The chemical system behind the battery is the main reason. Today, the energy density of lithium-ion batteries may have reached the limit. Zero-Volt Technology. However, the unstable interface between the anode or cathode and the electrolyte under a high voltage limits the energy density promotion.. As the electrolyte is the only shared component for both the cathode and anode, 2. Maximizing areal capacity

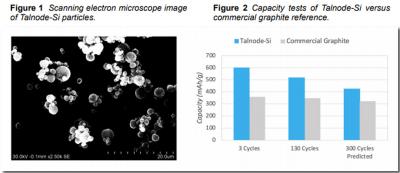

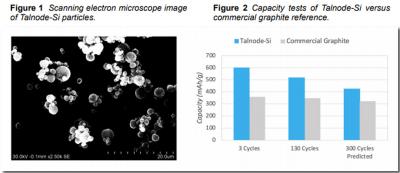

What determines the range of a new energy vehicle? Its unique carbon-based scaffolding keeps silicon in the most ideal formamorphous, nano-sized, and carbon-encased. Based in Silicon Valley, Sila was founded in 2011 to innovate in the area of battery materials. Energy storage is crucial in energy processes coupled with renewable energy generation and usage. Sometimes, silicon and titanium are also used in order to improve the power performance and lifespan of the battery. It aims to increase energy density to 330 Wh/kg and 1,000 Wh/I by the end of 2023. It is simultaneously developing SSBs with lithium-metal and silicon anodes, both of which will use a sulfide electrolyte. Silicon Composite Material For Lithium Battery New Energy Battery Production Line , Find Complete Details about Silicon Composite Material For Lithium Battery New Energy Battery Production Line,Silicon Composite Material For Lithium Battery,New Energy Battery Production Line,Silicon Composite Material from Lithium Ion Batteries Supplier or Increase the size of the electrical batteries: Electrical batteries manufacturers can increase the size of the original battery to achieve the effect of capacity expansion. Drawbacks such as the tremendous volume variation of silicon during the discharge/charge process, unstable solid electrolyte interphase films, and poor electrical conductivity, which significantly restrict its practical and commercial application of silicon anode.

The choice is vast; but which battery chemistry has the potential to win the race? Novel technique may lead to longer battery life in portable electronics and electrical vehicles However, as silicon anodes absorb electrons, they expand, leading to cracking and, therefore, seriously impacting battery life. The best lithium-sulfur batteries that are near commercialization have 500 watt-hours per kilogram. In 2020, the company said the latest generation of its fast-charging technology is able to charge a battery to 75% capacity in five minutes, thanks to energy densities of around 800 watt-hours (Wh) per liter.

LastModified24.02.201019:15:23PacificStandardTimePrinted | Polymer Binder for Silicon Anode Inventor: Dr. Gao Liu, PhD Presentation by: Blake Brundidge Morgan Hague Abraham Ringer Alexander Teran 1 Lithium-Ion Batteries Convert electrochemical energy to electricity Our stable silicon-carbon composite anode (SCC55) has five times the capacity of graphite and affords up to 50% more energy density than conventional graphite for lithium battery anodes. A startup called CalBattery is touting that their silicon-graphene anodes for li-ion batteries "will improve the anode specific capacity performance of lithium battery anodes by a factor of 3X." Abstract: According to the barrel theory, the height of the water level is determined by the shortest part of the barrel, and the lower limit of the energy density of lithium-ion batteries depends on the cathode material. my country proposed in the "13th Five-Year" new energy vehicle pilot project "High Specific Energy Lithium-ion Battery Technology", a common key technology research project, that by 2020, the Fast-Charging Electric Vehicle Technology. Battery manufacturer Amprius Technologies has delivered the first of its new 450 Wh/kg, 1150 Wh/L high energy density lithium-ion cells. Dec 15, 2021.

Todays high energy density NMC chemistries are still too expensive and dont offer performance competitive with existing combustion-engine vehicles. NREL is developing a low-cost method to overcome energy density and lifetime barriers faced by electric-drive vehicle batteries.

June 16, 2021 | NanoGraf has announced the highest energy density 18650 cylindrical lithium-ion cell in the world, achieving a 28% longer run time than traditional cell chemistries.. Aided by funding from the U.S. Department of Defense and others, NanoGrafs team of scientists, technologists, and engineers unveiled an 800 watt-hour per liter February 21, 2015 by Brian Wang. One new concept from the University of California in San Diego is to combine solid electrolytes with silicon anodes to produce a battery with significantly higher energy density than current commercial lithium-ion batteries Dec 15, 2021.

American Geosciences Institute.

The first next-gen battery material in market. The energy density of a battery is generally divided into two dimensions: weight energy density and volume energy density. SM-Silicon/3590 The Industry Standard Silicon for the Lithium-Ion Battery Industry Paraclete Energy, Inc. manufactures high-capacity, cycle-stable, oxide-free silicon that has a capacity of 3590 mAh/g for the lithium-ion battery market. Extreme Low Temperatures. VRFBs are non-flammable.

The increasing development of batterypowered vehicles for exceeding 500 km endurance has stimulated the exploration of lithium batteries with highenergydensity and highpowerdensity. Lithium Nickel-Cobalt-Aluminum Oxide (LiNi x Co y Al z O 2) 1. Determine (a): New supplies for lithium-air batteries developed by ALCA-SPRING venture. US-based OneD Battery Sciences has developed a silicon-based battery technology platform, called SINANODE. The biggest advantage of the NCM lithium battery is its high energy density, its energy storage density is usually above 200 Wh/kg, compared to the lithium iron phosphate 90-120 Wh/kg, this performance is more friendly to the lightweight design. Ampirus has shipped the first batch of what it calls the most energy-dense lithium batteries available today. What limits the energy density of lithium batteries. The chemical system behind the battery is the main reason. For instance, pristine silicon has a capacity of 3600 mAh/g while graphite is limited to a maximum theoretical capacity of 372 mAh/g. One of silicon's inherent traits, Silicon Nanofibers could boost lithium battery energy density by ten times.

Vanadium Redox Flow batteries are a good option for stationary battery storage but are not suited to EVs. However, significant challenges such as short cycle life and low coulombic efficiency have seriously hindered Nano-vault architecture mitigates stress in silicon-based anodes for lithium-ion batteries. byVglory 2021-04-04. 1200 450 100% 50+. Conventional li-ion battery with graphite vs. lithium-silicon battery with SCC55 One key performance improvement with SCC55 pertains to battery energy density. Determine (c): Demonstration of secure discharge/cost cycles of lithium-air batteries with energy density over 500Wh/kg operated on the room-temperature. Specific energy 1020 Wh/kg (3672 J/g) Energy density 1525 Wh/L (5465 kJ/L) VRFBs have a lifespan of 20+ years. Energy Storage.

Intelligence.

