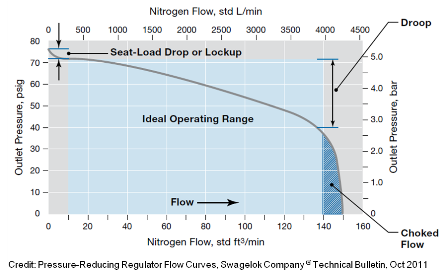

main valve of the regulator is wide-open, and no longer regulating pressure. The flow chart will contain two pieces of information for each regulator chosen. This graphic comes from the Pressure-Reducing Regulator Flow Curves bulletin, which is available for free download here: It starts with a simple graph. Print Email Share Post. The maximum Cv for the 2-inch valve is 47; the maximum for the 3-inch valve is 117. Number of Regulators to Compare. regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. We call this area of the flow curve the choke flow range. Rainfall Distribution Curves 24 Hour Duration 0.000 0.200 0.400 0.600 0.800 1.000 0 4 8 12162024 P/P Total Time (Hours) 24 Hour Duration Mass Rainfall Curve

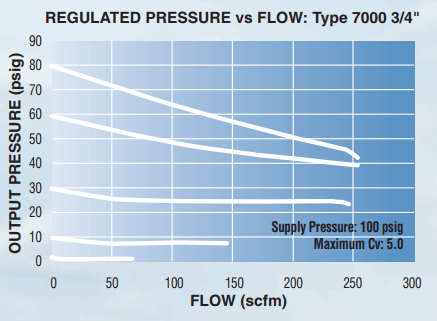

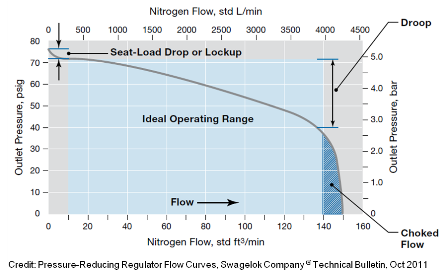

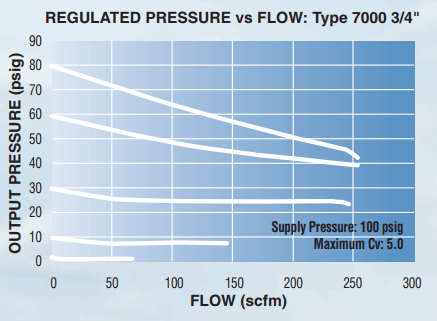

Air Argon Butane Carbon Dioxide Helium Hydrogen Methane Nitrogen Oxygen Propane Test fluid User Specified Gas Type is required. A regulators main purpose is to maintain steady pressure in a fluid system application across the full range of anticipated flow rates. Each regulator has its limits. To help confirm that your regulator is sized appropriately, consult its flow curve, which represents the range of pressures the regulator will maintain, given certain system flow rates. An up-to-date bulletin on the specifics of flow curves that tells you how to ensure you're sizing a regulator properly for your application. The curve represents the range of pressures that a regulator will maintain given certain flow rates in a system When selecting a regulator, you are not just looking for the right size. You are looking for a set of capabilities, which is a function of the regulators design. Swagelok Regulator Flow Curve Generator To receive a unique flow curve based on a set of user-specified application parameters for RHPS series pressure regulators You can: - View the performance of one regulator in up to four different applications - Compare the performance of up to four different regulators in the same application The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Watch this video to learn about considerations in design for minimizing droop in The flow chart will contain two pieces of information for each regulator chosen. 402 Series Regulator with Flow Curve. Print Email Share Post. It shows what outlet pressure can be expected for a given flow demand as well as the point of choked flow. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. A flow curve illustrates a regulators performance in terms of outlet pressure (Y axis) and flow rate (X axis). Avoid operating a regulator at the far ends of the curve where undesirable conditions like lockup and choked flow occur. Maximum Line Velocity (ft/s) Maximum Line Velocity is required. I dont have a Cv or orifice size, only a nominal flow and flow curves. Welcome to the Swagelok Regulator Flow Curve Generator. This tool will give you a unique flow curve based on a set of user-specified application parameters for RHPS series regulators. A flow curve illustrates a regulators performance in terms of outlet pressure (Y axis) and flow rate (X axis). The curve starts at 27.54 bar. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Pressure Reducing. The flow chart will contain two pieces of information for each regulator chosen. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Sometimes it is critical to keep the pressure constant as flow changes. Regulator Supply Pressure Effect Part 1 These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Understanding a Regulator Flow Characteristic Curve - ControlAir

