulation also enables program to be fully tested offline before they are entered and run in an online real-world environment removing safety concerns and possible damage to real equipment.

See also PLC training forum -discuss this site.

Digital Manufacturing & Design Technology, Salesforce Sales Development Representative, Preparing for Google Cloud Certification: Cloud Architect, Preparing for Google Cloud Certification: Cloud Data Engineer. It is a system of software and hardware that an industrial enterprise can use to control manufacturing processes both on-site and from remote locations. Dates & Times: I was able to configure and and set our new cameras and upgrade firmware on the older IS2000m . ControlLogix 5000 courses are beneficial for any individual interested in the function of PLC Programmable Logic Control systems and for technicians and companies that utilize Allen Bradley Programmable Logic Controllers in their machine or process control. I think these are THE BEST courses for beginners. What are Programmable Logic Controllers (PLC)? Education Program Associate It also includes the laboratory simulation software program and access to all of the learning resources for the 19 modules as well web-based supplemental resources, free tutorial and technical support and online testing. Initial registration is $440 (includes all learning materials, laboratory simulation softwareand Module 1) and registration for each of the remaining 18 modules is $70/module. Support Show System operator and maintenance training. The introduction to PanelView will teach students communications, creating screens, downloading, uploading, tag organization, pushbuttons, message displays, alarm messages, alarm banners, and importing user-developed objects. & Tues.) Your Importance in the Manufactured Food Industry, PLC Industry training on Allen Bradley Hardware and Software, Systems Safety Engineering, U.S. Department of Energy. This course helped me better understand the extensive functions of Cognex systems. this course has been an amazing journey, it has given me a perspective of how automation and digital manufacturing would become the ultimate form of production. The four main components of a programmable logic controller include the CPU, the power supply, the input module, and the output module. Courses are designed to align with specific job functions and focus on relevant job tasks. From e-learning and instructor-led courses to certificate programs and training workstations, we provide an array of opportunities for workers to learn, train and grow. Start learning PLC programming with unlimited courses and tutorials, 2022 SolisPLC. April 11, 12, 18, 19, 25 & 26 from 7:30PM-9:00PM (Mon. Cost: $650, Erica Kunkel To calculate the overall star rating and percentage breakdown by star, we dont use a simple average.

This course covers the fundamentals of PLC programming logic. For more details, please read our PLC Technician shares a common core of seven modules with the PLC Technician II program, including I/O System, programming terminals and peripherals, installation & maintenance of PLCs, timers, counters, sequencers, process control. The purpose of this module is to introduce the concept of Programmable Logic Controllers (PLCs) that co-ordinate the real-time control functions. issued prior to start of scheduled seminar.

The Best PLC Training is from Control Logic Training. Indicated product trademarks are the property of their respective manufacturers and are used solely to identify products for which Control Logix Training courseware is available. Easily find the nearest Schneider Electric distributor in your location. We offer training courses to help you build your teams competence, enhance safety, develop your staffs troubleshooting skills, and maximize the availability of your drives. All rights reserved. This program is divided into 19 modules; each contains text, animations, mini audio lectures, illustrations, review questions, pre-built lab projects and practice exams. Take the first step by signing up for a Control Logic Training PLC seminar at our Las Vegas training center or we can go to your company site! Dates: Tuesdays, October 25 - November 15, 2022 This course is designed to expose students to the next level of understanding with the Allen-Bradley PLCs, SLC-500 Programmable Logic Controllers and CompactLogix Controllers. This class presents a deeper understanding to project development tasks and applications. The power supply converts the current coming into the device to the voltage levels required for the CPU and other components. This simulation software which includes over250 pre-built lab projects, allows the student to develop their programming skills, writing, testing, and de-bugging PLC programs. This book with help you learn everything you need to know to get a job. Large PLC for Process applications, high availability & safety solutions. Including hardware, software, ladder logic & everything you need to be a fully competent PLC programmer. They are also programmable and modular, so technicians can tweak a manufacturing process with code and apply the same change elsewhere by just copying its code. Our instructors have over 25 years of experience, providing Rockwell Automation control system integration, PLC programming and training. As industrial control evolves, so will this site to always offer best practices in PLC training.

In addition to e-learning and hands-on courses at local training centers, some of our courses can also be conducted at your facilities. He is the lead instructor for the PLC classes at Penn State Berks for over 20 years. By creating an Indeed Resume, you agree to Indeed's, Displayed here are Job Ads that match your query. We offer both standard guides that provide detailed instructions on the most common Rockwell Automation hardware and software-related job tasks, as well as custom guides that are created to work with your plant-specific systems and application. Students will gain knowledge and practice on the methods of tuning. If you are on a budget, this can be a great way to get started on or continue your education without a huge up-front investment. Download all the tools absolutely for free, Install them on your machine, and get started in PLC Programming in RSLogix500 today! Details of each step will be unique depending on the system. This is called intelligent machining, and through this course students will receive a primer on its background, tools and related terminology.