3) The cost is lower: Silicon materials are widely sourced, abundant, cheap to produce, and environmentally friendly. Tesla and legendary battery researcher Jeff Dahn are making progress to lithium metal batteries. Determine (b): Cell fabrication approach developed by the NIMS-SoftBank Superior Applied sciences Growth Middle.

A lot can be doneand a lot has been doneto make a better lithium-ion battery. Group14 Technologies makes lithium-silicon battery materials utilising its silicon anode. lithium ion manganese oxide (LiMn 2 O 4) Capacity ~148mAh/g (theoretical) Lower cost and lower toxicity than LCO; Energy density at cell level 150 to 220Wh/kg; NCA. Through our design, weve been able to gain back this loss, and we think our method has great potential to increase the operation time of batteries for portable electronics The first laboratory experiments with lithium-silicon materials took place in the early to mid 1970s. Anode materials account for 25% to 28% of the total cost of lithium batteries.

As the search continues for high-performing lithium-based battery systems, new combinations of materials and ideas are showing promise. Silicon anodes are famous for their energy density, which is 10 times greater than the graphite anodes most often used in todays commercial lithium ion batteries. Rechargeable silicon batteries. To learn more, we caught up with Vincent Pluvinage, Co-Founder and CEO. This volume expansion will cause: (1) the crushing of silicon particles and the separation of the coating from the copper current Generally speaking, the four parts of a lithium battery are very critical: the positive electrode, the negative electrode, the electrolyte, and the diaphragm. At present, the use of silicon-carbon composite materials to increase the energy density of batteries has become one of the development directions of lithium-ion battery anode materials recognized in the industry. Silicon-based materials also generally have a much larger specific capacity. Advanced anodes such as silicon are needed to enhance today's Li-ion cell energy densities and enable low cost, >200 mile rang\ e BEVs.

[Silicon-carbon anode material lithium battery energy far exceeds Tesla Model 3 battery] Amprius company in California has announced that it has produced the first batch of ultra-high energy density lithium battery, which has a battery density of 450Wh/kg (1150 Wh/l), making it the highest energy density lithium battery available at present.

Battery weight energy density = battery capacity discharge platform/weight, the basic unit is Wh/kg (watt hour/kg) Battery volume energy density = battery capacity discharge platform/volume, the basic unit is Wh/L (watt hour/liter) We can supply grams to tons today. the speci c capacity (C) of electrodes determined its energy density (E) like below: E CcCa/(Ca + Cc)(Vc Va) (1) It clearly illustrates that increasing the working voltage of aLIBorcapacityofelectrodescanimproveitsenergydensity.So in the case of anodes, silicon (Si) and lithium (Li) are the two It is believed that this might increase the energy density of lithium-ion batteries by a further 20% to 40%. Unparalleled Safety. Silicon anodes are famous for their energy density, which is 10 times greater than the graphite anodes most often used in today's commercial lithium ion batteries. The biggest advantage of the NCM lithium battery is its high energy density, its energy storage density is usually above 200 Wh/kg, compared to the lithium iron phosphate 90-120 Wh/kg, this performance is more friendly to the lightweight design.

Increase the size of the electrical batteries: Electrical batteries manufacturers can increase the size of the original battery to achieve the effect of capacity expansion. Determine (b): Cell fabrication approach developed by the NIMS-SoftBank Superior Applied sciences Growth Middle. A new lithium-ion battery designed by CalBattery, with a silicon-graphene anode, promises a dramatic energy density breakthrough, according to a news release issued by the company on Friday.

Among the developed batteries, the lithium-ion battery has shown better performance. Amprius claims that its lithium-ion batteries have the highest energy density available, with cells boasting 450 Watt-hours per kilogram (Wh/kg) and 1150 Watt-hours per liter (Wh/L). 1a ). Silicon carbon negative electrode. Obtaining a better energy density will come partly from SolidEnergys Solid Polymer Ionic Liquid (SPIL) electrolyte, which Hu claims, enables use of an ultra-thin lithium metal anode, and improves the cell-level energy density by 50 percent compared to graphite anodes and 30 percent compared to silicon-composite anodes.. How is the energy density of lithium batteries. Cobalt, Manganese, and LPF. A test battery constructed with the silicon anode was shown to have an energy density 25 percent higher than a comparable commercially available battery with a Energy density at cell level ~125Wh/kg (2021) Maximum theoretical cell level energy density ~170Wh/kg; LMO. Jan 27, 2021. The Rocky Mountain Institute surveyed potential battery technologies. Lithium-ion battery energy density big reveal. [Silicon-carbon anode material lithium battery energy far exceeds Tesla Model 3 battery] Amprius company in California has announced that it has produced the first batch of ultra-high energy density lithium battery, which has a battery density of 450Wh/kg (1150 Wh/l), making it the highest energy density lithium battery available at present. The mass-energy density of lithium-ion batteries with silicon cathode materials can be increased by more than 8% and the bulk energy density by more than 10%, while the cost per kWh of the battery can be reduced by at least 3%. And its fully compatible with existing battery manufacturing processes and factories, making the path to progress immediate. One potential replacement material is silicon, and significant research efforts are underway to commercialize so-called lithium-silicon batteries. Our technology optimizes the Enevate anode performance through a combination of electrolyte formulation, cell design, and cell formation. This battery has an energy density of 10 equal to that of a lithium-ion battery and uses air oxygen as the active material of the cathode and anode like a lithium-ion battery Performance of equalizer circuits for lithium-ion cells. A joint research team, affiliated with UNIST has unveiled a novel electrolyte additive that could enable a long lifespan and fast chargeability of high-energy-density Lithium-Ion Batteries (LIBs). battery pack sizes, energy density, chemistry and costs, as well as the rate of growth of the EV market by vehicle Silicon is already playing a key role in increasing energy density At present silicon blending with graphite is on average 4% for automotive applications, at Lithium metal is highly reactive EXAMPLE. Lithiumsulfur battery of practical interest requires thin-layer support to achieve acceptable volumetric energy density. The application prospects of silicon-carbon anode materials are getting brighter and brighter. Sila changes that. Our next-gen silicon material shatters that energy ceiling, improving energy density significantly without compromise. Silicon battery Presentation - Lithium Ion 1. But NanoGrafs silicon-anode battery, Wang said, packs ten percent more energy density than even the industrys top-performing 18650 cells. Jul 27, 2022. The lithium-ion battery market is projected to grow at a CAGR of 13.7% between 2017 and 2022, to a value of USD 67.7 billion. Experimental reports of up to 40% increase in energy density of Si anode based LIBs (Si-LIBs) have been reported in literature. By weight, Amprius Lithium is also a highly reactive element, meaning that a lot of energy can be stored in its atomic bonds. This translates into a very high energy density for lithium-ion batteries. Here is a way to get a perspective on the energy density. A typical lithium-ion battery can store 150 watt-hours of electricity in 1 kilogram of battery. The pure silicon anode is a key battery component. Silicon, as the material with the highest energy density, can take up a remarkable number of lithium ions. What determines the range of a new energy vehicle? By weight, Amprius Lithium-ion batteries (LIBs) have become the preferred power source for various consumer devices such as electronic gadgets due to their high As graphite anodes reach their limit in terms of power and energy density, battery makers are turning to highly-abundant material, silicon. Berdichevsky is well aware of the obstacles to the mass production of an EV-worthy lithium-silicon battery. Lithium and its Applications With an atomic number of 3 & a density of 0.534 g/cm3, Lithium is the first. 1. The above chart demonstrates the space required in a battery cell for the Communications Materials , 2021; 2 (1) DOI: 10.1038/s43246-021 In fact, large-format EV size cells achieve over 1000 Wh/L and 350 Wh/kg energy density. All EV Batteries. Silicon (Si) is under consideration as a potential next-generation anode material for the lithium ion battery (LIB). 18650, Pouch, Prismatic and Medical Device. Experimental reports of up to 40% increase in