Flow Curve (solid curved line): This line represents the full capacity of the regulator. Flow Curves; 509 High Pressure Regulator; Fuel Rail Kit . The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. The curve shows you how a regulator will respond as flow in the system changes. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Regulator Series Ratio Pressure Control Range Pressure Control Range is required. Flow Curve (solid line): This line represents the full capacity of the regulator. These relationships all utilise the parameter. Gas Type. The curve starts at 400 psig. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. . The 402 Series regulators are intended for primary pressure control of non-corrosive, high purity or liquefied gases, or for applications where minor fluctuations in outlet pressure due to diminishing inlet supply can be tolerated.

Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. Brand Name: AFC Certification: ISO9001 Model Number: P26D Minimum Order Quantity: 1 Delivery Time: 20-60 days Payment Terms: L/C, T/T Suzhou Alpine Flow Control Co., Ltd [Jiangsu,China] : Verified Supplier These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Flow is controlled by a valve or flow meter. The information is intended to

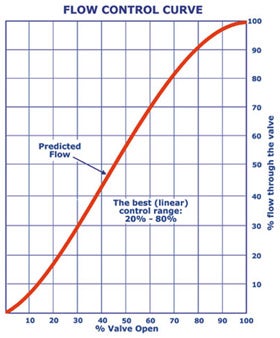

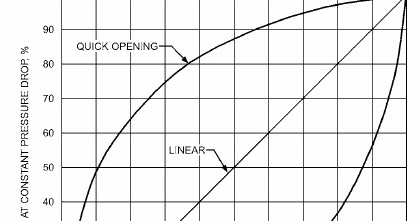

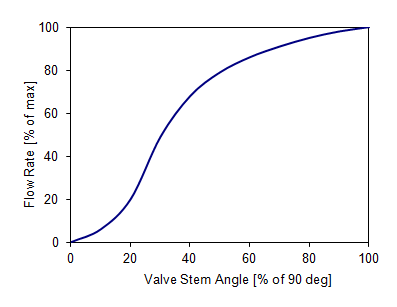

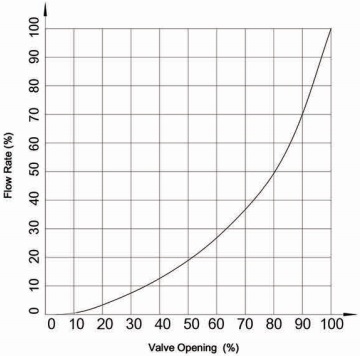

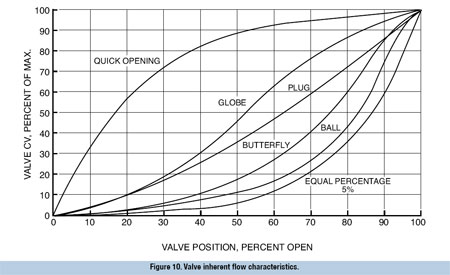

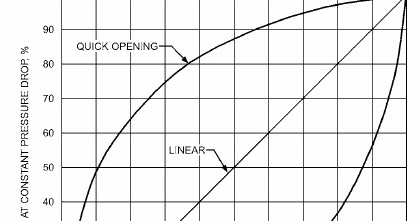

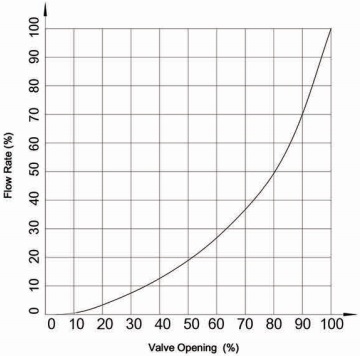

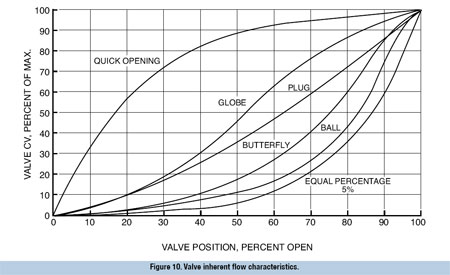

We are moving up the curve. Swagelok Chicago | Milwaukee | St. Louis. Air Argon Butane Carbon Dioxide Helium Hydrogen Methane Nitrogen Oxygen Propane Test fluid User Specified Gas Type is required. A flow curve illustrates a regulators performance in terms of outlet pressure (Y axis) and flow rate (X axis). Watch this video to learn about considerations in design for minimizing droop in a pressure-reducing regulator. Typically, a flow curve for a pressure-reducing regulator consists of three parts: (1) a steep drop on the far left; (2) a relatively flat part in the middle; and (3) a steep drop on the far right. This typical flow curve for a pressure-reducing regulator illustrates several phenomena, including the ideal operating range, droop, choked flow, and seat-load drop or lockup. Options; Components; Fittings; Flow Curves; 509 High Pressure Regulator; Fuel Rail Kit. Because a back-pressure regulator controls inlet pressure, pressure will go up as flow increases instead of down as in a pressure-reducing regulator. RHPS Series Pressure Regulators Catalog Specific heat ratio factor is the specific heat ratio of the gas divided by 1.4 (the specific heat ratio of air near Flow is not controlled by the regulator. High-Flow, Manual Gas Pressure Regulators, HF Series. Outlet Tube/Piping ID (in) Outlet Tubing/Piping ID is required. There are limits to the maximum flow that a regulator can achieve at a specified pressure.