Thank you The State University of New York and Coursera. Programmable logic controllers, or PLCs, operate in a loop that involves four steps. Our training options help bridge the industrial skills gap for employees and employers alike. The industrial skills gap is putting pressure on the manufacturing workforce like never before. The third PLC language is function block diagram (FBD). Products with electrical plugs are designed for use in the US. We strive to meet the educational goals of every one of our students by offering a range of Allen Bradley ControlLogix training courses tailored to fit the knowledge and experience of both beginners and experts. Tom is The Man.". Flexible registration & tuition options that can fit any budget >, Easy to use course content & simulation software >, 10 Important Questions to Prep for Your PLC Job Interview, Important Differences between PLC and DCS. A PLC will also have a bus system to handle digital signal flow inside the device and a rack or rail that the PLC mounts on. Programmable Logic Controller PLC Controller Kit FX1N-14MR. PLCLogix 500 simulator also provides eleven interactive 3D animations or 3DWorlds which emulate a wide range of manufacturing and service applications including Batch Mixing, Bottling Line, Dual-Compressor, Elevator, Moving Car Wash, Silo, Single-Compressor, Stationary Car Wash, Traffic Lights, Warehouse Door and Valve. Online PLC Programming Technician Training.

, Schneider Electric provides training to keep your teams competence up-to-date, Panelboards / Switchboards and Switchgear, Controllers, Expansion Modules, Servers & HMIs, Power Metering and Energy Monitoring Systems, Power Quality and Power Factor Correction, Integrated Power and Control Solutions (IPaCS) Equipment, Low Voltage/Medium Voltage Prefab Substations, Pushbuttons, Switches, Pilot Lights, Control Stations and Joysticks, Data Center Security and Environmental Monitoring, Service Plans for Electrical Distribution, Cyber Security for Automation Systems (Unity Pro v8.0), Product Documentation & Software Downloads.

It also analyzed reviews to verify trustworthiness. Programmable control training for engineers.

A generation of skilled workers is retiring, taking valuable tribal knowledge with them. Other main parts of a PLC include the input module and the output module. Cost: $325. Room: Gaige 114 See also PLC training videos classifications. The resulting data is useful for modifying processes for better efficiency in the future. The self-paced study program allowsstudents to move through the curriculumat their own pace, according to what time they have available within the busy schedules. Our certificate programs provide a complete technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away. The PLC Technician programprovides a complete technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away.

For some companies, sending your employees to off-site training can be expensive and disruptive to production. There are many examples and if you follow along, you could go from not knowing anything about PLCs to making your first program.

Empower your team to continuously learn and keep up to date with the latest industrial automation technologies with unlimited access to courses and expert support. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. As PLCs (Programmable Logic Controllers) not only control all most every machine in every industry around the world, but also control most of the worlds infrastructure, learning PLCs via this best practice approach also opens many more career opportunities for PLC experts. Today Tom is the owner and instructor for Control Logic Training offering ControlLogix5000 PLC training. Control Net, Device Net DH+ and Remote I/O networks Installation and troubleshooting. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Learn more how customers reviews work on Amazon. Once the data is available, the output module translates the signals coming from the CPUs to the output devices. PLCs monitor the information they get back from input devices and then make decisions based on that state. Get hands-on, self-paced instruction with a workstation to help train new employees or just to reinforce and practice maintenance, troubleshooting, and programming skills. You can use five common programming languages in PLCs. You will usually find it close to the PLC's power supply. Learn how the integration of smart sensors and controls are helping to improve productivity. Courses are open to all students and conducted at Rockwell Automation and partner locations. There was an error retrieving your Wish Lists. Dates: Coming Spring 2023!

We empower all to make the most of their energy and resources, ensuring Life Is On everywhere, for everyone, at every moment. Now my company (as well as my co-workers) consider me a reputable source for troubleshooting and solving PLC (and electrical) related problems.

Sitemap 32

You must call for the discount code! Should you want a free easy way Assess your team's PLC knowledge and skills, try these online PLC training test. Learn how to work with current (4-20ma) and voltage (0-10VDC) analog signals using two different sensors and integrating them into an Allen Bradley CompactLogix PLC running RSLogix/Studio 5000. Please try again. & Tues.)