EVreporter. Lithium iron phosphate, lithium nickel manganese cobalt, silicon, solid-state, sodium-ion. Companys proprietary platform of advanced materials will enable a safer EV battery with higher gravimetric energy density than conventional lithium-ion and solid state technologies. Anode materials include: Silicon: Silicon can store significantly more lithium ions than graphite. Silicon Composite Material For Lithium Battery New Energy Battery Production Line , Find Complete Details about Silicon Composite Material For Lithium Battery New Energy Battery Production Line,Silicon Composite Material For Lithium Battery,New Energy Battery Production Line,Silicon Composite Material from Lithium Ion Batteries Supplier or

However, as silicon anodes absorb electrons, they expand, leading to cracking and, therefore, seriously impacting battery life. At QuantumScape, we believe both high and low energy density battery chemistries need to improve. Si has received considerable attention as a replacement for graphite due to its high gravimetric (4200 mAh/g) and volumetric capacities (9786 mAh/cm3) when fully lithiated. In this case, Silicon-based anode materials have become an ideal material breakthrough point for power battery upgrades. @article{osti_1224802, title = {Silicon-Nanowire Based Lithium Ion Batteries for Vehicles With Double the Energy Density}, author = {Stefan, Ionel and Cohen, Yehonathan}, abstractNote = {Amprius researched and developed silicon nanowire anodes. As humans we typically perceive dangers from our experiences For example, some people focus on one factor that can cause a fire, like a lithium-ion battery in the bottom of a pile, when in actuality, fires can start many different ways. Lithium iron phosphate, lithium nickel manganese cobalt, silicon, solid-state, sodium-ion. Scientists develop novel high-energy-density lithium metal battery. Overall, about 90% of anodes in lithium-ion batteries are made of graphite. But NanoGrafs silicon-anode battery, Wang said, packs ten percent more energy density than even the industrys top-performing 18650 cells. The lithium-silicon technology developed by Group14 Technologies uses a silicon-carbon anode material, named SCC55, and has proven to significantly increase the energy density, reaching the 330-Wh/kg value in typical automotive cells with more than 1,000 charge-discharge cycles. Enevate's anode material cost is lower than graphite in terms of dollar per kWh. The energy density of the battery cell of Tesla BEVs using high nickel ternary material (LiNiCoAlO 2) is 300 Wh/kg, which is currently the highest level of energy density available for lithium-ion batteries. Lithium-ion Batteries. The energy density of lithium battery cells mainly depends on the breakthrough of the chemical system. Group14 says its next-generation silicon-based Silicon carbon negative electrode. Amprius then built and delivered high-energy lithium-ion cells that met the projects specific energy goal and In tests, Altech reported its anode material averaged energy retention capacity of ~430mAh/g, compared to a normal lithium-ion battery anode at around 330mAh/g. Abstract: According to the barrel theory, the height of the water level is determined by the shortest part of the barrel, and the lower limit of the energy density of lithium-ion batteries depends on the cathode material. my country proposed in the "13th Five-Year" new energy vehicle pilot project "High Specific Energy Lithium-ion Battery Technology", a common key technology research project, that by 2020, the Leader in Silicon Anode Generally speaking, the four parts of a lithium battery are very critical: the positive electrode, the negative electrode, the electrolyte, and the diaphragm. Panasonic, one of the world's largest lithium-ion battery manufacturer for electric vehicles, intends to noticeably improve the energy density of new cells by 2030. Energy Density. The potential of lithium ion (Li-ion) batteries to be the major energy storage in off-grid renewable energy is presented. Longer lifespan than other technologies along with higher energy and power densities are the most favorable attributes of Li-ion batteries. The Li-ion can be the battery of first choice for energy storage. Researchers at the University of California, Riversides Bourns College of Engineering have developed a novel paper-like material for lithium-ion batteries. In vehicles that require a lot of electricity, such as electric vehicles, it is necessary to use high-energy batteries. It adopts high-nickel ternary material as cathode material and silicon-carbon composites as anode material. High-energy-density lithium-ion batteries are a key research and development direction in my country, and also a disruptive change in the field of new energy. By Battery Power Online Staff .

Stanford University scientists have dramatically improved the performance of lithium-ion batteries by creating novel electrodes made of silicon and conducting polymer hydrogel, a spongy material similar to that used in contact lenses and other household products. There are four key parts of a lithium battery: anode, cathode, electrode and diaphragm, which all affect the batterys energy density. As consumer demand grows for battery-enabled technology, manufacturers are investing in battery research and development, with the goal of speeding the advancement of energy density in lithium-ion batteries. Will a 3X improvement in anode performance translate into a 3X improvement in energy density of the overall battery, or not? However, significant challenges such as short cycle life and low coulombic efficiency have seriously hindered Determine (a): New supplies for lithium-air batteries developed by ALCA-SPRING venture. Lithium air batteries could increase energy density by ten times. Silicon holds on to nine times more lithium ions than graphite does, so it has better energy density (thus expanding range by 20 percent). The energy density of lithium battery cells mainly depends on the breakthrough of the chemical system. Silicon is an earth abundant element, and is fairly inexpensive to refine to high purity.When alloyed with lithium it has a theoretical capacity of ~3,600 milliampere hours per gram (mAh/g), which is nearly 10 times the energy density of graphite electrodes, which exhibit a maximum capacity of 372 mAh/g for their fully lithiated state of LiC 6. However, this increase in energy density is achieved wh Skip to content. SiFAB has engineered a unique nanoporous fiber structure that accommodates swelling of silicon in lithium-ion batteries. By focusing on silicon anode technology, it claims

The lithium-ion batteries that sustain our lives arent equipped to power our future. Silicon coated carbon nanotubes and fibers and silicon and porous silicon-carbon composite The development of the new battery focused on commercialization from the outset. Wh/liter Wh/kg Independent patent filings on nanowire technology and lithium ion cells Silicon nanowire anode. Lithium ion batteries (LIBs) play a signi cantly important role in various energy storage technologies because of their high energy density.14 Since the rst commercial LIB came out in 1991, it has played Team develops stable, efficient, anode-free sodium battery. Our silicon anode products enable a leap in lithium-ion battery energy and power density. The increasing development of batterypowered vehicles for exceeding 500 km endurance has stimulated the exploration of lithium batteries with highenergydensity and highpowerdensity.