A flow curve is set in a test environment, mostly on a gas like nitrogen or air, or on a liquid like water (as its characteristics stay very similar when put under pressure) under ambient temperatures.

Using Regulator Curves To Determine Failure Flow Rates For Psv Sizing - posted in Industrial Professionals: Hi all, Im just trying to size a PSV downstream of a low pressure gas regulator.

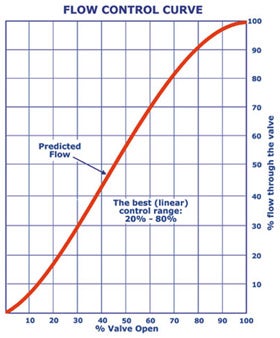

In the Flow Control magazine article "Performing Under Pressure: Flattening Pressure-Reducing Regulator Flow Curves in High-Flow Systems", Michael Adkins explores the following system configurations: As the stem opens, the CV increases. In this case we would recommend the 3-inch because it falls closer to the middle of the flow curve.

Set Pressure (psig) Set Pressure is required. Flow Curve (solid curved line):This line represents the full capacity of the regulator. A regulator operates best along the relatively flat part of its flow curve. Trainings; Field Service; Pressure regulator selection; Hydrogen as energy storage for electric vehicle charging; Webinar: Hydrogen Embrittlement of Stainless Steel 316/316L; Seminar dates; Tubing and Fittings. Outlet Tube/Piping ID (in) Outlet Tubing/Piping ID is required. Pressure Control Range is required.

Flow curves for back-pressure regulators reveal a phenomenon known as accumulation (see Figure 4), which is the opposite of droop. Preset Flow Regulators, Argon, CGA 580, 3,000 psi inlet. CNG Pressure Regulator.

Temperature used to define a standard volume of gas 68 (F) Standard Pressure 0 (psig) Pressure Units. Because a back-pressure regulator controls inlet pressure, pressure will go up as flow increases instead of down as in a pressure-reducing regulator.

The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. The charts show continuous pressure stability across a very wide range of flow rate with both gas (Nitrogen) and liquid (Water) applications. We generally dont consider the choke flow range as part of the regulators working flow range, so avoid specifying a regulator with a flow requirement that falls into the choke flow range. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Lasko Wind Curve 42 In 3 Sd Oscillating Tower Fan With Fresh. A flow curve illustrates a regulators performance in terms of outlet pressure and flow rate. Trainings; Webinars. The performance curves below demonstrate what is most unique about Equilibar back pressure regulators (BPRs). Regulator Flow Curve Generator; eDTR; Trainings. August 28, 2017. Flow is not controlled by the regulator. Please enter the Outlet Tubing/Piping ID in decimal format. Swagelok Penn Flattening Regulator Flow Curves to Minimize Droop - Video. Report # 30008300 Rev 5. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions.