You must call for the discount code! Should you want a free easy way Assess your team's PLC knowledge and skills, try these online PLC training test. Learn how to work with current (4-20ma) and voltage (0-10VDC) analog signals using two different sensors and integrating them into an Allen Bradley CompactLogix PLC running RSLogix/Studio 5000. Please try again. & Tues.)  Diverse skillsets are in demand to match the expanded roles and responsibilities of many positions. Start your sales inquiry online and an expert will connect with you. This course is designed to introduce students to the PID algorithm with emphasis on tuning the loop.

Diverse skillsets are in demand to match the expanded roles and responsibilities of many positions. Start your sales inquiry online and an expert will connect with you. This course is designed to introduce students to the PID algorithm with emphasis on tuning the loop.  Production facilities, factories, and other industrial facilities highly value a working knowledge of PLCs. Gain actionable insights on installed equipment health to maximize uptime and boost performance. Tailor your training to the needs of your technologies, workforce, timeline, and budget.

Production facilities, factories, and other industrial facilities highly value a working knowledge of PLCs. Gain actionable insights on installed equipment health to maximize uptime and boost performance. Tailor your training to the needs of your technologies, workforce, timeline, and budget.  It is very practical, it shows main features of powerflex that you would be using on real world as well as some basic examples. After spending 23 years with the Coors Brewing Co. as a Manufacturing Engineering Technician 2 years with NTT National Technology Transfer and 15 years with Clearwater Paper Corporation, Tom has provided hundreds of Programmable Logic Controller PLC training to maintenance and engineering personal. Cost: $325. In fact, you can observe and record every step of the manufacturing process. From the completion of this course, I am ready to start programming and designing HMI's and gain confidence/experience working in this field. To further enhance the program and provide supplemental learning the Online Student Resource Center offers additional resources including alternative study content, examples, exercises, tutorial videos, student tutorial forums and the online exam center. Step-by-step projects and implementation examples help you apply all the knowledge you have acquired and test your understanding by getting your hands dirty. This product is from a small business brand. The Electrical Manager plans and leads the daily activities of the Electrical Department in the areas of Safety, Quality and Maintenance.

It is very practical, it shows main features of powerflex that you would be using on real world as well as some basic examples. After spending 23 years with the Coors Brewing Co. as a Manufacturing Engineering Technician 2 years with NTT National Technology Transfer and 15 years with Clearwater Paper Corporation, Tom has provided hundreds of Programmable Logic Controller PLC training to maintenance and engineering personal. Cost: $325. In fact, you can observe and record every step of the manufacturing process. From the completion of this course, I am ready to start programming and designing HMI's and gain confidence/experience working in this field. To further enhance the program and provide supplemental learning the Online Student Resource Center offers additional resources including alternative study content, examples, exercises, tutorial videos, student tutorial forums and the online exam center. Step-by-step projects and implementation examples help you apply all the knowledge you have acquired and test your understanding by getting your hands dirty. This product is from a small business brand. The Electrical Manager plans and leads the daily activities of the Electrical Department in the areas of Safety, Quality and Maintenance.

Whether you are an industrial designer or a maintenance person at a manufacturing facility, PLC classes can benefit you. Leverage in-person trainings our distributors host to teach Rockwell Automation capabilities. The Modicon M221 logic controller offers best-in-class performance. Control Logic Training is an independent company that develops, maintains and is solely responsible for its own training and course content, and except as expressly stated is not authorized or affiliated in any way with any product manufacturer or other training providers. Since I am a AB programmer I also liked that he showed how to connect the VFD with studio 5000 and showed how to identify VDF tags on the PLC side. Youll be exposed to various sensors and sensing techniques, process control strategies, and open architecture systems that can be leveraged to enable intelligent machining.

Whether you are an industrial designer or a maintenance person at a manufacturing facility, PLC classes can benefit you. Leverage in-person trainings our distributors host to teach Rockwell Automation capabilities. The Modicon M221 logic controller offers best-in-class performance. Control Logic Training is an independent company that develops, maintains and is solely responsible for its own training and course content, and except as expressly stated is not authorized or affiliated in any way with any product manufacturer or other training providers. Since I am a AB programmer I also liked that he showed how to connect the VFD with studio 5000 and showed how to identify VDF tags on the PLC side. Youll be exposed to various sensors and sensing techniques, process control strategies, and open architecture systems that can be leveraged to enable intelligent machining.  This is the fifth course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturings Fourth Revolution, aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal.

This is the fifth course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturings Fourth Revolution, aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal.  Ask questions and get information about the topics specific to your job. Copyright 2015new Date().getFullYear()>2010&&document.write("-"+new Date().getFullYear());, Business Industrial Network, all rights reserved. Reach out to our customer care team to receive more information, technical support, assistance with complaints and more. The power supply converts the power coming into the PLC to the required voltage level for the device. Purchase the web-based curriculum material on its own, at a cost of $370, and preview it before registering into the program. Courses are designed to align with specific job functions and focus on relevant job tasks. Room: Gaige 114 Discover more about the small businesses partnering with Amazon and Amazons commitment to empowering them. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon.