Jun 3, 2013. As the search continues for high-performing lithium-based battery systems, new combinations of materials and ideas are showing promise.

Sitemap 21

The chemical system behind the battery is the main reason. Today, the energy density of lithium-ion batteries may have reached the limit. Zero-Volt Technology. However, the unstable interface between the anode or cathode and the electrolyte under a high voltage limits the energy density promotion.. As the electrolyte is the only shared component for both the cathode and anode, 2. Maximizing areal capacity

The chemical system behind the battery is the main reason. Today, the energy density of lithium-ion batteries may have reached the limit. Zero-Volt Technology. However, the unstable interface between the anode or cathode and the electrolyte under a high voltage limits the energy density promotion.. As the electrolyte is the only shared component for both the cathode and anode, 2. Maximizing areal capacity  What determines the range of a new energy vehicle? Its unique carbon-based scaffolding keeps silicon in the most ideal formamorphous, nano-sized, and carbon-encased. Based in Silicon Valley, Sila was founded in 2011 to innovate in the area of battery materials. Energy storage is crucial in energy processes coupled with renewable energy generation and usage. Sometimes, silicon and titanium are also used in order to improve the power performance and lifespan of the battery. It aims to increase energy density to 330 Wh/kg and 1,000 Wh/I by the end of 2023. It is simultaneously developing SSBs with lithium-metal and silicon anodes, both of which will use a sulfide electrolyte. Silicon Composite Material For Lithium Battery New Energy Battery Production Line , Find Complete Details about Silicon Composite Material For Lithium Battery New Energy Battery Production Line,Silicon Composite Material For Lithium Battery,New Energy Battery Production Line,Silicon Composite Material from Lithium Ion Batteries Supplier or Increase the size of the electrical batteries: Electrical batteries manufacturers can increase the size of the original battery to achieve the effect of capacity expansion. Drawbacks such as the tremendous volume variation of silicon during the discharge/charge process, unstable solid electrolyte interphase films, and poor electrical conductivity, which significantly restrict its practical and commercial application of silicon anode.

What determines the range of a new energy vehicle? Its unique carbon-based scaffolding keeps silicon in the most ideal formamorphous, nano-sized, and carbon-encased. Based in Silicon Valley, Sila was founded in 2011 to innovate in the area of battery materials. Energy storage is crucial in energy processes coupled with renewable energy generation and usage. Sometimes, silicon and titanium are also used in order to improve the power performance and lifespan of the battery. It aims to increase energy density to 330 Wh/kg and 1,000 Wh/I by the end of 2023. It is simultaneously developing SSBs with lithium-metal and silicon anodes, both of which will use a sulfide electrolyte. Silicon Composite Material For Lithium Battery New Energy Battery Production Line , Find Complete Details about Silicon Composite Material For Lithium Battery New Energy Battery Production Line,Silicon Composite Material For Lithium Battery,New Energy Battery Production Line,Silicon Composite Material from Lithium Ion Batteries Supplier or Increase the size of the electrical batteries: Electrical batteries manufacturers can increase the size of the original battery to achieve the effect of capacity expansion. Drawbacks such as the tremendous volume variation of silicon during the discharge/charge process, unstable solid electrolyte interphase films, and poor electrical conductivity, which significantly restrict its practical and commercial application of silicon anode.  The choice is vast; but which battery chemistry has the potential to win the race? Novel technique may lead to longer battery life in portable electronics and electrical vehicles However, as silicon anodes absorb electrons, they expand, leading to cracking and, therefore, seriously impacting battery life. The best lithium-sulfur batteries that are near commercialization have 500 watt-hours per kilogram. In 2020, the company said the latest generation of its fast-charging technology is able to charge a battery to 75% capacity in five minutes, thanks to energy densities of around 800 watt-hours (Wh) per liter.

The choice is vast; but which battery chemistry has the potential to win the race? Novel technique may lead to longer battery life in portable electronics and electrical vehicles However, as silicon anodes absorb electrons, they expand, leading to cracking and, therefore, seriously impacting battery life. The best lithium-sulfur batteries that are near commercialization have 500 watt-hours per kilogram. In 2020, the company said the latest generation of its fast-charging technology is able to charge a battery to 75% capacity in five minutes, thanks to energy densities of around 800 watt-hours (Wh) per liter.  LastModified24.02.201019:15:23PacificStandardTimePrinted | Polymer Binder for Silicon Anode Inventor: Dr. Gao Liu, PhD Presentation by: Blake Brundidge Morgan Hague Abraham Ringer Alexander Teran 1 Lithium-Ion Batteries Convert electrochemical energy to electricity Our stable silicon-carbon composite anode (SCC55) has five times the capacity of graphite and affords up to 50% more energy density than conventional graphite for lithium battery anodes. A startup called CalBattery is touting that their silicon-graphene anodes for li-ion batteries "will improve the anode specific capacity performance of lithium battery anodes by a factor of 3X." Abstract: According to the barrel theory, the height of the water level is determined by the shortest part of the barrel, and the lower limit of the energy density of lithium-ion batteries depends on the cathode material. my country proposed in the "13th Five-Year" new energy vehicle pilot project "High Specific Energy Lithium-ion Battery Technology", a common key technology research project, that by 2020, the Fast-Charging Electric Vehicle Technology. Battery manufacturer Amprius Technologies has delivered the first of its new 450 Wh/kg, 1150 Wh/L high energy density lithium-ion cells. Dec 15, 2021.

LastModified24.02.201019:15:23PacificStandardTimePrinted | Polymer Binder for Silicon Anode Inventor: Dr. Gao Liu, PhD Presentation by: Blake Brundidge Morgan Hague Abraham Ringer Alexander Teran 1 Lithium-Ion Batteries Convert electrochemical energy to electricity Our stable silicon-carbon composite anode (SCC55) has five times the capacity of graphite and affords up to 50% more energy density than conventional graphite for lithium battery anodes. A startup called CalBattery is touting that their silicon-graphene anodes for li-ion batteries "will improve the anode specific capacity performance of lithium battery anodes by a factor of 3X." Abstract: According to the barrel theory, the height of the water level is determined by the shortest part of the barrel, and the lower limit of the energy density of lithium-ion batteries depends on the cathode material. my country proposed in the "13th Five-Year" new energy vehicle pilot project "High Specific Energy Lithium-ion Battery Technology", a common key technology research project, that by 2020, the Fast-Charging Electric Vehicle Technology. Battery manufacturer Amprius Technologies has delivered the first of its new 450 Wh/kg, 1150 Wh/L high energy density lithium-ion cells. Dec 15, 2021.  June 16, 2021 | NanoGraf has announced the highest energy density 18650 cylindrical lithium-ion cell in the world, achieving a 28% longer run time than traditional cell chemistries.. Aided by funding from the U.S. Department of Defense and others, NanoGrafs team of scientists, technologists, and engineers unveiled an 800 watt-hour per liter February 21, 2015 by Brian Wang. One new concept from the University of California in San Diego is to combine solid electrolytes with silicon anodes to produce a battery with significantly higher energy density than current commercial lithium-ion batteries Dec 15, 2021.