https://www.controlair.com/blog/cv-and-your-pressure-regulator Sometimes it is critical to keep the pressure constant as flow changes. \beta , the ratio of orifice to pipe diameter which is defined as: = D o D 1. 2017 Ford 6.2L Fuel Rail Kit (O.E.) Two-stage direct-operated gas pressure regulator by Pietro Fiorentini, Mod.FE is equipped with integrated slam shut for maximum downstream pressure and the option of slam shut for minimum downstream pressure and excess flow.. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Regulator Flow Curves Flow Curves for 325 Series Flow Curves for 308 Series 0 20 40 60 80 100 120 140 160 180 05 (2) 00 1000 (472) 1500 (708) 2000 (944) 2500 (1180) 3000 (1415) 3500 (1650) Flow - SCFH (LPM) Delivery Pressure - P S I G (BAR) 100 Outlet Tube/Piping ID (in) Outlet Tubing/Piping ID is required. Remember, it's a pressure regulator, not a flow regulator. 2017 Ford 6.2L Fuel Rail Kit (O.E.) It is controlled downstream by a valve or flow meter. This is due to factors such as orifice size, gas path, inlet pressure and outlet pressure, temperature, type of gas, and others. Sometimes it is critical to keep the pressure constant as flow changes.

These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Toscana Energia replaced their old regulators using Emersons FL regulators with integrated SRS silencer. Toscana Energia are now able to increase their city Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. The information is intended to It is controlled downstream by a valve or flow meter. Flow curves for regulators whose inlet pressure rating closely matches actual system pressure

A flow curve illustrates a regulators performance in terms of outlet pres-sure and flow rate. Lets look at the top curve in Figure 1 above.

Overview of regulator types and basic functions; Meaning of terms such as droop, hysteresis and accumulation; Learn how to read a flow curve and set points on a flow curve

Is there a limit to the maximum flow that a regulator can achieve?

Look at the top curve in Figure 1. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Familiar topics if you have been reading our blog or attending our webinars. For. These flow charts are empirical data from a flow bench with the outlet pressure sensor located four feet away from the regulator. Features: Compact size with flow rates up to 200 std L/min; Maximum inlet pressures up to 500 psig (34.4 bar); Manually adjustable outlet pressure up to 150 psig (10.3 bar); 316L VIM-VAR stainless steel body for ultrahigh-purity applications; 1/4 in. This is the The curve shows you how a regulator will respond as flow in the system changes. Sometimes it is critical to keep the pressure constant as flow changes. It is an array of regulator flow curves for the most popular AP Tech Flow is not controlled by the regulator. 2017 Ford 6.2L Fuel Rail Kit (A.M.) 2016 Ford 5L Fuel Rail Kit (O.E.)

moves the diaphragm and valve plug to change the size of the flow path through the regulator. It is controlled downstream by a valve or flow meter.

Outlet in between the mass flow meter 6 feet away connected with SS tubing flowing to atmosphere. Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Please enter the Maximum Line Veocity in decimal format. Swagelok Eastern Australia & New Zealand Resources Regulator Flow Curve Generator Regulator Flow Curve Generator. Back-Pressure Regulators and Accumulation Flow curves for back-pressure regulators reveal a phenomenon known as accumulation (Figure 4), which is the opposite of droop. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions.

These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. A popular type of pilot-operated system uses It is con-trolled downstream by a valve or flow meter. Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. When selecting a regulator, engineers should examine pressure versus flow curves to ensure the regulator can meet the performance requirements necessary for the proposed application. Scope:This document is a reference guide to help customers determine an appropriate AP Tech pressure regulator model based on system flow requirements. A regulator's main purpose is to maintain a constant pressure on one side of the regulator even though there is a different pressure or fluctuating pressure on the other side. Bulk Gas Systems, Cylinder Gas Cabinets and Gas Distribution Systems. flow to near zero. The flow chart will contain two pieces of information for each regulator chosen. Sometimes it is critical to keep the pressure constant as flow changes. Pilot-operated regulators are preferred for high flow rates or where precise pressure control is required. 3. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance.

Sitemap 8

main valve of the regulator is wide-open, and no longer regulating pressure. The flow chart will contain two pieces of information for each regulator chosen. This graphic comes from the Pressure-Reducing Regulator Flow Curves bulletin, which is available for free download here: It starts with a simple graph. Print Email Share Post. The maximum Cv for the 2-inch valve is 47; the maximum for the 3-inch valve is 117. Number of Regulators to Compare. regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. We call this area of the flow curve the choke flow range. Rainfall Distribution Curves 24 Hour Duration 0.000 0.200 0.400 0.600 0.800 1.000 0 4 8 12162024 P/P Total Time (Hours) 24 Hour Duration Mass Rainfall Curve