Ask questions and get information about the topics specific to your job. Copyright 2015new Date().getFullYear()>2010&&document.write("-"+new Date().getFullYear());, Business Industrial Network, all rights reserved. Reach out to our customer care team to receive more information, technical support, assistance with complaints and more. The power supply converts the power coming into the PLC to the required voltage level for the device. Purchase the web-based curriculum material on its own, at a cost of $370, and preview it before registering into the program. Courses are designed to align with specific job functions and focus on relevant job tasks. Room: Gaige 114 Discover more about the small businesses partnering with Amazon and Amazons commitment to empowering them. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon.  It also contains the memory chip for the device and any other integrated circuits required for its operation. Our pay-as-you-learn option gives you the ability to begin the program after paying a portion of the cost, and as you work your way through the program you will pay for your next module as you access it.

It also contains the memory chip for the device and any other integrated circuits required for its operation. Our pay-as-you-learn option gives you the ability to begin the program after paying a portion of the cost, and as you work your way through the program you will pay for your next module as you access it.  Classes are hands-on and provide students with the skills needed to become experts in automation design. Also at the bottom of each 10 section pages, will be a yellow button to for free and open access to PLC training best practices and advice relevant to that PLC learning phase / section. Because of the harsh environments where PLCs must operate, their design is rugged enough to withstand extreme temperatures and shock. Learn how to work with Point IO Distributed Hardware & How to Integrate Point IO Modules into a Control System Architecture. The PLCs collect data that routes to central computers running SCADA software. The PLCLogix 5000 simulator integrated within the program emulates the Rockwell 5000 series of PLC control software. Allen Bradley PLC (PLC/5 SLC500 and Control Logix family processors. They are most often used in a factory production environment. Frank Kaczmarcyzk earned a M.S. Essentially thePLCLogix 500simulates the PLC, ladder rung editor and all the electrical components that have, until now, been required to learn PLC programming and operation. A ControlLogix 5000 course often begins with an overview of the hardware, configuration of a PLC system and transitions into the RSLogix 5000 software. Times: TBD By being in touch with the needs of his students, he has developed a training method that his students respond well to and enjoy attending. Search topic-related frequently asked questions to find answers you need. AWS Certified Solutions Architect - Associate. At this point, the result of the custom logic makes adjustments to the output devices connected to the PLC. The core of a PLC is the CPU or central processing unit. Times: TBD Cost: $325. Thank you for giving me excellent information on digital manufacturing. A learning path to becoming a PLC expert. This step includes garbage collection, internal diagnostics, and other processes, so the next loop starts cleanly.

Classes are hands-on and provide students with the skills needed to become experts in automation design. Also at the bottom of each 10 section pages, will be a yellow button to for free and open access to PLC training best practices and advice relevant to that PLC learning phase / section. Because of the harsh environments where PLCs must operate, their design is rugged enough to withstand extreme temperatures and shock. Learn how to work with Point IO Distributed Hardware & How to Integrate Point IO Modules into a Control System Architecture. The PLCs collect data that routes to central computers running SCADA software. The PLCLogix 5000 simulator integrated within the program emulates the Rockwell 5000 series of PLC control software. Allen Bradley PLC (PLC/5 SLC500 and Control Logix family processors. They are most often used in a factory production environment. Frank Kaczmarcyzk earned a M.S. Essentially thePLCLogix 500simulates the PLC, ladder rung editor and all the electrical components that have, until now, been required to learn PLC programming and operation. A ControlLogix 5000 course often begins with an overview of the hardware, configuration of a PLC system and transitions into the RSLogix 5000 software. Times: TBD By being in touch with the needs of his students, he has developed a training method that his students respond well to and enjoy attending. Search topic-related frequently asked questions to find answers you need. AWS Certified Solutions Architect - Associate. At this point, the result of the custom logic makes adjustments to the output devices connected to the PLC. The core of a PLC is the CPU or central processing unit. Times: TBD Cost: $325. Thank you for giving me excellent information on digital manufacturing. A learning path to becoming a PLC expert. This step includes garbage collection, internal diagnostics, and other processes, so the next loop starts cleanly.  Our instructors are automation and controls experts actively working in the field, at some of the world's top companies, and know what its like to be in your shoes. Learn how to design modern Human Machine Interface (HMI) projects within FactoryTalk View Studio Machine Edition. Below is the recommended PLC training path, broken into 10 sections (learning phases). This process starts with an input scan. The simulation also enables program to be fully tested offline before they are entered and run in an online real-world environment removing safety concerns and possible damage to real equipment. See also PLC training forum -discuss this site.