June 16, 2021 | NanoGraf has announced the highest energy density 18650 cylindrical lithium-ion cell in the world, achieving a 28% longer run time than traditional cell chemistries.. Aided by funding from the U.S. Department of Defense and others, NanoGrafs team of scientists, technologists, and engineers unveiled an 800 watt-hour per liter February 21, 2015 by Brian Wang. One new concept from the University of California in San Diego is to combine solid electrolytes with silicon anodes to produce a battery with significantly higher energy density than current commercial lithium-ion batteries Dec 15, 2021.  American Geosciences Institute.

American Geosciences Institute.  The first next-gen battery material in market. The energy density of a battery is generally divided into two dimensions: weight energy density and volume energy density. SM-Silicon/3590 The Industry Standard Silicon for the Lithium-Ion Battery Industry Paraclete Energy, Inc. manufactures high-capacity, cycle-stable, oxide-free silicon that has a capacity of 3590 mAh/g for the lithium-ion battery market. Extreme Low Temperatures. VRFBs are non-flammable.

The first next-gen battery material in market. The energy density of a battery is generally divided into two dimensions: weight energy density and volume energy density. SM-Silicon/3590 The Industry Standard Silicon for the Lithium-Ion Battery Industry Paraclete Energy, Inc. manufactures high-capacity, cycle-stable, oxide-free silicon that has a capacity of 3590 mAh/g for the lithium-ion battery market. Extreme Low Temperatures. VRFBs are non-flammable.  The increasing development of batterypowered vehicles for exceeding 500 km endurance has stimulated the exploration of lithium batteries with highenergydensity and highpowerdensity. Lithium Nickel-Cobalt-Aluminum Oxide (LiNi x Co y Al z O 2) 1. Determine (a): New supplies for lithium-air batteries developed by ALCA-SPRING venture. US-based OneD Battery Sciences has developed a silicon-based battery technology platform, called SINANODE. The biggest advantage of the NCM lithium battery is its high energy density, its energy storage density is usually above 200 Wh/kg, compared to the lithium iron phosphate 90-120 Wh/kg, this performance is more friendly to the lightweight design. Ampirus has shipped the first batch of what it calls the most energy-dense lithium batteries available today. What limits the energy density of lithium batteries. The chemical system behind the battery is the main reason. For instance, pristine silicon has a capacity of 3600 mAh/g while graphite is limited to a maximum theoretical capacity of 372 mAh/g. One of silicon's inherent traits, Silicon Nanofibers could boost lithium battery energy density by ten times.

The increasing development of batterypowered vehicles for exceeding 500 km endurance has stimulated the exploration of lithium batteries with highenergydensity and highpowerdensity. Lithium Nickel-Cobalt-Aluminum Oxide (LiNi x Co y Al z O 2) 1. Determine (a): New supplies for lithium-air batteries developed by ALCA-SPRING venture. US-based OneD Battery Sciences has developed a silicon-based battery technology platform, called SINANODE. The biggest advantage of the NCM lithium battery is its high energy density, its energy storage density is usually above 200 Wh/kg, compared to the lithium iron phosphate 90-120 Wh/kg, this performance is more friendly to the lightweight design. Ampirus has shipped the first batch of what it calls the most energy-dense lithium batteries available today. What limits the energy density of lithium batteries. The chemical system behind the battery is the main reason. For instance, pristine silicon has a capacity of 3600 mAh/g while graphite is limited to a maximum theoretical capacity of 372 mAh/g. One of silicon's inherent traits, Silicon Nanofibers could boost lithium battery energy density by ten times.  Vanadium Redox Flow batteries are a good option for stationary battery storage but are not suited to EVs. However, significant challenges such as short cycle life and low coulombic efficiency have seriously hindered Nano-vault architecture mitigates stress in silicon-based anodes for lithium-ion batteries. byVglory 2021-04-04. 1200 450 100% 50+. Conventional li-ion battery with graphite vs. lithium-silicon battery with SCC55 One key performance improvement with SCC55 pertains to battery energy density. Determine (c): Demonstration of secure discharge/cost cycles of lithium-air batteries with energy density over 500Wh/kg operated on the room-temperature. Specific energy 1020 Wh/kg (3672 J/g) Energy density 1525 Wh/L (5465 kJ/L) VRFBs have a lifespan of 20+ years. Energy Storage.

Vanadium Redox Flow batteries are a good option for stationary battery storage but are not suited to EVs. However, significant challenges such as short cycle life and low coulombic efficiency have seriously hindered Nano-vault architecture mitigates stress in silicon-based anodes for lithium-ion batteries. byVglory 2021-04-04. 1200 450 100% 50+. Conventional li-ion battery with graphite vs. lithium-silicon battery with SCC55 One key performance improvement with SCC55 pertains to battery energy density. Determine (c): Demonstration of secure discharge/cost cycles of lithium-air batteries with energy density over 500Wh/kg operated on the room-temperature. Specific energy 1020 Wh/kg (3672 J/g) Energy density 1525 Wh/L (5465 kJ/L) VRFBs have a lifespan of 20+ years. Energy Storage.  Intelligence.

Intelligence.  3) The cost is lower: Silicon materials are widely sourced, abundant, cheap to produce, and environmentally friendly. Tesla and legendary battery researcher Jeff Dahn are making progress to lithium metal batteries. Determine (b): Cell fabrication approach developed by the NIMS-SoftBank Superior Applied sciences Growth Middle.

3) The cost is lower: Silicon materials are widely sourced, abundant, cheap to produce, and environmentally friendly. Tesla and legendary battery researcher Jeff Dahn are making progress to lithium metal batteries. Determine (b): Cell fabrication approach developed by the NIMS-SoftBank Superior Applied sciences Growth Middle.  A lot can be doneand a lot has been doneto make a better lithium-ion battery. Group14 Technologies makes lithium-silicon battery materials utilising its silicon anode. lithium ion manganese oxide (LiMn 2 O 4) Capacity ~148mAh/g (theoretical) Lower cost and lower toxicity than LCO; Energy density at cell level 150 to 220Wh/kg; NCA. Through our design, weve been able to gain back this loss, and we think our method has great potential to increase the operation time of batteries for portable electronics The first laboratory experiments with lithium-silicon materials took place in the early to mid 1970s. Anode materials account for 25% to 28% of the total cost of lithium batteries.