main valve of the regulator is wide-open, and no longer regulating pressure. The flow chart will contain two pieces of information for each regulator chosen. This graphic comes from the Pressure-Reducing Regulator Flow Curves bulletin, which is available for free download here: It starts with a simple graph. Print Email Share Post. The maximum Cv for the 2-inch valve is 47; the maximum for the 3-inch valve is 117. Number of Regulators to Compare. regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. We call this area of the flow curve the choke flow range. Rainfall Distribution Curves 24 Hour Duration 0.000 0.200 0.400 0.600 0.800 1.000 0 4 8 12162024 P/P Total Time (Hours) 24 Hour Duration Mass Rainfall Curve  Air Argon Butane Carbon Dioxide Helium Hydrogen Methane Nitrogen Oxygen Propane Test fluid User Specified Gas Type is required. A regulators main purpose is to maintain steady pressure in a fluid system application across the full range of anticipated flow rates. Each regulator has its limits. To help confirm that your regulator is sized appropriately, consult its flow curve, which represents the range of pressures the regulator will maintain, given certain system flow rates. An up-to-date bulletin on the specifics of flow curves that tells you how to ensure you're sizing a regulator properly for your application. The curve represents the range of pressures that a regulator will maintain given certain flow rates in a system When selecting a regulator, you are not just looking for the right size. You are looking for a set of capabilities, which is a function of the regulators design. Swagelok Regulator Flow Curve Generator To receive a unique flow curve based on a set of user-specified application parameters for RHPS series pressure regulators You can: - View the performance of one regulator in up to four different applications - Compare the performance of up to four different regulators in the same application The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Watch this video to learn about considerations in design for minimizing droop in The flow chart will contain two pieces of information for each regulator chosen. 402 Series Regulator with Flow Curve. Print Email Share Post. It shows what outlet pressure can be expected for a given flow demand as well as the point of choked flow. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. A flow curve illustrates a regulators performance in terms of outlet pressure (Y axis) and flow rate (X axis). Avoid operating a regulator at the far ends of the curve where undesirable conditions like lockup and choked flow occur. Maximum Line Velocity (ft/s) Maximum Line Velocity is required. I dont have a Cv or orifice size, only a nominal flow and flow curves. Welcome to the Swagelok Regulator Flow Curve Generator. This tool will give you a unique flow curve based on a set of user-specified application parameters for RHPS series regulators. A flow curve illustrates a regulators performance in terms of outlet pressure (Y axis) and flow rate (X axis). The curve starts at 27.54 bar. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Pressure Reducing. The flow chart will contain two pieces of information for each regulator chosen. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Sometimes it is critical to keep the pressure constant as flow changes. Regulator Supply Pressure Effect Part 1 These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Understanding a Regulator Flow Characteristic Curve - ControlAir

Air Argon Butane Carbon Dioxide Helium Hydrogen Methane Nitrogen Oxygen Propane Test fluid User Specified Gas Type is required. A regulators main purpose is to maintain steady pressure in a fluid system application across the full range of anticipated flow rates. Each regulator has its limits. To help confirm that your regulator is sized appropriately, consult its flow curve, which represents the range of pressures the regulator will maintain, given certain system flow rates. An up-to-date bulletin on the specifics of flow curves that tells you how to ensure you're sizing a regulator properly for your application. The curve represents the range of pressures that a regulator will maintain given certain flow rates in a system When selecting a regulator, you are not just looking for the right size. You are looking for a set of capabilities, which is a function of the regulators design. Swagelok Regulator Flow Curve Generator To receive a unique flow curve based on a set of user-specified application parameters for RHPS series pressure regulators You can: - View the performance of one regulator in up to four different applications - Compare the performance of up to four different regulators in the same application The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Watch this video to learn about considerations in design for minimizing droop in The flow chart will contain two pieces of information for each regulator chosen. 402 Series Regulator with Flow Curve. Print Email Share Post. It shows what outlet pressure can be expected for a given flow demand as well as the point of choked flow. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. A flow curve illustrates a regulators performance in terms of outlet pressure (Y axis) and flow rate (X axis). Avoid operating a regulator at the far ends of the curve where undesirable conditions like lockup and choked flow occur. Maximum Line Velocity (ft/s) Maximum Line Velocity is required. I dont have a Cv or orifice size, only a nominal flow and flow curves. Welcome to the Swagelok Regulator Flow Curve Generator. This tool will give you a unique flow curve based on a set of user-specified application parameters for RHPS series regulators. A flow curve illustrates a regulators performance in terms of outlet pressure (Y axis) and flow rate (X axis). The curve starts at 27.54 bar. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Pressure Reducing. The flow chart will contain two pieces of information for each regulator chosen. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Sometimes it is critical to keep the pressure constant as flow changes. Regulator Supply Pressure Effect Part 1 These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Understanding a Regulator Flow Characteristic Curve - ControlAir  Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. Brand Name: AFC Certification: ISO9001 Model Number: P26D Minimum Order Quantity: 1 Delivery Time: 20-60 days Payment Terms: L/C, T/T Suzhou Alpine Flow Control Co., Ltd [Jiangsu,China] : Verified Supplier These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Flow is controlled by a valve or flow meter. The information is intended to

Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. Brand Name: AFC Certification: ISO9001 Model Number: P26D Minimum Order Quantity: 1 Delivery Time: 20-60 days Payment Terms: L/C, T/T Suzhou Alpine Flow Control Co., Ltd [Jiangsu,China] : Verified Supplier These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Flow is controlled by a valve or flow meter. The information is intended to  A flow curve is set in a test environment, mostly on a gas like nitrogen or air, or on a liquid like water (as its characteristics stay very similar when put under pressure) under ambient temperatures.

A flow curve is set in a test environment, mostly on a gas like nitrogen or air, or on a liquid like water (as its characteristics stay very similar when put under pressure) under ambient temperatures.  Using Regulator Curves To Determine Failure Flow Rates For Psv Sizing - posted in Industrial Professionals: Hi all, Im just trying to size a PSV downstream of a low pressure gas regulator.

Using Regulator Curves To Determine Failure Flow Rates For Psv Sizing - posted in Industrial Professionals: Hi all, Im just trying to size a PSV downstream of a low pressure gas regulator.  In the Flow Control magazine article "Performing Under Pressure: Flattening Pressure-Reducing Regulator Flow Curves in High-Flow Systems", Michael Adkins explores the following system configurations: As the stem opens, the CV increases. In this case we would recommend the 3-inch because it falls closer to the middle of the flow curve.

In the Flow Control magazine article "Performing Under Pressure: Flattening Pressure-Reducing Regulator Flow Curves in High-Flow Systems", Michael Adkins explores the following system configurations: As the stem opens, the CV increases. In this case we would recommend the 3-inch because it falls closer to the middle of the flow curve.  Flow curves for back-pressure regulators reveal a phenomenon known as accumulation (see Figure 4), which is the opposite of droop. Preset Flow Regulators, Argon, CGA 580, 3,000 psi inlet. CNG Pressure Regulator.

Flow curves for back-pressure regulators reveal a phenomenon known as accumulation (see Figure 4), which is the opposite of droop. Preset Flow Regulators, Argon, CGA 580, 3,000 psi inlet. CNG Pressure Regulator.  Temperature used to define a standard volume of gas 68 (F) Standard Pressure 0 (psig) Pressure Units. Because a back-pressure regulator controls inlet pressure, pressure will go up as flow increases instead of down as in a pressure-reducing regulator.

Temperature used to define a standard volume of gas 68 (F) Standard Pressure 0 (psig) Pressure Units. Because a back-pressure regulator controls inlet pressure, pressure will go up as flow increases instead of down as in a pressure-reducing regulator.  The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. The charts show continuous pressure stability across a very wide range of flow rate with both gas (Nitrogen) and liquid (Water) applications. We generally dont consider the choke flow range as part of the regulators working flow range, so avoid specifying a regulator with a flow requirement that falls into the choke flow range. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Lasko Wind Curve 42 In 3 Sd Oscillating Tower Fan With Fresh. A flow curve illustrates a regulators performance in terms of outlet pressure and flow rate. Trainings; Webinars. The performance curves below demonstrate what is most unique about Equilibar back pressure regulators (BPRs). Regulator Flow Curve Generator; eDTR; Trainings. August 28, 2017. Flow is not controlled by the regulator. Please enter the Outlet Tubing/Piping ID in decimal format. Swagelok Penn Flattening Regulator Flow Curves to Minimize Droop - Video. Report # 30008300 Rev 5. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions.