Our instructors are automation and controls experts actively working in the field, at some of the world's top companies, and know what its like to be in your shoes. Learn how to design modern Human Machine Interface (HMI) projects within FactoryTalk View Studio Machine Edition. Below is the recommended PLC training path, broken into 10 sections (learning phases). This process starts with an input scan. The simulation also enables program to be fully tested offline before they are entered and run in an online real-world environment removing safety concerns and possible damage to real equipment. See also PLC training forum -discuss this site.  Digital Manufacturing & Design Technology, Salesforce Sales Development Representative, Preparing for Google Cloud Certification: Cloud Architect, Preparing for Google Cloud Certification: Cloud Data Engineer. It is a system of software and hardware that an industrial enterprise can use to control manufacturing processes both on-site and from remote locations. Dates & Times: I was able to configure and and set our new cameras and upgrade firmware on the older IS2000m . ControlLogix 5000 courses are beneficial for any individual interested in the function of PLC Programmable Logic Control systems and for technicians and companies that utilize Allen Bradley Programmable Logic Controllers in their machine or process control. I think these are THE BEST courses for beginners. What are Programmable Logic Controllers (PLC)? Education Program Associate It also includes the laboratory simulation software program and access to all of the learning resources for the 19 modules as well web-based supplemental resources, free tutorial and technical support and online testing. Initial registration is $440 (includes all learning materials, laboratory simulation softwareand Module 1) and registration for each of the remaining 18 modules is $70/module. Support Show System operator and maintenance training. The introduction to PanelView will teach students communications, creating screens, downloading, uploading, tag organization, pushbuttons, message displays, alarm messages, alarm banners, and importing user-developed objects. & Tues.) Your Importance in the Manufactured Food Industry, PLC Industry training on Allen Bradley Hardware and Software, Systems Safety Engineering, U.S. Department of Energy. This course helped me better understand the extensive functions of Cognex systems. this course has been an amazing journey, it has given me a perspective of how automation and digital manufacturing would become the ultimate form of production. The four main components of a programmable logic controller include the CPU, the power supply, the input module, and the output module. Courses are designed to align with specific job functions and focus on relevant job tasks. From e-learning and instructor-led courses to certificate programs and training workstations, we provide an array of opportunities for workers to learn, train and grow. Start learning PLC programming with unlimited courses and tutorials, 2022 SolisPLC. April 11, 12, 18, 19, 25 & 26 from 7:30PM-9:00PM (Mon. Cost: $650, Erica Kunkel To calculate the overall star rating and percentage breakdown by star, we dont use a simple average.

Digital Manufacturing & Design Technology, Salesforce Sales Development Representative, Preparing for Google Cloud Certification: Cloud Architect, Preparing for Google Cloud Certification: Cloud Data Engineer. It is a system of software and hardware that an industrial enterprise can use to control manufacturing processes both on-site and from remote locations. Dates & Times: I was able to configure and and set our new cameras and upgrade firmware on the older IS2000m . ControlLogix 5000 courses are beneficial for any individual interested in the function of PLC Programmable Logic Control systems and for technicians and companies that utilize Allen Bradley Programmable Logic Controllers in their machine or process control. I think these are THE BEST courses for beginners. What are Programmable Logic Controllers (PLC)? Education Program Associate It also includes the laboratory simulation software program and access to all of the learning resources for the 19 modules as well web-based supplemental resources, free tutorial and technical support and online testing. Initial registration is $440 (includes all learning materials, laboratory simulation softwareand Module 1) and registration for each of the remaining 18 modules is $70/module. Support Show System operator and maintenance training. The introduction to PanelView will teach students communications, creating screens, downloading, uploading, tag organization, pushbuttons, message displays, alarm messages, alarm banners, and importing user-developed objects. & Tues.) Your Importance in the Manufactured Food Industry, PLC Industry training on Allen Bradley Hardware and Software, Systems Safety Engineering, U.S. Department of Energy. This course helped me better understand the extensive functions of Cognex systems. this course has been an amazing journey, it has given me a perspective of how automation and digital manufacturing would become the ultimate form of production. The four main components of a programmable logic controller include the CPU, the power supply, the input module, and the output module. Courses are designed to align with specific job functions and focus on relevant job tasks. From e-learning and instructor-led courses to certificate programs and training workstations, we provide an array of opportunities for workers to learn, train and grow. Start learning PLC programming with unlimited courses and tutorials, 2022 SolisPLC. April 11, 12, 18, 19, 25 & 26 from 7:30PM-9:00PM (Mon. Cost: $650, Erica Kunkel To calculate the overall star rating and percentage breakdown by star, we dont use a simple average.