A lot can be doneand a lot has been doneto make a better lithium-ion battery. Group14 Technologies makes lithium-silicon battery materials utilising its silicon anode. lithium ion manganese oxide (LiMn 2 O 4) Capacity ~148mAh/g (theoretical) Lower cost and lower toxicity than LCO; Energy density at cell level 150 to 220Wh/kg; NCA. Through our design, weve been able to gain back this loss, and we think our method has great potential to increase the operation time of batteries for portable electronics The first laboratory experiments with lithium-silicon materials took place in the early to mid 1970s. Anode materials account for 25% to 28% of the total cost of lithium batteries.  As the search continues for high-performing lithium-based battery systems, new combinations of materials and ideas are showing promise. Silicon anodes are famous for their energy density, which is 10 times greater than the graphite anodes most often used in todays commercial lithium ion batteries. Rechargeable silicon batteries. To learn more, we caught up with Vincent Pluvinage, Co-Founder and CEO. This volume expansion will cause: (1) the crushing of silicon particles and the separation of the coating from the copper current Generally speaking, the four parts of a lithium battery are very critical: the positive electrode, the negative electrode, the electrolyte, and the diaphragm. At present, the use of silicon-carbon composite materials to increase the energy density of batteries has become one of the development directions of lithium-ion battery anode materials recognized in the industry. Silicon-based materials also generally have a much larger specific capacity. Advanced anodes such as silicon are needed to enhance today's Li-ion cell energy densities and enable low cost, >200 mile rang\ e BEVs.

As the search continues for high-performing lithium-based battery systems, new combinations of materials and ideas are showing promise. Silicon anodes are famous for their energy density, which is 10 times greater than the graphite anodes most often used in todays commercial lithium ion batteries. Rechargeable silicon batteries. To learn more, we caught up with Vincent Pluvinage, Co-Founder and CEO. This volume expansion will cause: (1) the crushing of silicon particles and the separation of the coating from the copper current Generally speaking, the four parts of a lithium battery are very critical: the positive electrode, the negative electrode, the electrolyte, and the diaphragm. At present, the use of silicon-carbon composite materials to increase the energy density of batteries has become one of the development directions of lithium-ion battery anode materials recognized in the industry. Silicon-based materials also generally have a much larger specific capacity. Advanced anodes such as silicon are needed to enhance today's Li-ion cell energy densities and enable low cost, >200 mile rang\ e BEVs.  [Silicon-carbon anode material lithium battery energy far exceeds Tesla Model 3 battery] Amprius company in California has announced that it has produced the first batch of ultra-high energy density lithium battery, which has a battery density of 450Wh/kg (1150 Wh/l), making it the highest energy density lithium battery available at present.

[Silicon-carbon anode material lithium battery energy far exceeds Tesla Model 3 battery] Amprius company in California has announced that it has produced the first batch of ultra-high energy density lithium battery, which has a battery density of 450Wh/kg (1150 Wh/l), making it the highest energy density lithium battery available at present.

Battery weight energy density = battery capacity discharge platform/weight, the basic unit is Wh/kg (watt hour/kg) Battery volume energy density = battery capacity discharge platform/volume, the basic unit is Wh/L (watt hour/liter) We can supply grams to tons today. the speci c capacity (C) of electrodes determined its energy density (E) like below: E CcCa/(Ca + Cc)(Vc Va) (1) It clearly illustrates that increasing the working voltage of aLIBorcapacityofelectrodescanimproveitsenergydensity.So in the case of anodes, silicon (Si) and lithium (Li) are the two It is believed that this might increase the energy density of lithium-ion batteries by a further 20% to 40%. Unparalleled Safety. Silicon anodes are famous for their energy density, which is 10 times greater than the graphite anodes most often used in today's commercial lithium ion batteries. The biggest advantage of the NCM lithium battery is its high energy density, its energy storage density is usually above 200 Wh/kg, compared to the lithium iron phosphate 90-120 Wh/kg, this performance is more friendly to the lightweight design.

Battery weight energy density = battery capacity discharge platform/weight, the basic unit is Wh/kg (watt hour/kg) Battery volume energy density = battery capacity discharge platform/volume, the basic unit is Wh/L (watt hour/liter) We can supply grams to tons today. the speci c capacity (C) of electrodes determined its energy density (E) like below: E CcCa/(Ca + Cc)(Vc Va) (1) It clearly illustrates that increasing the working voltage of aLIBorcapacityofelectrodescanimproveitsenergydensity.So in the case of anodes, silicon (Si) and lithium (Li) are the two It is believed that this might increase the energy density of lithium-ion batteries by a further 20% to 40%. Unparalleled Safety. Silicon anodes are famous for their energy density, which is 10 times greater than the graphite anodes most often used in today's commercial lithium ion batteries. The biggest advantage of the NCM lithium battery is its high energy density, its energy storage density is usually above 200 Wh/kg, compared to the lithium iron phosphate 90-120 Wh/kg, this performance is more friendly to the lightweight design.  Increase the size of the electrical batteries: Electrical batteries manufacturers can increase the size of the original battery to achieve the effect of capacity expansion. Determine (b): Cell fabrication approach developed by the NIMS-SoftBank Superior Applied sciences Growth Middle. A new lithium-ion battery designed by CalBattery, with a silicon-graphene anode, promises a dramatic energy density breakthrough, according to a news release issued by the company on Friday.