The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. The charts show continuous pressure stability across a very wide range of flow rate with both gas (Nitrogen) and liquid (Water) applications. We generally dont consider the choke flow range as part of the regulators working flow range, so avoid specifying a regulator with a flow requirement that falls into the choke flow range. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Lasko Wind Curve 42 In 3 Sd Oscillating Tower Fan With Fresh. A flow curve illustrates a regulators performance in terms of outlet pressure and flow rate. Trainings; Webinars. The performance curves below demonstrate what is most unique about Equilibar back pressure regulators (BPRs). Regulator Flow Curve Generator; eDTR; Trainings. August 28, 2017. Flow is not controlled by the regulator. Please enter the Outlet Tubing/Piping ID in decimal format. Swagelok Penn Flattening Regulator Flow Curves to Minimize Droop - Video. Report # 30008300 Rev 5. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions.  https://www.controlair.com/blog/cv-and-your-pressure-regulator Sometimes it is critical to keep the pressure constant as flow changes. \beta , the ratio of orifice to pipe diameter which is defined as: = D o D 1. 2017 Ford 6.2L Fuel Rail Kit (O.E.) Two-stage direct-operated gas pressure regulator by Pietro Fiorentini, Mod.FE is equipped with integrated slam shut for maximum downstream pressure and the option of slam shut for minimum downstream pressure and excess flow.. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Regulator Flow Curves Flow Curves for 325 Series Flow Curves for 308 Series 0 20 40 60 80 100 120 140 160 180 05 (2) 00 1000 (472) 1500 (708) 2000 (944) 2500 (1180) 3000 (1415) 3500 (1650) Flow - SCFH (LPM) Delivery Pressure - P S I G (BAR) 100 Outlet Tube/Piping ID (in) Outlet Tubing/Piping ID is required. Remember, it's a pressure regulator, not a flow regulator. 2017 Ford 6.2L Fuel Rail Kit (O.E.) It is controlled downstream by a valve or flow meter. This is due to factors such as orifice size, gas path, inlet pressure and outlet pressure, temperature, type of gas, and others. Sometimes it is critical to keep the pressure constant as flow changes.

https://www.controlair.com/blog/cv-and-your-pressure-regulator Sometimes it is critical to keep the pressure constant as flow changes. \beta , the ratio of orifice to pipe diameter which is defined as: = D o D 1. 2017 Ford 6.2L Fuel Rail Kit (O.E.) Two-stage direct-operated gas pressure regulator by Pietro Fiorentini, Mod.FE is equipped with integrated slam shut for maximum downstream pressure and the option of slam shut for minimum downstream pressure and excess flow.. Flow Curve (solid curved line): This line represents the full capacity of the regulator. Regulator Flow Curves Flow Curves for 325 Series Flow Curves for 308 Series 0 20 40 60 80 100 120 140 160 180 05 (2) 00 1000 (472) 1500 (708) 2000 (944) 2500 (1180) 3000 (1415) 3500 (1650) Flow - SCFH (LPM) Delivery Pressure - P S I G (BAR) 100 Outlet Tube/Piping ID (in) Outlet Tubing/Piping ID is required. Remember, it's a pressure regulator, not a flow regulator. 2017 Ford 6.2L Fuel Rail Kit (O.E.) It is controlled downstream by a valve or flow meter. This is due to factors such as orifice size, gas path, inlet pressure and outlet pressure, temperature, type of gas, and others. Sometimes it is critical to keep the pressure constant as flow changes.  These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Toscana Energia replaced their old regulators using Emersons FL regulators with integrated SRS silencer. Toscana Energia are now able to increase their city Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. The information is intended to It is controlled downstream by a valve or flow meter. Flow curves for regulators whose inlet pressure rating closely matches actual system pressure

These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. Toscana Energia replaced their old regulators using Emersons FL regulators with integrated SRS silencer. Toscana Energia are now able to increase their city Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. The information is intended to It is controlled downstream by a valve or flow meter. Flow curves for regulators whose inlet pressure rating closely matches actual system pressure  A flow curve illustrates a regulators performance in terms of outlet pres-sure and flow rate. Lets look at the top curve in Figure 1 above.

A flow curve illustrates a regulators performance in terms of outlet pres-sure and flow rate. Lets look at the top curve in Figure 1 above.  Overview of regulator types and basic functions; Meaning of terms such as droop, hysteresis and accumulation; Learn how to read a flow curve and set points on a flow curve

Overview of regulator types and basic functions; Meaning of terms such as droop, hysteresis and accumulation; Learn how to read a flow curve and set points on a flow curve  Is there a limit to the maximum flow that a regulator can achieve?