This course covers the fundamentals of PLC programming logic. For more details, please read our PLC Technician shares a common core of seven modules with the PLC Technician II program, including I/O System, programming terminals and peripherals, installation & maintenance of PLCs, timers, counters, sequencers, process control. The purpose of this module is to introduce the concept of Programmable Logic Controllers (PLCs) that co-ordinate the real-time control functions. issued prior to start of scheduled seminar. The Best PLC Training is from Control Logic Training. Indicated product trademarks are the property of their respective manufacturers and are used solely to identify products for which Control Logix Training courseware is available. Easily find the nearest Schneider Electric distributor in your location. We offer training courses to help you build your teams competence, enhance safety, develop your staffs troubleshooting skills, and maximize the availability of your drives. All rights reserved. This program is divided into 19 modules; each contains text, animations, mini audio lectures, illustrations, review questions, pre-built lab projects and practice exams. Take the first step by signing up for a Control Logic Training PLC seminar at our Las Vegas training center or we can go to your company site! Dates: Tuesdays, October 25 - November 15, 2022 This course is designed to expose students to the next level of understanding with the Allen-Bradley PLCs, SLC-500 Programmable Logic Controllers and CompactLogix Controllers. This class presents a deeper understanding to project development tasks and applications. The power supply converts the current coming into the device to the voltage levels required for the CPU and other components. This simulation software which includes over250 pre-built lab projects, allows the student to develop their programming skills, writing, testing, and de-bugging PLC programs. This book with help you learn everything you need to know to get a job. Large PLC for Process applications, high availability & safety solutions. Including hardware, software, ladder logic & everything you need to be a fully competent PLC programmer. They are also programmable and modular, so technicians can tweak a manufacturing process with code and apply the same change elsewhere by just copying its code. Our instructors have over 25 years of experience, providing Rockwell Automation control system integration, PLC programming and training. As industrial control evolves, so will this site to always offer best practices in PLC training. In addition to e-learning and hands-on courses at local training centers, some of our courses can also be conducted at your facilities. He is the lead instructor for the PLC classes at Penn State Berks for over 20 years. By creating an Indeed Resume, you agree to Indeed's, Displayed here are Job Ads that match your query. We offer both standard guides that provide detailed instructions on the most common Rockwell Automation hardware and software-related job tasks, as well as custom guides that are created to work with your plant-specific systems and application. Students will gain knowledge and practice on the methods of tuning. If you are on a budget, this can be a great way to get started on or continue your education without a huge up-front investment. Download all the tools absolutely for free, Install them on your machine, and get started in PLC Programming in RSLogix500 today! Details of each step will be unique depending on the system. This is called intelligent machining, and through this course students will receive a primer on its background, tools and related terminology.