Increase the size of the electrical batteries: Electrical batteries manufacturers can increase the size of the original battery to achieve the effect of capacity expansion. Determine (b): Cell fabrication approach developed by the NIMS-SoftBank Superior Applied sciences Growth Middle. A new lithium-ion battery designed by CalBattery, with a silicon-graphene anode, promises a dramatic energy density breakthrough, according to a news release issued by the company on Friday.  Among the developed batteries, the lithium-ion battery has shown better performance. Amprius claims that its lithium-ion batteries have the highest energy density available, with cells boasting 450 Watt-hours per kilogram (Wh/kg) and 1150 Watt-hours per liter (Wh/L). 1a ). Silicon carbon negative electrode. Obtaining a better energy density will come partly from SolidEnergys Solid Polymer Ionic Liquid (SPIL) electrolyte, which Hu claims, enables use of an ultra-thin lithium metal anode, and improves the cell-level energy density by 50 percent compared to graphite anodes and 30 percent compared to silicon-composite anodes.. How is the energy density of lithium batteries. Cobalt, Manganese, and LPF. A test battery constructed with the silicon anode was shown to have an energy density 25 percent higher than a comparable commercially available battery with a Energy density at cell level ~125Wh/kg (2021) Maximum theoretical cell level energy density ~170Wh/kg; LMO. Jan 27, 2021. The Rocky Mountain Institute surveyed potential battery technologies. Lithium-ion battery energy density big reveal. [Silicon-carbon anode material lithium battery energy far exceeds Tesla Model 3 battery] Amprius company in California has announced that it has produced the first batch of ultra-high energy density lithium battery, which has a battery density of 450Wh/kg (1150 Wh/l), making it the highest energy density lithium battery available at present. The mass-energy density of lithium-ion batteries with silicon cathode materials can be increased by more than 8% and the bulk energy density by more than 10%, while the cost per kWh of the battery can be reduced by at least 3%. And its fully compatible with existing battery manufacturing processes and factories, making the path to progress immediate. One potential replacement material is silicon, and significant research efforts are underway to commercialize so-called lithium-silicon batteries. Our technology optimizes the Enevate anode performance through a combination of electrolyte formulation, cell design, and cell formation. This battery has an energy density of 10 equal to that of a lithium-ion battery and uses air oxygen as the active material of the cathode and anode like a lithium-ion battery Performance of equalizer circuits for lithium-ion cells. A joint research team, affiliated with UNIST has unveiled a novel electrolyte additive that could enable a long lifespan and fast chargeability of high-energy-density Lithium-Ion Batteries (LIBs). battery pack sizes, energy density, chemistry and costs, as well as the rate of growth of the EV market by vehicle Silicon is already playing a key role in increasing energy density At present silicon blending with graphite is on average 4% for automotive applications, at Lithium metal is highly reactive EXAMPLE. Lithiumsulfur battery of practical interest requires thin-layer support to achieve acceptable volumetric energy density. The application prospects of silicon-carbon anode materials are getting brighter and brighter. Sila changes that. Our next-gen silicon material shatters that energy ceiling, improving energy density significantly without compromise. Silicon battery Presentation - Lithium Ion 1. But NanoGrafs silicon-anode battery, Wang said, packs ten percent more energy density than even the industrys top-performing 18650 cells. Jul 27, 2022. The lithium-ion battery market is projected to grow at a CAGR of 13.7% between 2017 and 2022, to a value of USD 67.7 billion. Experimental reports of up to 40% increase in energy density of Si anode based LIBs (Si-LIBs) have been reported in literature. By weight, Amprius Lithium is also a highly reactive element, meaning that a lot of energy can be stored in its atomic bonds. This translates into a very high energy density for lithium-ion batteries. Here is a way to get a perspective on the energy density. A typical lithium-ion battery can store 150 watt-hours of electricity in 1 kilogram of battery. The pure silicon anode is a key battery component. Silicon, as the material with the highest energy density, can take up a remarkable number of lithium ions. What determines the range of a new energy vehicle? By weight, Amprius Lithium-ion batteries (LIBs) have become the preferred power source for various consumer devices such as electronic gadgets due to their high As graphite anodes reach their limit in terms of power and energy density, battery makers are turning to highly-abundant material, silicon. Berdichevsky is well aware of the obstacles to the mass production of an EV-worthy lithium-silicon battery. Lithium and its Applications With an atomic number of 3 & a density of 0.534 g/cm3, Lithium is the first. 1. The above chart demonstrates the space required in a battery cell for the Communications Materials , 2021; 2 (1) DOI: 10.1038/s43246-021 In fact, large-format EV size cells achieve over 1000 Wh/L and 350 Wh/kg energy density. All EV Batteries. Silicon (Si) is under consideration as a potential next-generation anode material for the lithium ion battery (LIB). 18650, Pouch, Prismatic and Medical Device. Experimental reports of up to 40% increase in

Among the developed batteries, the lithium-ion battery has shown better performance. Amprius claims that its lithium-ion batteries have the highest energy density available, with cells boasting 450 Watt-hours per kilogram (Wh/kg) and 1150 Watt-hours per liter (Wh/L). 1a ). Silicon carbon negative electrode. Obtaining a better energy density will come partly from SolidEnergys Solid Polymer Ionic Liquid (SPIL) electrolyte, which Hu claims, enables use of an ultra-thin lithium metal anode, and improves the cell-level energy density by 50 percent compared to graphite anodes and 30 percent compared to silicon-composite anodes.. How is the energy density of lithium batteries. Cobalt, Manganese, and LPF. A test battery constructed with the silicon anode was shown to have an energy density 25 percent higher than a comparable commercially available battery with a Energy density at cell level ~125Wh/kg (2021) Maximum theoretical cell level energy density ~170Wh/kg; LMO. Jan 27, 2021. The Rocky Mountain Institute surveyed potential battery technologies. Lithium-ion battery energy density big reveal. [Silicon-carbon anode material lithium battery energy far exceeds Tesla Model 3 battery] Amprius company in California has announced that it has produced the first batch of ultra-high energy density lithium battery, which has a battery density of 450Wh/kg (1150 Wh/l), making it the highest energy density lithium battery available at present. The mass-energy density of lithium-ion batteries with silicon cathode materials can be increased by more than 8% and the bulk energy density by more than 10%, while the cost per kWh of the battery can be reduced by at least 3%. And its fully compatible with existing battery manufacturing processes and factories, making the path to progress immediate. One potential replacement material is silicon, and significant research efforts are underway to commercialize so-called lithium-silicon batteries. Our technology optimizes the Enevate anode performance through a combination of electrolyte formulation, cell design, and cell formation. This battery has an energy density of 10 equal to that of a lithium-ion battery and uses air oxygen as the active material of the cathode and anode like a lithium-ion battery Performance of equalizer circuits for lithium-ion cells. A joint research team, affiliated with UNIST has unveiled a novel electrolyte additive that could enable a long lifespan and fast chargeability of high-energy-density Lithium-Ion Batteries (LIBs). battery pack sizes, energy density, chemistry and costs, as well as the rate of growth of the EV market by vehicle Silicon is already playing a key role in increasing energy density At present silicon blending with graphite is on average 4% for automotive applications, at Lithium metal is highly reactive EXAMPLE. Lithiumsulfur battery of practical interest requires thin-layer support to achieve acceptable volumetric energy density. The application prospects of silicon-carbon anode materials are getting brighter and brighter. Sila changes that. Our next-gen silicon material shatters that energy ceiling, improving energy density significantly without compromise. Silicon battery Presentation - Lithium Ion 1. But NanoGrafs silicon-anode battery, Wang said, packs ten percent more energy density than even the industrys top-performing 18650 cells. Jul 27, 2022. The lithium-ion battery market is projected to grow at a CAGR of 13.7% between 2017 and 2022, to a value of USD 67.7 billion. Experimental reports of up to 40% increase in energy density of Si anode based LIBs (Si-LIBs) have been reported in literature. By weight, Amprius Lithium is also a highly reactive element, meaning that a lot of energy can be stored in its atomic bonds. This translates into a very high energy density for lithium-ion batteries. Here is a way to get a perspective on the energy density. A typical lithium-ion battery can store 150 watt-hours of electricity in 1 kilogram of battery. The pure silicon anode is a key battery component. Silicon, as the material with the highest energy density, can take up a remarkable number of lithium ions. What determines the range of a new energy vehicle? By weight, Amprius Lithium-ion batteries (LIBs) have become the preferred power source for various consumer devices such as electronic gadgets due to their high As graphite anodes reach their limit in terms of power and energy density, battery makers are turning to highly-abundant material, silicon. Berdichevsky is well aware of the obstacles to the mass production of an EV-worthy lithium-silicon battery. Lithium and its Applications With an atomic number of 3 & a density of 0.534 g/cm3, Lithium is the first. 1. The above chart demonstrates the space required in a battery cell for the Communications Materials , 2021; 2 (1) DOI: 10.1038/s43246-021 In fact, large-format EV size cells achieve over 1000 Wh/L and 350 Wh/kg energy density. All EV Batteries. Silicon (Si) is under consideration as a potential next-generation anode material for the lithium ion battery (LIB). 18650, Pouch, Prismatic and Medical Device. Experimental reports of up to 40% increase in  EVreporter. Lithium iron phosphate, lithium nickel manganese cobalt, silicon, solid-state, sodium-ion. Companys proprietary platform of advanced materials will enable a safer EV battery with higher gravimetric energy density than conventional lithium-ion and solid state technologies. Anode materials include: Silicon: Silicon can store significantly more lithium ions than graphite. Silicon Composite Material For Lithium Battery New Energy Battery Production Line , Find Complete Details about Silicon Composite Material For Lithium Battery New Energy Battery Production Line,Silicon Composite Material For Lithium Battery,New Energy Battery Production Line,Silicon Composite Material from Lithium Ion Batteries Supplier or