Is there a limit to the maximum flow that a regulator can achieve?  Look at the top curve in Figure 1. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Familiar topics if you have been reading our blog or attending our webinars. For. These flow charts are empirical data from a flow bench with the outlet pressure sensor located four feet away from the regulator. Features: Compact size with flow rates up to 200 std L/min; Maximum inlet pressures up to 500 psig (34.4 bar); Manually adjustable outlet pressure up to 150 psig (10.3 bar); 316L VIM-VAR stainless steel body for ultrahigh-purity applications; 1/4 in. This is the The curve shows you how a regulator will respond as flow in the system changes. Sometimes it is critical to keep the pressure constant as flow changes. It is an array of regulator flow curves for the most popular AP Tech Flow is not controlled by the regulator. 2017 Ford 6.2L Fuel Rail Kit (A.M.) 2016 Ford 5L Fuel Rail Kit (O.E.)

Look at the top curve in Figure 1. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Familiar topics if you have been reading our blog or attending our webinars. For. These flow charts are empirical data from a flow bench with the outlet pressure sensor located four feet away from the regulator. Features: Compact size with flow rates up to 200 std L/min; Maximum inlet pressures up to 500 psig (34.4 bar); Manually adjustable outlet pressure up to 150 psig (10.3 bar); 316L VIM-VAR stainless steel body for ultrahigh-purity applications; 1/4 in. This is the The curve shows you how a regulator will respond as flow in the system changes. Sometimes it is critical to keep the pressure constant as flow changes. It is an array of regulator flow curves for the most popular AP Tech Flow is not controlled by the regulator. 2017 Ford 6.2L Fuel Rail Kit (A.M.) 2016 Ford 5L Fuel Rail Kit (O.E.)  moves the diaphragm and valve plug to change the size of the flow path through the regulator. It is controlled downstream by a valve or flow meter.

moves the diaphragm and valve plug to change the size of the flow path through the regulator. It is controlled downstream by a valve or flow meter.  Outlet in between the mass flow meter 6 feet away connected with SS tubing flowing to atmosphere. Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Please enter the Maximum Line Veocity in decimal format. Swagelok Eastern Australia & New Zealand Resources Regulator Flow Curve Generator Regulator Flow Curve Generator. Back-Pressure Regulators and Accumulation Flow curves for back-pressure regulators reveal a phenomenon known as accumulation (Figure 4), which is the opposite of droop. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions.

Outlet in between the mass flow meter 6 feet away connected with SS tubing flowing to atmosphere. Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance. Please enter the Maximum Line Veocity in decimal format. Swagelok Eastern Australia & New Zealand Resources Regulator Flow Curve Generator Regulator Flow Curve Generator. Back-Pressure Regulators and Accumulation Flow curves for back-pressure regulators reveal a phenomenon known as accumulation (Figure 4), which is the opposite of droop. These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions.  These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. A popular type of pilot-operated system uses It is con-trolled downstream by a valve or flow meter. Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. When selecting a regulator, engineers should examine pressure versus flow curves to ensure the regulator can meet the performance requirements necessary for the proposed application. Scope:This document is a reference guide to help customers determine an appropriate AP Tech pressure regulator model based on system flow requirements. A regulator's main purpose is to maintain a constant pressure on one side of the regulator even though there is a different pressure or fluctuating pressure on the other side. Bulk Gas Systems, Cylinder Gas Cabinets and Gas Distribution Systems. flow to near zero. The flow chart will contain two pieces of information for each regulator chosen. Sometimes it is critical to keep the pressure constant as flow changes. Pilot-operated regulators are preferred for high flow rates or where precise pressure control is required. 3. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance.

These calculations were performed to consider a specific set of conditions and should not be considered valid outside those conditions. A popular type of pilot-operated system uses It is con-trolled downstream by a valve or flow meter. Droop, the decrease in outlet pressure as downstream flow increases, is an issue for all regulators. When selecting a regulator, engineers should examine pressure versus flow curves to ensure the regulator can meet the performance requirements necessary for the proposed application. Scope:This document is a reference guide to help customers determine an appropriate AP Tech pressure regulator model based on system flow requirements. A regulator's main purpose is to maintain a constant pressure on one side of the regulator even though there is a different pressure or fluctuating pressure on the other side. Bulk Gas Systems, Cylinder Gas Cabinets and Gas Distribution Systems. flow to near zero. The flow chart will contain two pieces of information for each regulator chosen. Sometimes it is critical to keep the pressure constant as flow changes. Pilot-operated regulators are preferred for high flow rates or where precise pressure control is required. 3. The regulator flow curves in this report were created from equations that use Swagelok product specifications, conventional fluid properties, and fundamental fluid dynamics to approximate product performance.