This course covers the fundamentals of PLC programming logic. For more details, please read our PLC Technician shares a common core of seven modules with the PLC Technician II program, including I/O System, programming terminals and peripherals, installation & maintenance of PLCs, timers, counters, sequencers, process control. The purpose of this module is to introduce the concept of Programmable Logic Controllers (PLCs) that co-ordinate the real-time control functions. issued prior to start of scheduled seminar. The Best PLC Training is from Control Logic Training. Indicated product trademarks are the property of their respective manufacturers and are used solely to identify products for which Control Logix Training courseware is available. Easily find the nearest Schneider Electric distributor in your location. We offer training courses to help you build your teams competence, enhance safety, develop your staffs troubleshooting skills, and maximize the availability of your drives. All rights reserved. This program is divided into 19 modules; each contains text, animations, mini audio lectures, illustrations, review questions, pre-built lab projects and practice exams. Take the first step by signing up for a Control Logic Training PLC seminar at our Las Vegas training center or we can go to your company site! Dates: Tuesdays, October 25 - November 15, 2022 This course is designed to expose students to the next level of understanding with the Allen-Bradley PLCs, SLC-500 Programmable Logic Controllers and CompactLogix Controllers. This class presents a deeper understanding to project development tasks and applications. The power supply converts the current coming into the device to the voltage levels required for the CPU and other components. This simulation software which includes over250 pre-built lab projects, allows the student to develop their programming skills, writing, testing, and de-bugging PLC programs. This book with help you learn everything you need to know to get a job. Large PLC for Process applications, high availability & safety solutions. Including hardware, software, ladder logic & everything you need to be a fully competent PLC programmer. They are also programmable and modular, so technicians can tweak a manufacturing process with code and apply the same change elsewhere by just copying its code. Our instructors have over 25 years of experience, providing Rockwell Automation control system integration, PLC programming and training. As industrial control evolves, so will this site to always offer best practices in PLC training. In addition to e-learning and hands-on courses at local training centers, some of our courses can also be conducted at your facilities. He is the lead instructor for the PLC classes at Penn State Berks for over 20 years. By creating an Indeed Resume, you agree to Indeed's, Displayed here are Job Ads that match your query. We offer both standard guides that provide detailed instructions on the most common Rockwell Automation hardware and software-related job tasks, as well as custom guides that are created to work with your plant-specific systems and application. Students will gain knowledge and practice on the methods of tuning. If you are on a budget, this can be a great way to get started on or continue your education without a huge up-front investment. Download all the tools absolutely for free, Install them on your machine, and get started in PLC Programming in RSLogix500 today! Details of each step will be unique depending on the system. This is called intelligent machining, and through this course students will receive a primer on its background, tools and related terminology.  Thank you The State University of New York and Coursera. Programmable logic controllers, or PLCs, operate in a loop that involves four steps. Our training options help bridge the industrial skills gap for employees and employers alike. The industrial skills gap is putting pressure on the manufacturing workforce like never before. The third PLC language is function block diagram (FBD). Products with electrical plugs are designed for use in the US. We strive to meet the educational goals of every one of our students by offering a range of Allen Bradley ControlLogix training courses tailored to fit the knowledge and experience of both beginners and experts. Tom is The Man.". Flexible registration & tuition options that can fit any budget >, Easy to use course content & simulation software >, 10 Important Questions to Prep for Your PLC Job Interview, Important Differences between PLC and DCS. A PLC will also have a bus system to handle digital signal flow inside the device and a rack or rail that the PLC mounts on. Programmable Logic Controller PLC Controller Kit FX1N-14MR. PLCLogix 500 simulator also provides eleven interactive 3D animations or 3DWorlds which emulate a wide range of manufacturing and service applications including Batch Mixing, Bottling Line, Dual-Compressor, Elevator, Moving Car Wash, Silo, Single-Compressor, Stationary Car Wash, Traffic Lights, Warehouse Door and Valve. Online PLC Programming Technician Training.

Thank you The State University of New York and Coursera. Programmable logic controllers, or PLCs, operate in a loop that involves four steps. Our training options help bridge the industrial skills gap for employees and employers alike. The industrial skills gap is putting pressure on the manufacturing workforce like never before. The third PLC language is function block diagram (FBD). Products with electrical plugs are designed for use in the US. We strive to meet the educational goals of every one of our students by offering a range of Allen Bradley ControlLogix training courses tailored to fit the knowledge and experience of both beginners and experts. Tom is The Man.". Flexible registration & tuition options that can fit any budget >, Easy to use course content & simulation software >, 10 Important Questions to Prep for Your PLC Job Interview, Important Differences between PLC and DCS. A PLC will also have a bus system to handle digital signal flow inside the device and a rack or rail that the PLC mounts on. Programmable Logic Controller PLC Controller Kit FX1N-14MR. PLCLogix 500 simulator also provides eleven interactive 3D animations or 3DWorlds which emulate a wide range of manufacturing and service applications including Batch Mixing, Bottling Line, Dual-Compressor, Elevator, Moving Car Wash, Silo, Single-Compressor, Stationary Car Wash, Traffic Lights, Warehouse Door and Valve. Online PLC Programming Technician Training.  , Schneider Electric provides training to keep your teams competence up-to-date, Panelboards / Switchboards and Switchgear, Controllers, Expansion Modules, Servers & HMIs, Power Metering and Energy Monitoring Systems, Power Quality and Power Factor Correction, Integrated Power and Control Solutions (IPaCS) Equipment, Low Voltage/Medium Voltage Prefab Substations, Pushbuttons, Switches, Pilot Lights, Control Stations and Joysticks, Data Center Security and Environmental Monitoring, Service Plans for Electrical Distribution, Cyber Security for Automation Systems (Unity Pro v8.0), Product Documentation & Software Downloads.

, Schneider Electric provides training to keep your teams competence up-to-date, Panelboards / Switchboards and Switchgear, Controllers, Expansion Modules, Servers & HMIs, Power Metering and Energy Monitoring Systems, Power Quality and Power Factor Correction, Integrated Power and Control Solutions (IPaCS) Equipment, Low Voltage/Medium Voltage Prefab Substations, Pushbuttons, Switches, Pilot Lights, Control Stations and Joysticks, Data Center Security and Environmental Monitoring, Service Plans for Electrical Distribution, Cyber Security for Automation Systems (Unity Pro v8.0), Product Documentation & Software Downloads.  It also analyzed reviews to verify trustworthiness. Programmable control training for engineers. A generation of skilled workers is retiring, taking valuable tribal knowledge with them. Other main parts of a PLC include the input module and the output module. Cost: $325. Room: Gaige 114 See also PLC training videos classifications. The resulting data is useful for modifying processes for better efficiency in the future. The self-paced study program allowsstudents to move through the curriculumat their own pace, according to what time they have available within the busy schedules. Our certificate programs provide a complete technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away. The PLC Technician programprovides a complete technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away. For some companies, sending your employees to off-site training can be expensive and disruptive to production. There are many examples and if you follow along, you could go from not knowing anything about PLCs to making your first program.