EVreporter. Lithium iron phosphate, lithium nickel manganese cobalt, silicon, solid-state, sodium-ion. Companys proprietary platform of advanced materials will enable a safer EV battery with higher gravimetric energy density than conventional lithium-ion and solid state technologies. Anode materials include: Silicon: Silicon can store significantly more lithium ions than graphite. Silicon Composite Material For Lithium Battery New Energy Battery Production Line , Find Complete Details about Silicon Composite Material For Lithium Battery New Energy Battery Production Line,Silicon Composite Material For Lithium Battery,New Energy Battery Production Line,Silicon Composite Material from Lithium Ion Batteries Supplier or  Stanford University scientists have dramatically improved the performance of lithium-ion batteries by creating novel electrodes made of silicon and conducting polymer hydrogel, a spongy material similar to that used in contact lenses and other household products. There are four key parts of a lithium battery: anode, cathode, electrode and diaphragm, which all affect the batterys energy density. As consumer demand grows for battery-enabled technology, manufacturers are investing in battery research and development, with the goal of speeding the advancement of energy density in lithium-ion batteries. Will a 3X improvement in anode performance translate into a 3X improvement in energy density of the overall battery, or not? However, significant challenges such as short cycle life and low coulombic efficiency have seriously hindered Determine (a): New supplies for lithium-air batteries developed by ALCA-SPRING venture. Lithium air batteries could increase energy density by ten times. Silicon holds on to nine times more lithium ions than graphite does, so it has better energy density (thus expanding range by 20 percent). The energy density of lithium battery cells mainly depends on the breakthrough of the chemical system. Silicon is an earth abundant element, and is fairly inexpensive to refine to high purity.When alloyed with lithium it has a theoretical capacity of ~3,600 milliampere hours per gram (mAh/g), which is nearly 10 times the energy density of graphite electrodes, which exhibit a maximum capacity of 372 mAh/g for their fully lithiated state of LiC 6. However, this increase in energy density is achieved wh Skip to content. SiFAB has engineered a unique nanoporous fiber structure that accommodates swelling of silicon in lithium-ion batteries. By focusing on silicon anode technology, it claims

Stanford University scientists have dramatically improved the performance of lithium-ion batteries by creating novel electrodes made of silicon and conducting polymer hydrogel, a spongy material similar to that used in contact lenses and other household products. There are four key parts of a lithium battery: anode, cathode, electrode and diaphragm, which all affect the batterys energy density. As consumer demand grows for battery-enabled technology, manufacturers are investing in battery research and development, with the goal of speeding the advancement of energy density in lithium-ion batteries. Will a 3X improvement in anode performance translate into a 3X improvement in energy density of the overall battery, or not? However, significant challenges such as short cycle life and low coulombic efficiency have seriously hindered Determine (a): New supplies for lithium-air batteries developed by ALCA-SPRING venture. Lithium air batteries could increase energy density by ten times. Silicon holds on to nine times more lithium ions than graphite does, so it has better energy density (thus expanding range by 20 percent). The energy density of lithium battery cells mainly depends on the breakthrough of the chemical system. Silicon is an earth abundant element, and is fairly inexpensive to refine to high purity.When alloyed with lithium it has a theoretical capacity of ~3,600 milliampere hours per gram (mAh/g), which is nearly 10 times the energy density of graphite electrodes, which exhibit a maximum capacity of 372 mAh/g for their fully lithiated state of LiC 6. However, this increase in energy density is achieved wh Skip to content. SiFAB has engineered a unique nanoporous fiber structure that accommodates swelling of silicon in lithium-ion batteries. By focusing on silicon anode technology, it claims  The lithium-ion batteries that sustain our lives arent equipped to power our future. Silicon coated carbon nanotubes and fibers and silicon and porous silicon-carbon composite The development of the new battery focused on commercialization from the outset. Wh/liter Wh/kg Independent patent filings on nanowire technology and lithium ion cells Silicon nanowire anode. Lithium ion batteries (LIBs) play a signi cantly important role in various energy storage technologies because of their high energy density.14 Since the rst commercial LIB came out in 1991, it has played Team develops stable, efficient, anode-free sodium battery. Our silicon anode products enable a leap in lithium-ion battery energy and power density. The increasing development of batterypowered vehicles for exceeding 500 km endurance has stimulated the exploration of lithium batteries with highenergydensity and highpowerdensity.

The lithium-ion batteries that sustain our lives arent equipped to power our future. Silicon coated carbon nanotubes and fibers and silicon and porous silicon-carbon composite The development of the new battery focused on commercialization from the outset. Wh/liter Wh/kg Independent patent filings on nanowire technology and lithium ion cells Silicon nanowire anode. Lithium ion batteries (LIBs) play a signi cantly important role in various energy storage technologies because of their high energy density.14 Since the rst commercial LIB came out in 1991, it has played Team develops stable, efficient, anode-free sodium battery. Our silicon anode products enable a leap in lithium-ion battery energy and power density. The increasing development of batterypowered vehicles for exceeding 500 km endurance has stimulated the exploration of lithium batteries with highenergydensity and highpowerdensity.  Jun 3, 2013. As the search continues for high-performing lithium-based battery systems, new combinations of materials and ideas are showing promise.

Jun 3, 2013. As the search continues for high-performing lithium-based battery systems, new combinations of materials and ideas are showing promise.