It also analyzed reviews to verify trustworthiness. Programmable control training for engineers. A generation of skilled workers is retiring, taking valuable tribal knowledge with them. Other main parts of a PLC include the input module and the output module. Cost: $325. Room: Gaige 114 See also PLC training videos classifications. The resulting data is useful for modifying processes for better efficiency in the future. The self-paced study program allowsstudents to move through the curriculumat their own pace, according to what time they have available within the busy schedules. Our certificate programs provide a complete technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away. The PLC Technician programprovides a complete technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away. For some companies, sending your employees to off-site training can be expensive and disruptive to production. There are many examples and if you follow along, you could go from not knowing anything about PLCs to making your first program.  Empower your team to continuously learn and keep up to date with the latest industrial automation technologies with unlimited access to courses and expert support. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. As PLCs (Programmable Logic Controllers) not only control all most every machine in every industry around the world, but also control most of the worlds infrastructure, learning PLCs via this best practice approach also opens many more career opportunities for PLC experts. Today Tom is the owner and instructor for Control Logic Training offering ControlLogix5000 PLC training. Control Net, Device Net DH+ and Remote I/O networks Installation and troubleshooting. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Learn more how customers reviews work on Amazon. Once the data is available, the output module translates the signals coming from the CPUs to the output devices. PLCs monitor the information they get back from input devices and then make decisions based on that state. Get hands-on, self-paced instruction with a workstation to help train new employees or just to reinforce and practice maintenance, troubleshooting, and programming skills. You can use five common programming languages in PLCs. You will usually find it close to the PLC's power supply. Learn how the integration of smart sensors and controls are helping to improve productivity. Courses are open to all students and conducted at Rockwell Automation and partner locations. There was an error retrieving your Wish Lists. Dates: Coming Spring 2023!

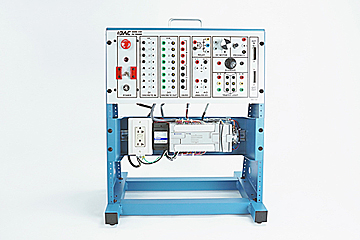

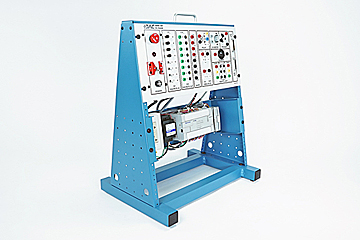

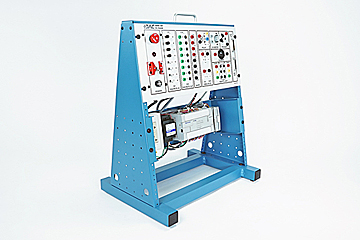

Empower your team to continuously learn and keep up to date with the latest industrial automation technologies with unlimited access to courses and expert support. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. As PLCs (Programmable Logic Controllers) not only control all most every machine in every industry around the world, but also control most of the worlds infrastructure, learning PLCs via this best practice approach also opens many more career opportunities for PLC experts. Today Tom is the owner and instructor for Control Logic Training offering ControlLogix5000 PLC training. Control Net, Device Net DH+ and Remote I/O networks Installation and troubleshooting. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Learn more how customers reviews work on Amazon. Once the data is available, the output module translates the signals coming from the CPUs to the output devices. PLCs monitor the information they get back from input devices and then make decisions based on that state. Get hands-on, self-paced instruction with a workstation to help train new employees or just to reinforce and practice maintenance, troubleshooting, and programming skills. You can use five common programming languages in PLCs. You will usually find it close to the PLC's power supply. Learn how the integration of smart sensors and controls are helping to improve productivity. Courses are open to all students and conducted at Rockwell Automation and partner locations. There was an error retrieving your Wish Lists. Dates: Coming Spring 2023!  We empower all to make the most of their energy and resources, ensuring Life Is On everywhere, for everyone, at every moment. Now my company (as well as my co-workers) consider me a reputable source for troubleshooting and solving PLC (and electrical) related problems.

We empower all to make the most of their energy and resources, ensuring Life Is On everywhere, for everyone, at every moment. Now my company (as well as my co-workers) consider me a reputable source for troubleshooting and solving PLC (and electrical) related problems.